Unveiling the Science Behind Injection Molding: A Comprehensive Guide for Beginners

Injection molding is a pivotal manufacturing process employed across various industries, producing a vast array of products with unparalleled precision and efficiency. According to a report from Technavio, the global injection molding market is projected to reach $373.4 billion by 2026, growing at a CAGR of 5.1%. This impressive growth indicates the increasing reliance on injection molds for mass production in sectors such as automotive, consumer goods, and electronics. At its core, injection molding involves the use of molten material, typically thermoplastics, which is injected into a mold cavity to create specific shapes and designs. Understanding the intricacies of injection mold design and operation is essential for beginners looking to enter this dynamic field. This comprehensive guide aims to demystify the science behind injection molding, offering insights that will empower newcomers to harness its potential effectively.

Understanding Injection Molding: Key Concepts and Terminology for Beginners

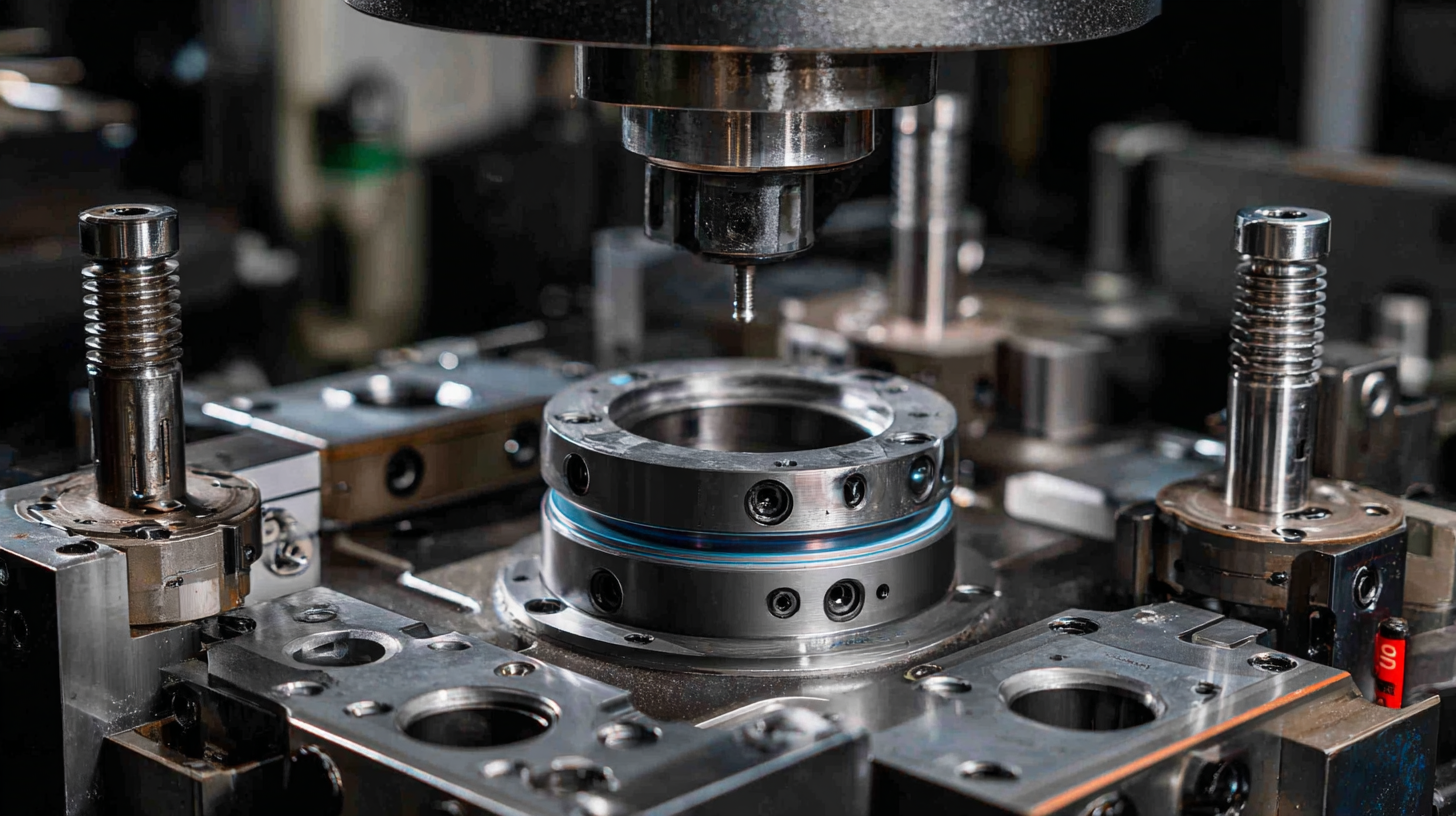

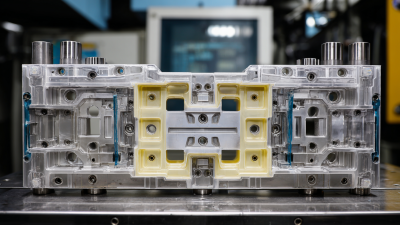

Injection molding is a manufacturing process widely used for producing parts by injecting molten material into a mold. For beginners, understanding key concepts and terminology is essential. Key terms include "mold," which is the hollow form that shapes the material, and "plasticization," which refers to the process of turning solid plastic pellets into a molten state before injection. The cycle time, which includes the injection and cooling phases, is also crucial in determining the efficiency of the molding process.

Tips for beginners: Always consider the type of material being used, as it affects the temperature and pressure required during injection. Additionally, familiarize yourself with different mold designs, as they can significantly impact the final product's quality. Engaging with online resources and seeking mentorship from experienced professionals can provide valuable insights and enhance your understanding of the injection molding process.

Another important concept is "clamping force," which holds the mold closed during injection. An insufficient clamping force can lead to defects like flash, which is excess material that seeps out of the mold. Beginners should prioritize learning about various machine settings to optimize production and reduce waste.

Understanding Injection Molding: Material Usage by Type

Essential Materials in Injection Molding: A Breakdown of Plastic Types and Their Properties

