Revolutionizing Manufacturing: How Plastic Injection Molding Boosts Productivity by 30% in 2023

The manufacturing landscape is undergoing a significant transformation with the integration of advanced technologies, and plastic injection molding stands at the forefront of this revolution. According to a recent report by the American Society of Mechanical Engineers, businesses implementing plastic injection techniques have seen productivity gains of up to 30% in 2023. This impressive leap not only enhances efficiency but also reduces operational costs, positioning plastic injection as a critical player in modern manufacturing. As industries strive for greater agility and responsiveness in the face of market demands, the ability to produce high-quality plastic components quickly and economically has become paramount. With its automated processes and capability for mass production, plastic injection is reshaping traditional manufacturing paradigms, paving the way for innovations and driving sustainable growth across various sectors.

Benefits of Plastic Injection Molding for Modern Manufacturing Efficiency

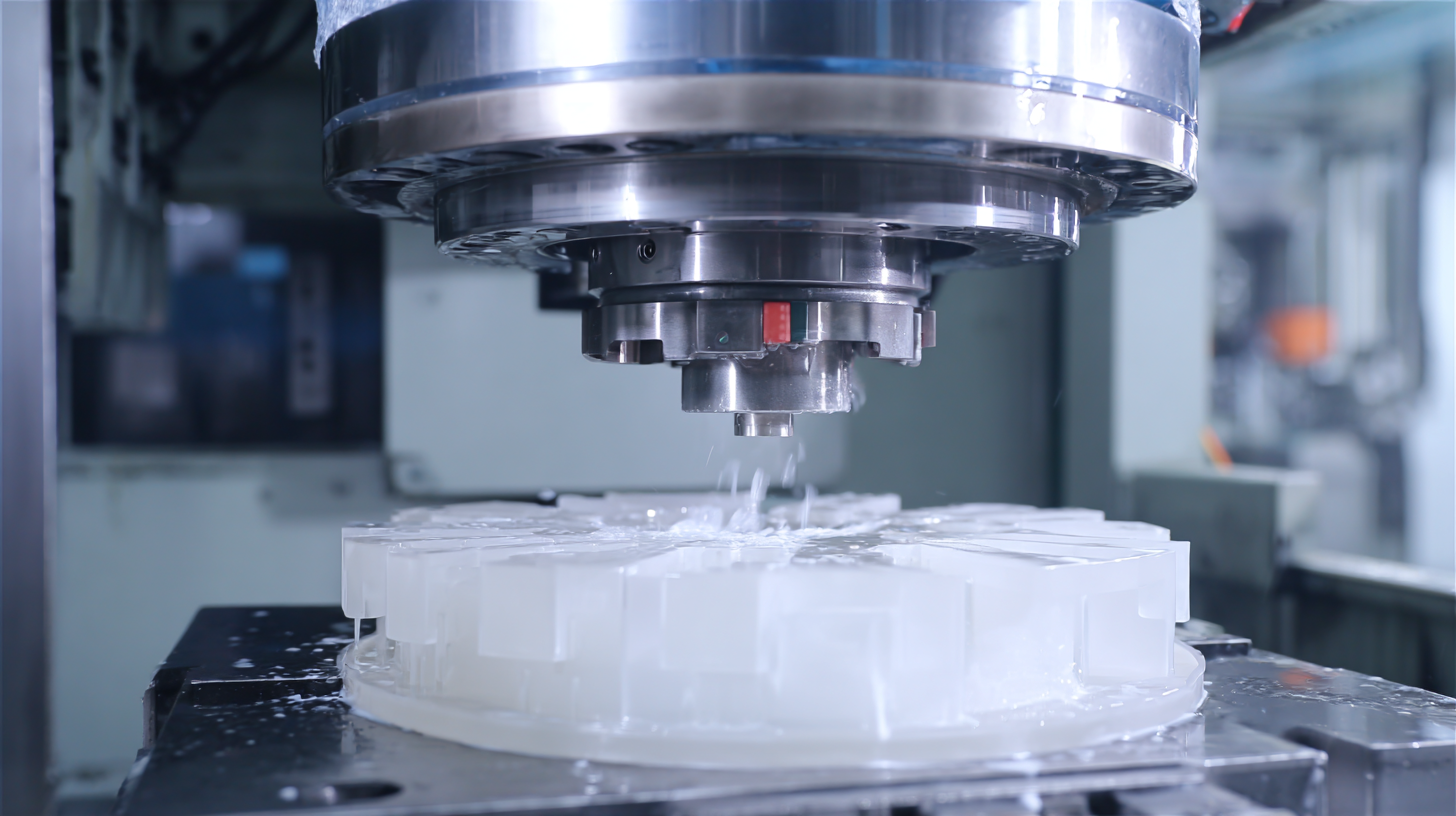

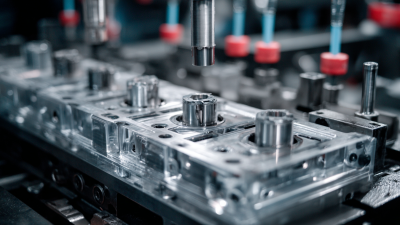

Plastic injection molding has emerged as a game-changer in modern manufacturing, significantly enhancing productivity and efficiency. According to a 2023 report by the Plastics Industry Association, companies utilizing plastic injection molding techniques have reported a productivity increase of up to 30%. This impressive figure is attributed to the method's ability to produce complex parts with high precision and at a rapid pace. The machinery used in this technique allows for faster cycle times, meaning that manufacturers can meet higher demands without compromising on quality.

Moreover, the benefits of plastic injection molding extend beyond just speed. It enables manufacturers to achieve greater material efficiency, resulting in reduced waste levels—often by as much as 20% compared to traditional manufacturing methods. This not only contributes to a more sustainable manufacturing process but also lowers costs. Additionally, advancements in technology have streamlined the design and production phases, allowing for rapid prototyping and a reduction in time-to-market. As industries continue to seek innovative solutions for efficiency, plastic injection molding stands out as a leading method that significantly transforms manufacturing operations.

