Exploring the Future of Mold Manufacturing with Advanced Automation Technologies

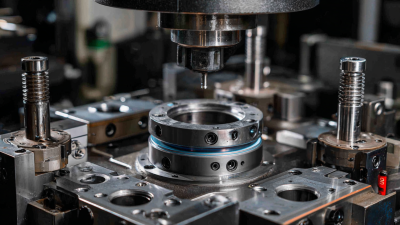

As the global mold manufacturing industry continues to evolve, the integration of advanced automation technologies is becoming increasingly critical for enhancing efficiency and precision. According to a recent report by MarketsandMarkets, the mold manufacturing market is projected to reach $18.9 billion by 2026, growing at a compound annual growth rate (CAGR) of 5.1% from 2021. This surge emphasizes the necessity for manufacturers to adopt cutting-edge solutions to stay competitive. Automation technologies such as robotic process automation (RPA) and artificial intelligence (AI) are transforming traditional practices, enabling shorter lead times, reduced labor costs, and improved accuracy in mold production. By exploring these innovations, mold manufacturers can optimize their operations, reduce waste, and ultimately enhance product quality, positioning themselves favorably in a rapidly changing market landscape.

As the global mold manufacturing industry continues to evolve, the integration of advanced automation technologies is becoming increasingly critical for enhancing efficiency and precision. According to a recent report by MarketsandMarkets, the mold manufacturing market is projected to reach $18.9 billion by 2026, growing at a compound annual growth rate (CAGR) of 5.1% from 2021. This surge emphasizes the necessity for manufacturers to adopt cutting-edge solutions to stay competitive. Automation technologies such as robotic process automation (RPA) and artificial intelligence (AI) are transforming traditional practices, enabling shorter lead times, reduced labor costs, and improved accuracy in mold production. By exploring these innovations, mold manufacturers can optimize their operations, reduce waste, and ultimately enhance product quality, positioning themselves favorably in a rapidly changing market landscape.

The Impact of Automation on Mold Manufacturing Efficiency and Productivity

The impact of automation on mold manufacturing efficiency and productivity is profound as advancements in technology redefine traditional processes. With the shift from manual labor to automated systems, companies are witnessing significant increases in production rates and quality. According to industry analysis, the global tooling market, comprising dies and molds, is projected to see substantial growth, driven by innovations that minimize waste and optimize resource use.