Injection molding is a widely used manufacturing process that relies heavily on various types of plastics, each possessing distinct properties that cater to specific applications. According to a report by MarketsandMarkets, the global injection molding plastic market is expected to reach USD 345.19 billion by 2025, with polypropylene (PP) and acrylonitrile butadiene styrene (ABS) being among the top polymers utilized. Polypropylene is lauded for its excellent fatigue resistance and low density, making it a popular choice for automotive components and consumer goods. Similarly, ABS is recognized for its toughness and impact resistance, which is essential in creating durable products like household appliances and electronic housings.

Injection molding is a widely used manufacturing process that relies heavily on various types of plastics, each possessing distinct properties that cater to specific applications. According to a report by MarketsandMarkets, the global injection molding plastic market is expected to reach USD 345.19 billion by 2025, with polypropylene (PP) and acrylonitrile butadiene styrene (ABS) being among the top polymers utilized. Polypropylene is lauded for its excellent fatigue resistance and low density, making it a popular choice for automotive components and consumer goods. Similarly, ABS is recognized for its toughness and impact resistance, which is essential in creating durable products like household appliances and electronic housings.

In addition to PP and ABS, polycarbonate (PC) is another crucial material in injection molding. Esteemed for its high strength and transparency, PC outperforms many other plastics in terms of toughness and heat resistance. The American Plastics Council indicates that PC's use in industries such as telecommunications and optics is projected to surge, driven by its ability to withstand harsh environments while maintaining clarity. Understanding these materials and their properties is vital for beginners in the injection molding industry, as selecting the appropriate plastic can greatly influence the overall performance and durability of the final product.

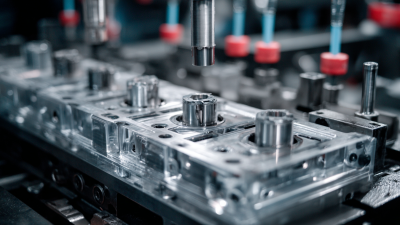

Optimal Process Parameters: How Temperature and Pressure Affect Mold Quality

Injection molding is a complex process that heavily relies on specific optimal parameters, particularly temperature and pressure, to achieve high-quality mold production. Research from the Society of Plastics Engineers shows that controlling the temperature within the mold is critical, as it influences the viscosity of the plastic being injected. For instance, a temperature that is too low can result in incomplete filling of the mold, while excessive temperatures can lead to thermal degradation of the material. Studies indicate that maintaining a melt temperature between 180°C to 220°C is often ideal for thermoplastics, striking a balance that ensures both flowability and physical integrity.

