The Future of Injection Molding Mold Technologies Driving Efficiency and Sustainability in Manufacturing

As industries increasingly prioritize efficiency and sustainability, the future of injection molding mold technologies emerges as a pivotal area for innovation. According to a recent report by the Allied Market Research, the global injection molding market is projected to reach $388.1 billion by 2027, growing at a CAGR of 4.9%. This growth is driven by advances in mold design and materials that reduce waste and energy consumption, aligning with manufacturers' goals to lower their carbon footprint. Notably, enhanced mold technologies are not only streamlining production processes but also enabling the use of recyclable and bio-based materials, significantly enhancing sustainability in manufacturing. As companies search for competitive advantages, adopting cutting-edge injection molding mold technologies will be essential for achieving operational efficiency while meeting the increasing demand for eco-friendly products.

Emerging Trends in Injection Molding Technologies for Sustainable Manufacturing

Emerging trends in injection molding technologies are revolutionizing the manufacturing landscape, prioritizing both efficiency and sustainability. Advances such as Industry 4.0 integration allow manufacturers to utilize smart machinery and IoT-based systems, which facilitate real-time monitoring and data analytics. These technologies optimize production processes by minimizing waste, enhancing energy efficiency, and improving overall product quality. For instance, adaptive control systems enable precise adjustments during the molding process, significantly reducing material consumption and cycle times.

Emerging trends in injection molding technologies are revolutionizing the manufacturing landscape, prioritizing both efficiency and sustainability. Advances such as Industry 4.0 integration allow manufacturers to utilize smart machinery and IoT-based systems, which facilitate real-time monitoring and data analytics. These technologies optimize production processes by minimizing waste, enhancing energy efficiency, and improving overall product quality. For instance, adaptive control systems enable precise adjustments during the molding process, significantly reducing material consumption and cycle times.

Moreover, the development of biodegradable and recycled materials is gaining traction in the injection molding industry. Manufacturers are increasingly adopting these sustainable materials, which not only meet performance standards but also reduce the environmental footprint of products. Innovations in mold design, including the use of additive manufacturing techniques, enable the creation of more complex geometries while maintaining resource efficiency. As a result, companies can respond more swiftly to market demands while contributing to a circular economy, signaling a significant shift towards sustainable manufacturing practices.

Integrating Digital Solutions to Enhance Mold Efficiency

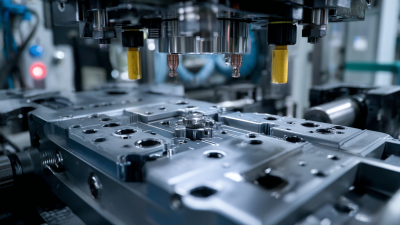

The integration of digital solutions in injection molding mold technologies is revolutionizing manufacturing efficiency and sustainability. According to a report by ResearchAndMarkets, the global injection molding market is expected to reach $300 billion by 2026, driven by advancements in mold efficiency and production processes. Digital tools such as advanced simulation software, IoT-enabled machinery, and real-time data analytics are becoming pivotal in reducing cycle times and improving production quality.

One significant advancement is the use of predictive maintenance driven by machine learning algorithms, which has been shown to decrease downtime by up to 30%. Additionally, by utilizing digital twins, manufacturers can test and optimize mold designs virtually before physical production, reducing material waste and accelerating time to market. In a study by Deloitte, companies that adopted digital solutions in their manufacturing processes reported a 20% improvement in operational efficiency, underscoring the importance of integrating technology to enhance mold performance and drive sustainable practices in injection molding.