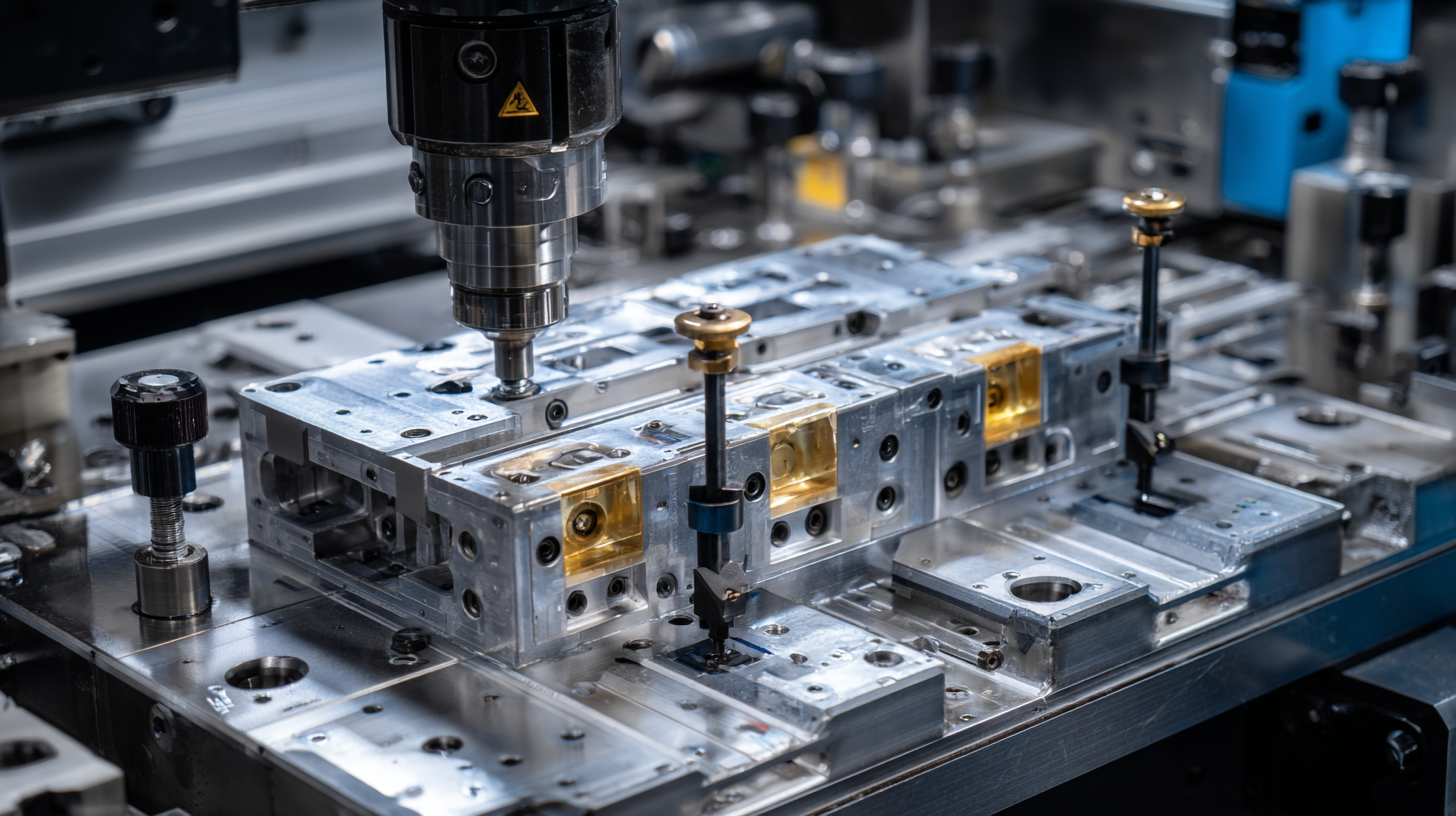

By implementing fully automated injection molding machines, manufacturers can streamline operations, resulting in reduced cycle times and enhanced precision. For instance, companies have reported up to a 30% increase in efficiency after embracing smart manufacturing technologies. Emphasizing sustainability, firms are also focusing on producing energy-efficient systems that align with environmental standards, thereby reducing their carbon footprint while meeting rising market demands.

**Tips:** To maximize the benefits of automation, assess your current processes and identify bottlenecks that can be streamlined. Additionally, invest in training your workforce to adapt to new technologies, ensuring that the transition to advanced manufacturing is smooth and beneficial for all stakeholders. Consider also collaborating with technology providers to customize automation solutions that meet your specific production needs.