Moreover, pressure plays a significant role in determining the success of the injection molding process. According to a report by the American Society of Mechanical Engineers, injection pressures typically range from 700 to 2500 psi depending on the size and complexity of the part being produced. Adequate pressure helps to ensure that the molten material fills the mold completely and evenly, which is crucial for minimizing defects such as air traps or sink marks. Monitoring and adjusting these parameters can lead to significant improvements in mold quality and overall production efficiency, showcasing the intricate relationship between temperature, pressure, and the final product's characteristics.

The Role of Design in Injection Molding: Best Practices for Efficient Product Development

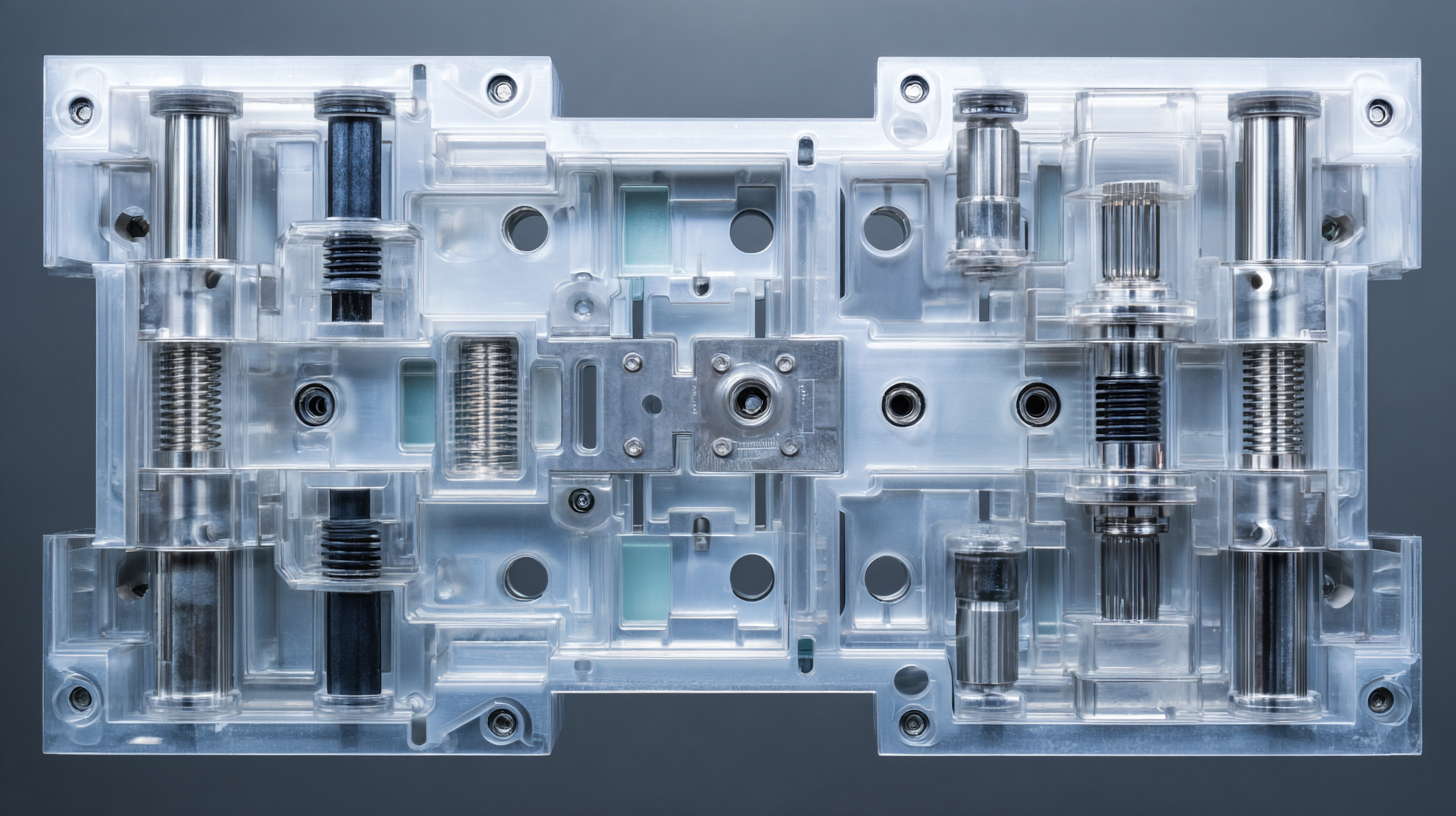

The design phase in injection molding is critical as it directly influences the efficiency and quality of product development. According to a report by the Plastics Industry Association, over 30% of production issues arise from poor design choices. Implementing best practices during design can significantly minimize these risks. For instance, incorporating features like draft angles, fillets, and uniform wall thickness can improve material flow and reduce stress concentrations, leading to fewer defects. A well-thought-out design can also optimize cycle times, with studies indicating that effective design can shorten the mold cycle by up to 20%.

Furthermore, the initial design phase should consider not just the aesthetics, but also manufacturability and assembly. The American Society for Testing and Materials (ASTM) emphasizes that designs that facilitate easy part removal and assembly result in up to 15% cost savings during production. By utilizing computer-aided design (CAD) and simulation software, engineers can foresee potential manufacturing challenges and address them proactively. This forward-thinking approach ensures that the final product meets both design specifications and performance requirements, making it a cornerstone of effective injection molding practices.

Unveiling the Science Behind Injection Molding: A Comprehensive Guide for Beginners

| Dimension | Description | Best Practices |

|---|---|---|

| Material Selection | Choosing the right plastic material based on product requirements and environmental factors. | Conduct thorough material testing; consider mechanical and thermal properties. |