Key Features of Injection Molding Machines That Enhance Productivity

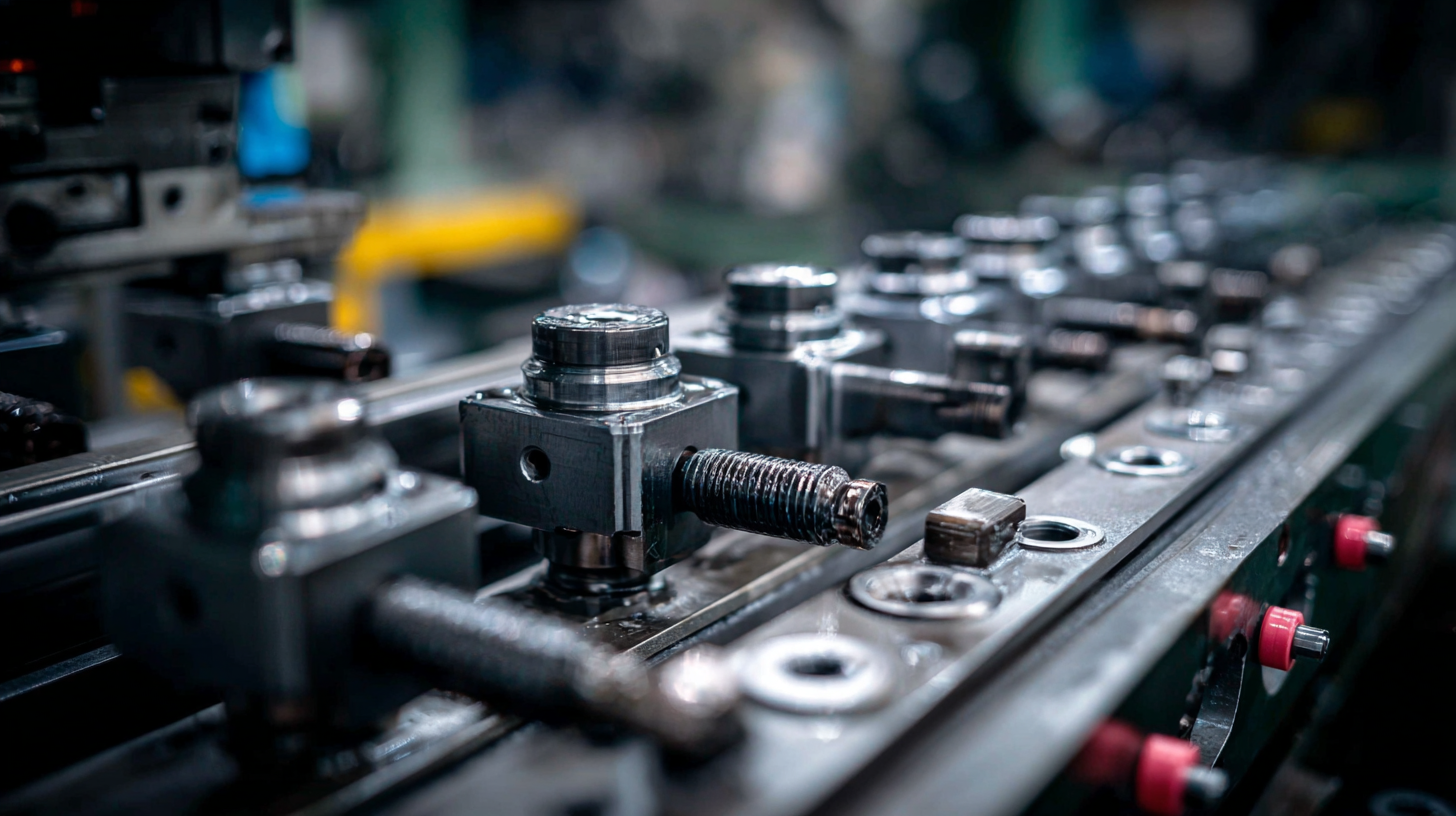

In 2023, the manufacturing sector is witnessing a significant transformation driven by advances in plastic injection molding technology. One of the key features enhancing productivity is the integration of intelligent production systems. These systems optimize operations by leveraging real-time data analytics, which can lead to a 30% increase in productivity. Additionally, modern injection molding machines incorporate energy-efficient designs, reducing overall energy consumption while maintaining high output levels. According to a recent industry report, the implementation of these technologies is projected to save manufacturers up to 20% on energy costs annually.

The opening of a new production plant in Querétaro, Mexico, illustrates the growing focus on expanding capabilities in the Americas to meet rising demands. This facility is expected to enhance local supply chains and improve service response times, which are crucial for industries relying heavily on just-in-time manufacturing. Furthermore, advancements in defect detection algorithms, such as the MRB-YOLO method, are pivotal for quality control. This new methodology utilizes an improved attention mechanism to enhance detection accuracy in injection molded parts, thereby reducing waste and improving product reliability. As these technological advancements continue to evolve, they are set to redefine manufacturing efficiencies and address the demands of an increasingly competitive market.

Impact of Plastic Injection Molding on Manufacturing Productivity (2023)

Innovative Materials in Plastic Injection Molding and Their Impact

Innovative materials play a crucial role in the field of plastic injection molding, significantly enhancing productivity and addressing environmental concerns. Among these advancements, Liquid Injection Molding (LIM) and Liquid Silicone Rubber (LSR) technologies are emerging as frontrunners. The market for LIM and LSR injection machines is expected to experience substantial growth, with a projected increase from $148.41 million in 2023 to $159.5 million by 2024. This growth reflects a shift towards more sustainable production methods, counteracting plastic waste through innovative recycling processes and material advancements.