Key Technologies Driving Automation in the Mold Manufacturing Sector

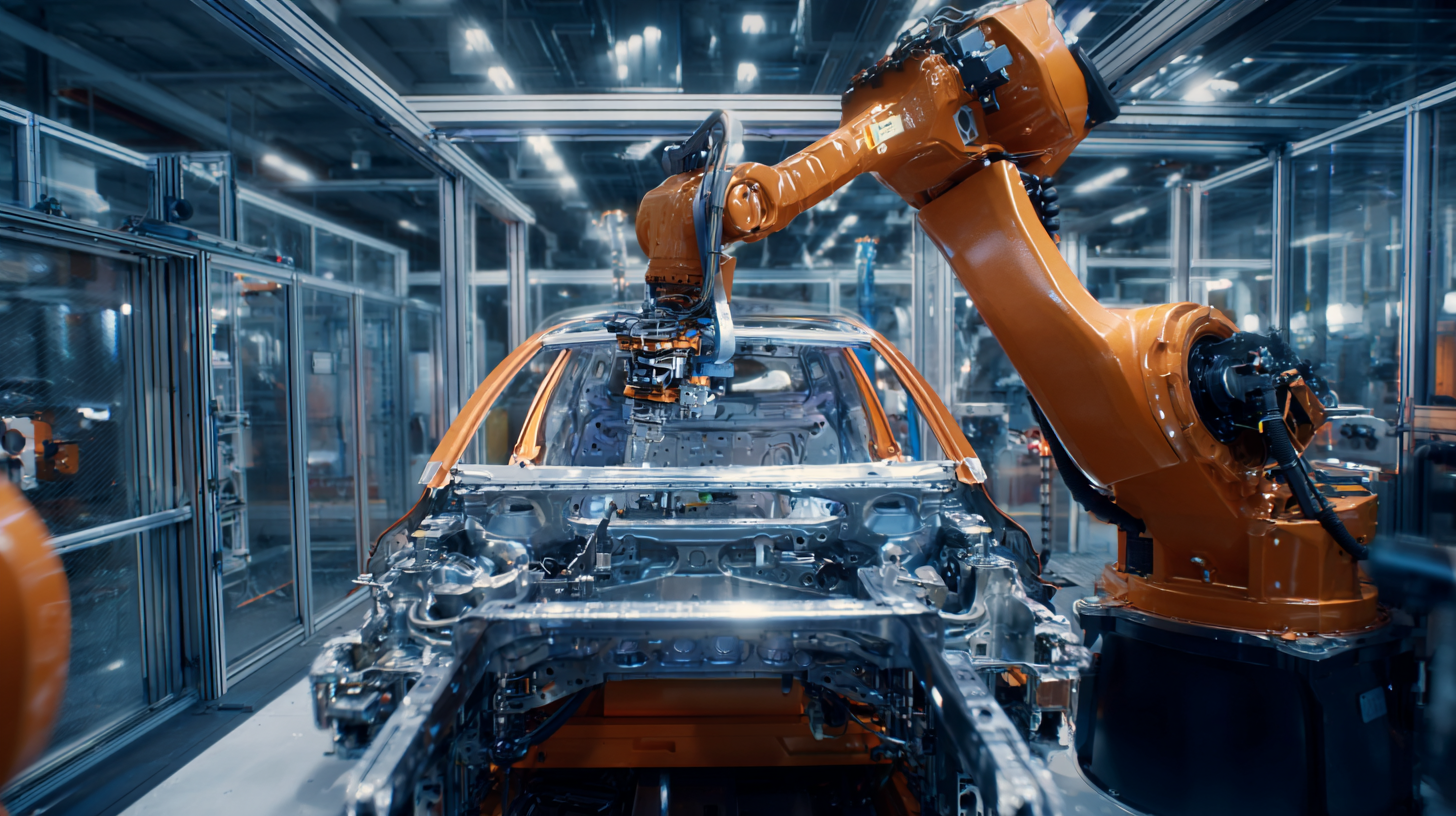

The future of mold manufacturing is undergoing a significant transformation, driven by advanced automation technologies that streamline operations and enhance productivity. Key technologies such as robotics, artificial intelligence, and IoT are leading the charge, enabling manufacturers to optimize processes and reduce downtime. Robotics, for instance, allows for precise machining and assembly, minimizing human error while speeding up production times. Artificial intelligence enhances decision-making capabilities, helping manufacturers predict maintenance needs and adjust operations in real-time.

Tips for integrating automation in mold manufacturing include starting with a thorough assessment of current processes to identify areas for improvement. Consider investing in modular automation solutions that can be easily scaled as production demands increase. Implementing IoT devices can further facilitate real-time data collection, leading to better insights and more informed decision-making.

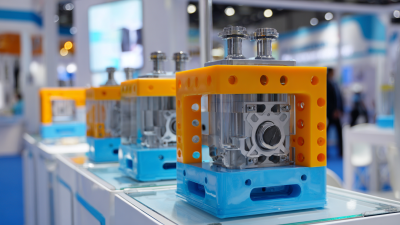

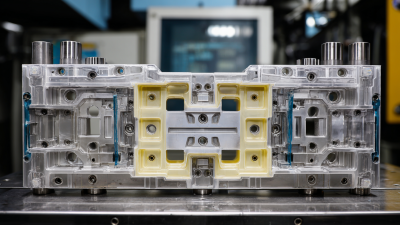

Another important technology is 3D printing, which aids in rapid prototyping and the production of complex mold designs. This not only shortens lead times but also enables customized solutions for clients. Embracing these technologies not only boosts efficiency but also positions mold manufacturers to meet the evolving needs of the industry.

Integrating AI and Robotics into Mold Design and Production Processes

The integration of AI and robotics into mold design and production processes is revolutionizing the industry by addressing the inefficiencies commonly associated with traditional methodologies. By employing intelligent data-driven design systems, manufacturers can leverage deep semantic understanding for enhanced decision-making capabilities. This approach not only reduces error rates but also streamlines complex design workflows, making it a pivotal advancement for modern mold creation.