| Part Design | Creating a design that maximizes efficiency and minimizes waste in production. | Follow design guidelines; use draft angles and avoid undercuts. |

| Mold Design | Crafting the mold with precision to ensure quality and ease of use. | Utilize flow analysis; design with cooling channels for better heat management. |

| Process Parameters | Setting optimal injection speed, temperature, and pressure to achieve the best results. | Regularly monitor and adjust parameters based on testing outcomes. |

| Production Efficiency | Maximizing output while minimizing material use and cycle time. | Implement lean manufacturing principles; automate wherever possible. |

Cost Considerations in Injection Molding: Analyzing Production Expenses and Time Efficiency

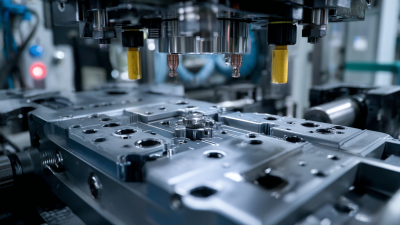

Injection molding is a widely utilized manufacturing process due to its ability to produce complex shapes efficiently. However, cost considerations play a critical role in its implementation. Key factors influencing production expenses include material costs, labor, machine maintenance, and energy consumption. Recent advancements in technology aim to optimize these elements, thereby leading to significant reductions in the overall cost of injection molding processes.

For instance, the integration of advanced management platforms enables real-time data monitoring and performance analysis, which can enhance efficiency by identifying areas for improvement. Additionally, innovations in machine design and predictive maintenance strategies are pivotal in minimizing downtime and maximizing productivity. As manufacturers seek to balance quality and cost, these technological improvements not only streamline operations but also contribute to sustainable practices in the industry. By prioritizing these considerations, companies can achieve better economic outcomes while maintaining the integrity and quality of their products.

Related Posts

-

The Future of Best Plastic Injection Mold Design: Innovations Driving Global Manufacturing Growth

-

Exploring Unique Product Features and Applications in Best Plastic Injection Mold Tooling

-

Unlocking the Advantages of Best Injection Tooling in Modern Manufacturing Processes

-

Unwavering Quality from Trusted Chinese Manufacturers in Best Plastic Mold Solutions

-

How to Optimize Your Injection Molding Tooling Processes for Maximum Efficiency

-

Unlocking Efficiency: Benefits of Injection Molding Die in Modern Manufacturing