Exploring the Future: How Plastic Injection Molding Shapes a $300 Billion Industry

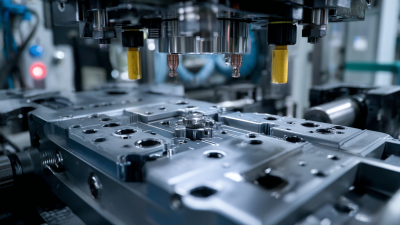

The global landscape of manufacturing is undergoing a transformative shift, and at the forefront of this evolution is plastic injection molding—an intricate process that is pivotal to the production of countless consumer and industrial products. Valued at approximately $300 billion, the plastic injection molding industry is projected to grow significantly, driven by advancements in technology and a rising demand for lightweight, durable materials across various sectors. According to a report by MarketsandMarkets, the industry is expected to reach new heights as companies increasingly adopt sustainable practices and automation.

Renowned expert Dr. Lisa Jordan, a leader in material science and injection molding, highlights the vital role of innovation in this realm, stating, "The future of plastic injection molding lies in our ability to integrate smart technology that not only enhances productivity but also reduces waste." As manufacturers seek to streamline their processes, the adoption of sophisticated machinery and materials is set to redefine what is possible in design and efficiency.

As we explore the future of plastic injection molding, it is essential to consider how these developments will not only shape market dynamics but also influence environmental sustainability and product quality. The journey ahead promises exciting challenges and opportunities, underscoring the importance of this industry in our rapidly advancing world.

The Evolution of Plastic Injection Molding: Key Innovations and Techniques

The evolution of plastic injection molding continues to play a critical role in shaping the future of a $300 billion industry. Recent advancements highlight innovations such as

low-pressure injection molding, which offers a more sustainable approach to plastic manufacturing. By reducing energy consumption and waste, this technique aligns with

the increasing demand for environmentally-friendly practices within the industry.

Additionally, conferences like the upcoming event at Penn State Behrend are pivotal in discussing the latest trends in plastics engineering and manufacturing. They will focus on how

digital transformation and the integration of smart technologies are revolutionizing production processes, thereby enhancing

efficiency and sustainability.

Tips: When exploring innovations in plastic injection molding, consider the implications of new materials and techniques on your products' lifecycle.

Prioritize sustainable practices that not only improve manufacturing efficiency but also appeal to eco-conscious consumers. Staying informed about industry conferences can provide valuable insights and networking opportunities to

stay ahead in this dynamic landscape.

Sustainability in Plastic Injection Molding: Trends and Future Directions

Sustainability in plastic injection molding has become a crucial concern as industries seek to reduce their environmental impact while maintaining efficiency and profitability. Recent trends indicate a significant shift towards the use of recycled materials, with many manufacturers exploring bio-based plastics as viable alternatives. These advancements not only address plastic pollution but also align with corporate responsibility initiatives. Companies are increasingly investing in research and development to enhance the recyclability of their products, thus fostering a circular economy where materials are reused rather than discarded.

Moreover, innovative technologies such as energy-efficient machines and waste reduction systems are gaining traction within the sector. The integration of automation and smart manufacturing is enabling companies to fine-tune their processes, leading to reduced energy consumption and minimized plastic waste. As consumers become more environmentally aware, the demand for sustainable practices in plastic injection molding is anticipated to grow, prompting manufacturers to adopt greener strategies. By embracing these trends, the industry can pave the way for a more sustainable future, simultaneously meeting market demands and preserving the planet.

Impact of Technology on Plastic Injection Molding Efficiency and Precision

The evolution of plastic injection molding is profoundly influenced by advancements in technology, significantly enhancing both efficiency and precision in manufacturing processes. With projections indicating that the global micro injection molding machine market will reach $759.2 million by 2032, industries are increasingly investing in cutting-edge solutions to improve their production capabilities. The introduction of AI-driven features in molding machines marks a significant leap forward, allowing for smarter operational strategies that optimize cycle times, reduce waste, and minimize costs.

Furthermore, innovative techniques such as low-pressure injection molding are emerging as vital components in sustainable manufacturing practices. As companies strive to align with environmental goals, the demand for processes that minimize energy consumption and material waste is rising. This method not only enhances the quality of molded products but also supports a shift toward eco-friendly practices that resonate with today’s conscientious consumers. In parallel, the integration of recycled materials in metal injection molding illustrates the industry's commitment to sustainability, balancing the necessity for high-precision components with the growing importance of reducing environmental impact.

Exploring Market Demand: Emerging Sectors for Plastic Injection Molding

As the plastic injection molding industry continues to evolve, emerging sectors are showcasing significant market demand. One notable sector is the automotive industry, where manufacturers increasingly rely on lightweight and durable plastic components to enhance fuel efficiency and reduce emissions. With electric vehicles on the rise, the demand for innovative parts created through injection molding is set to soar, promising new opportunities for manufacturers.

Another promising area is in consumer electronics, where rapid technological advancements are driving the need for complex and aesthetically pleasing components. Plastic injection molding offers a solution for producing intricate designs that cater to consumer preferences while maintaining cost-effectiveness. Industries producing smart devices, wearables, and home electronics are likely to see an uptick in injection molded products, making it a crucial sector for growth.

**Tips:** When venturing into these sectors, focus on sustainability by incorporating recycled materials into your injection molding processes. Additionally, stay up-to-date with technological advancements, as investing in automation and innovative techniques can enhance production efficiency and reduce waste. Emphasizing design flexibility will also allow your products to adapt to market trends, further tapping into these burgeoning industries.

Exploring Market Demand: Emerging Sectors for Plastic Injection Molding

| Sector | Market Size (in Billion $) | Growth Rate (%) | Key Applications |

|---|---|---|---|

| Automotive | 45 | 5.1 | Interior parts, exterior components |

| Consumer Goods | 60 | 4.5 | Household items, kitchenware |

| Healthcare | 35 | 7.2 | Medical devices, packaging |

| Electronics | 50 | 6.0 | Casing, components |

| Construction | 25 | 4.8 | Piping, insulation |

Challenges and Opportunities in the Plastic Injection Molding Industry

The plastic injection molding industry is poised for significant growth, projected to expand from USD 365.22 billion in 2024 to USD 580.44 billion by 2033, at a compound annual growth rate (CAGR) of 4.74%. This growth is fueled by increasing demand for plastic products across various sectors, including automotive, consumer goods, and healthcare. However, the industry faces challenges, such as environmental concerns regarding plastic waste and the need for more sustainable materials and processes.

As awareness of environmental issues rises, manufacturers are exploring innovative solutions to combat these challenges. Companies are investing in research and development to create biodegradable plastics and improve recycling processes. Additionally, advancements in injection molding technologies are enhancing efficiency and reducing energy consumption, paving the way for a more sustainable future. With these opportunities in mind, stakeholders in the plastic injection molding industry are strategically positioning themselves to navigate both the challenges and the growth potential the market presents.

Related Posts

-

Exploring Unique Product Features and Applications in Best Plastic Injection Mold Tooling

-

Common Challenges in the Best Plastic Injection Moulding Process

-

The Future of Precision Injection Molding Innovations and Trends

-

How to Optimize Your Injection Molding Tooling Processes for Maximum Efficiency

-

Exploring Innovative Alternatives in Plastic Engineering Solutions

-

7 Compelling Reasons to Choose Advanced Mold Manufacturing for Your Production Needs