Additionally, the advancements in robotics are enabling greater flexibility and autonomy in manufacturing environments. For instance, companies are increasingly deploying intelligent robots that can adapt to varying production demands, thereby optimizing the use of resources and time. This shift is complemented by AI technologies that facilitate predictive maintenance and real-time adjustments, ensuring that production remains efficient and responsive to market needs. As these technologies continue to evolve, they promise to reshape the future of mold manufacturing, fostering innovation and competitiveness in the sector.

Case Studies: Successful Implementation of Automation in Mold Manufacturing

The integration of advanced automation technologies in mold manufacturing has proven to be transformative, as evidenced by several successful case studies. One notable example is a leading automotive parts manufacturer that implemented robotic systems to enhance precision and reduce cycle times. By replacing manual processes with automated solutions, the company achieved a 30% increase in production efficiency while significantly reducing defects. This shift not only streamlined operations but also allowed the workforce to focus on higher-value tasks, thereby improving job satisfaction and skill development.

Another compelling case study involves a specialized mold maker that adopted AI-driven predictive maintenance tools. By leveraging data analytics, the company was able to anticipate equipment failures before they occurred, resulting in a remarkable 40% reduction in downtime. This proactive approach enabled the business to maintain continuous production and improve delivery times for clients, solidifying its competitive edge in a demanding market. These examples highlight the potential of automation in mold manufacturing to drive innovation, enhance productivity, and foster growth in an industry increasingly reliant on advanced technologies.

Future Trends: Predictions for Automation in the Mold Manufacturing Industry by 2030

The future of mold manufacturing is increasingly being shaped by advanced automation technologies. As we approach 2030, the mold manufacturing industry is expected to undergo significant transformations driven by efficiency, precision, and the integration of modern materials. According to recent analyses, the Chinese plastic mold industry is evolving towards greater efficiency, larger formats, and higher precision processes, catalyzed by a growing awareness of energy conservation and environmental sustainability. Emerging injection molding technologies are already setting new standards in production capabilities.

Furthermore, the trend of automation is pivotal, particularly highlighted in the latest reports forecasting substantial growth in the CNC machine tools market in China. The market size is expected to exceed 450 billion yuan by 2025, reflecting an increasing reliance on automated systems. This shift towards automation not only addresses existing challenges like labor shortages and supply chain disruptions but also optimizes production processes. As mold manufacturers invest in advanced CNC technologies and robotics, they stand to enhance productivity and accuracy, thus ensuring a competitive edge in the dynamic manufacturing landscape.

Exploring the Future of Mold Manufacturing with Advanced Automation Technologies

| Trend | Description | Projected Impact by 2030 | Technology Involved |

|---|---|---|---|

| Increased Automation | Integration of robotics and AI in the design and production processes. | Higher productivity and efficiency, with up to a 40% reduction in production time. | AI, Robotics |

| Smart Manufacturing | Utilization of IoT devices for real-time monitoring and analytics. | Enhanced decision-making leading to better resource management. | IoT, Big Data |

| Sustainable Practices | Adoption of eco-friendly materials and waste reduction techniques. | Significant decrease in environmental impact and cost savings. | Biodegradable materials, Recycling technology |

| Customization through 3D Printing | Leveraging 3D printing for rapid prototyping and custom molds. | Enhanced flexibility in design, reducing lead time for prototyping. | 3D Printing, CAD Software |

| Predictive Maintenance | Using machine learning algorithms to predict equipment failures. | Decreased downtime and maintenance costs by up to 30%. | Machine Learning, Predictive Analytics |

Related Posts

-

7 Compelling Reasons to Choose Advanced Mold Manufacturing for Your Production Needs

-

10 Reasons Precision Injection Molding Is the Best Choice for Your Business

-

How to Maximize Efficiency in Plastic Injection Molding: Strategies and Industry Insights

-

Innovative Injection Molding Design Trends to Watch at the 2025 Canton Fair

-

Unwavering Quality from Trusted Chinese Manufacturers in Best Plastic Mold Solutions

-

Unveiling the Science Behind Injection Molding: A Comprehensive Guide for Beginners