The rise of sustainable alternatives, like linear low-density polyethylene (LLDPE), is transforming the plastic landscape, enabling manufacturers to meet increasing consumer demand while reducing environmental impact. As the global plastic contract manufacturing market expands, it underscores the importance of combining advanced technologies with eco-friendly materials. Manufacturers are increasingly outsourcing processes such as injection molding and extrusion to specialist providers, allowing for greater flexibility and efficiency. These innovative approaches not only boost productivity by 30% but also contribute to a circular economy, addressing the urgent issue of plastic pollution that has become a paramount environmental challenge.

Case Studies: Success Stories of Companies Utilizing Injection Molding

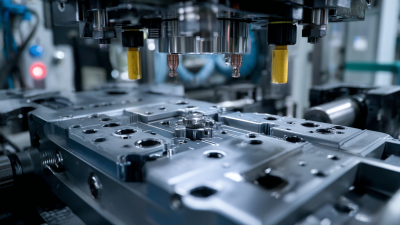

Injection molding has emerged as a game-changer in the manufacturing sector, with numerous case studies underscoring its impact on efficiency and productivity. For instance, a leading automotive parts manufacturer reported a staggering 35% reduction in production time after integrating advanced injection molding techniques.

According to a 2023 report by the Plastics Industry Association, companies utilizing injection molding saw an average productivity increase of 30%, primarily due to the rapid cycle times and reduced material wastage associated with the process.

Another success story comes from a consumer electronics firm that adopted injection molding to streamline its production of complex plastic components. The company experienced a significant drop in labor costs by 25%, as automated systems replaced time-consuming manual methods.

Industry data indicates that around 70% of all plastic parts are produced using injection molding, illustrating its dominance and effectiveness in various sectors. As demonstrated by these success stories, the strategic implementation of injection molding not only enhances productivity but also fosters innovation, enabling companies to remain competitive in a rapidly evolving marketplace.

Future Trends in Plastic Injection Molding and Their Importance for Industry

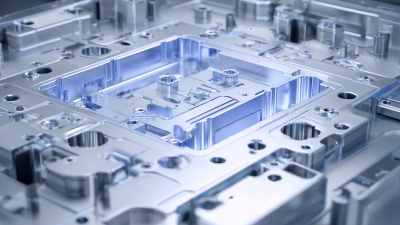

In 2023, the liquid injection molding (LIM) and liquid silicone rubber (LSR) injection machine markets are experiencing substantial growth, with a market value of approximately $148.41 million, projected to reach $159.5 million by 2024. This expansion reflects the increasing demand for high-performance polymer materials, which are essential in various industries due to their advanced properties such as high strength, excellent insulation, corrosion resistance, and eco-friendliness. The advancement of these materials is critical for national security and economic development, signifying a strategic shift towards more resilient manufacturing capabilities.

Future trends in plastic injection molding emphasize the significance of smart manufacturing techniques and automation. As global markets evolve, manufacturers are compelled to adapt to rising labor costs and unpredictable market demands. By leveraging technologies such as AI and data analytics, companies can enhance productivity and streamline operations, ultimately leading to a competitive edge in a rapidly changing industry landscape. The integration of intelligent manufacturing solutions is not only essential for operational efficiency but also crucial for maintaining market relevance in the face of increasing geopolitical risks and environmental regulations.

Related Posts

-

Exploring Unique Product Features and Applications in Best Plastic Injection Mold Tooling

-

Innovative Injection Molding Design Examples to Inspire Your Next Project

-

How to Optimize Your Injection Molding Tooling Processes for Maximum Efficiency

-

The Future of Best Plastic Injection Mold Design: Innovations Driving Global Manufacturing Growth

-

How to Maximize Efficiency in Plastic Injection Molding: Strategies and Industry Insights

-

10 Reasons Precision Injection Molding Is the Best Choice for Your Business