Exploring the Role of Automation in Injection Molding Processes

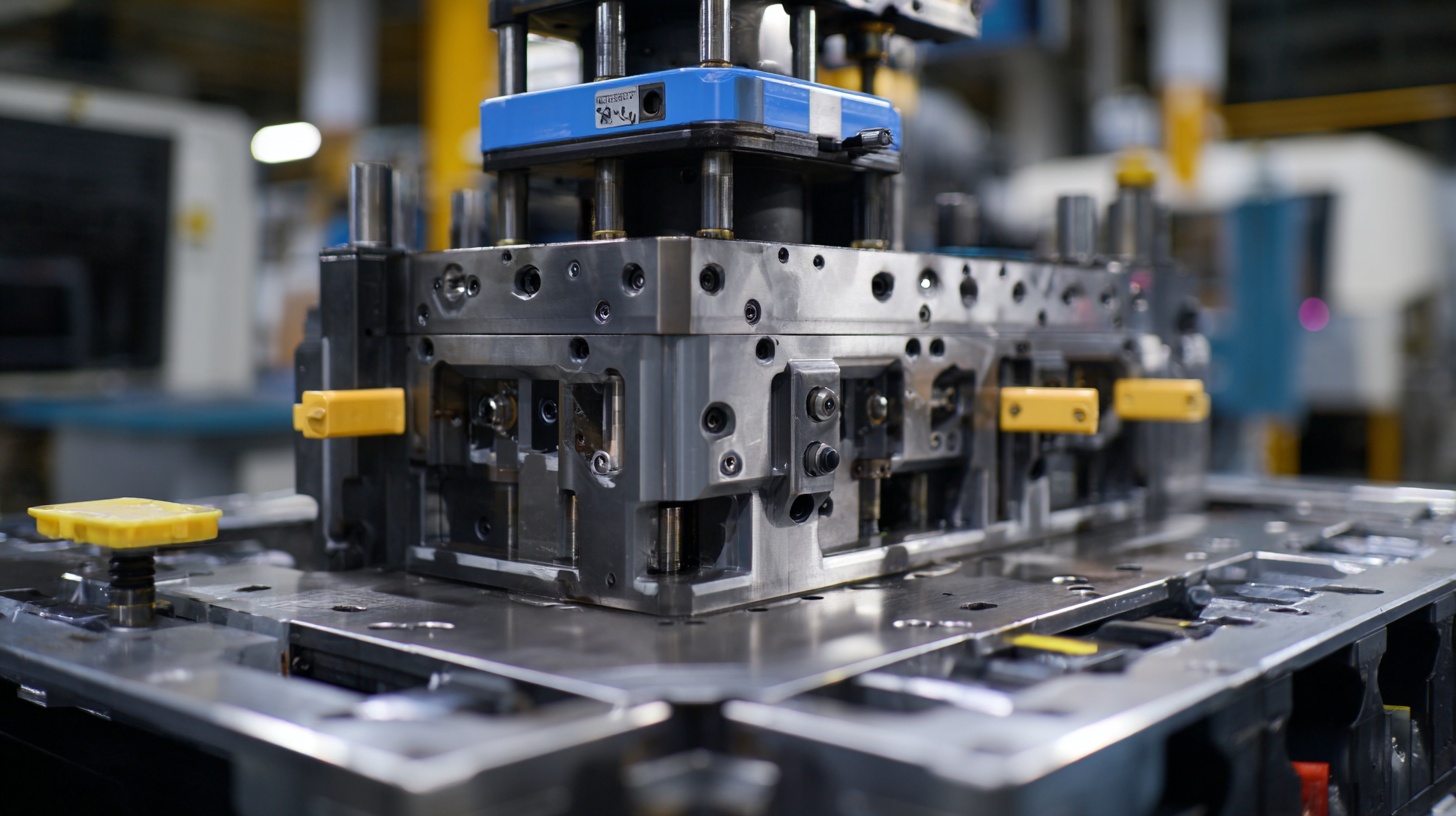

Automation is rapidly transforming the landscape of injection molding processes, enhancing both efficiency and sustainability in manufacturing. By integrating advanced robotic systems and smart technologies, manufacturers can produce high-quality components with minimal human intervention.

Automated systems streamline repetitive tasks such as material handling, part inspection, and machinery operation, significantly reducing cycle times and the likelihood of defects. This not only improves productivity but also lowers labor costs, allowing companies to allocate resources more effectively.

Automated systems streamline repetitive tasks such as material handling, part inspection, and machinery operation, significantly reducing cycle times and the likelihood of defects. This not only improves productivity but also lowers labor costs, allowing companies to allocate resources more effectively.

Furthermore, automation contributes to sustainability efforts by optimizing energy consumption and material usage within injection molding. Smart sensors and real-time monitoring allow for precise control over production parameters, reducing waste and ensuring that energy is only used when necessary. Additionally, automated systems can facilitate recycling initiatives by integrating processes that reuse scrap materials directly into the production line. As manufacturers increasingly embrace these automated technologies, the injection molding industry is poised to lead the way in sustainable manufacturing practices.

Sustainable Materials: The Future of Injection Molding

The injection molding industry is rapidly evolving, with a significant shift towards sustainable materials aimed at reducing environmental impact. According to a recent report by Grand View Research, the global sustainable materials market is expected to reach $600 billion by 2027, with a compound annual growth rate (CAGR) of over 9%. This growth is largely driven by the increasing demand for eco-friendly alternatives that not only minimize waste but also enhance the efficiency of manufacturing processes.

One of the key innovations in sustainable injection molding is the use of bio-based plastics, which are derived from renewable resources. A study by the Plastics Industry Association indicates that adopting bio-plastics can decrease carbon emissions by approximately 50-80% compared to traditional petroleum-based plastics. Moreover, advancements in recycling technologies are enabling manufacturers to incorporate recycled materials into their production cycles, further promoting sustainability. As companies strive to meet both regulatory requirements and consumer expectations for greener products, the integration of sustainable materials in injection molding processes is becoming a critical factor for success in the global marketplace.

The Future of Injection Molding: Efficiency and Sustainability in Manufacturing

This chart illustrates the sustainability scores of various injection molding materials. As manufacturers move towards sustainable practices, it is clear that biodegradable plastics outperform conventional materials. The adoption of recycled materials also shows promise in driving efficiency and sustainability in manufacturing processes.

Best Practices for Optimizing Mold Design and Production Efficiency

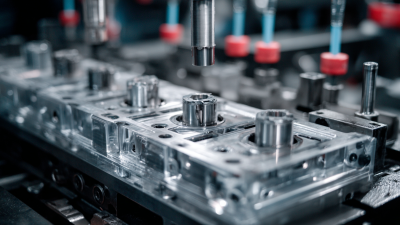

Optimizing mold design and production efficiency is critical for businesses aiming to enhance their competitiveness in the increasingly demanding manufacturing landscape. One best practice is incorporating advanced materials that offer improved durability and heat resistance, thereby reducing wear and tear during the injection molding process. By selecting the right materials, manufacturers can extend the lifespan of molds, leading to lower maintenance costs and increased production uptime.

Another key aspect involves leveraging simulation software during the design phase. By utilizing these tools, manufacturers can predict potential issues, such as shrinkage and flow patterns, allowing for precise adjustments before physical production begins. This not only shortens the development cycle but also mitigates costly errors. Additionally, regular training of engineering teams in the latest technologies and methodologies fosters a culture of continuous improvement, ultimately contributing to enhanced mold performance and efficiency.

The Future of Injection Molding Mold Technologies Driving Efficiency and Sustainability in Manufacturing - Best Practices for Optimizing Mold Design and Production Efficiency

| Technology | Efficiency Improvement (%) | Sustainability Factor | Production Speed (units/hour) | Best Practice |

|---|---|---|---|---|

| Digital Twin Technology | 30% | High | 200 | Real-time Monitoring |

| 3D Printing of Molds | 25% | Medium | 150 | Rapid Prototyping |

| Smart Sensors | 20% | High | 180 | Predictive Maintenance |

| Hybrid Molding | 15% | Medium | 220 | Material Efficiency |

| Eco-Friendly Materials | 10% | Very High | 160 | Material Selection |

Related Posts

-

How to Choose the Best Injection Molding Die for Your Production Needs: Insights from Industry Experts

-

The Future of Best Plastic Injection Mold Design: Innovations Driving Global Manufacturing Growth

-

Exploring Unique Product Features and Applications in Best Plastic Injection Mold Tooling

-

7 Essential Reasons Why Best Injection Moldable Plastics Are Your Ultimate Solution

-

Unlocking the Advantages of Best Injection Tooling in Modern Manufacturing Processes

-

Innovative Injection Molding Design Examples to Inspire Your Next Project