Unlocking the Advantages of Best Injection Tooling in Modern Manufacturing Processes

In today's competitive manufacturing landscape, the use of advanced injection tooling has emerged as a critical factor in optimizing production efficiency and reducing costs. According to a recent study by MarketsandMarkets, the global injection molding market is projected to reach $322.1 billion by 2025, reflecting a compound annual growth rate (CAGR) of 3.5% from 2020. This growth highlights the increasing importance of injection tooling in modern manufacturing processes. One of the key advantages of high-quality injection tooling lies in its potential to significantly lower maintenance costs while enhancing after-sales service.

As manufacturers seek to improve product quality and accelerate time-to-market, understanding the operational benefits and cost-saving opportunities associated with superior injection tooling becomes essential. This blog will explore how effective injection tooling strategies can unlock substantial advantages for manufacturers, particularly in terms of after-sales support and maintenance expenses, while providing actionable insights on implementation.

The Evolution of Injection Tooling: From Traditional to Digital Approaches

The evolution of injection tooling has marked a significant shift in manufacturing processes, transitioning from traditional methods to advanced digital approaches. According to a report by the Boston Consulting Group, companies that integrate digital technologies into their production processes can improve efficiency by up to 30%. This shift not only enhances the precision of tooling but also decreases lead times, allowing manufacturers to respond more quickly to market demands.

Additionally, the use of computer-aided design (CAD) and computer-aided manufacturing (CAM) has revolutionized the injection tooling landscape. A study published in the Journal of Manufacturing Science and Engineering indicates that the implementation of these technologies has led to a 40% reduction in prototyping time. As manufacturers embrace these digital tools, they can achieve greater customization in their product designs while ensuring consistent quality. The trend towards automation and data analytics further bolsters this transformation, paving the way for smarter manufacturing solutions that address the challenges of modern production environments.

Unlocking the Advantages of Best Injection Tooling in Modern Manufacturing Processes

Key Features of Best Injection Tooling in Enhancing Efficiency

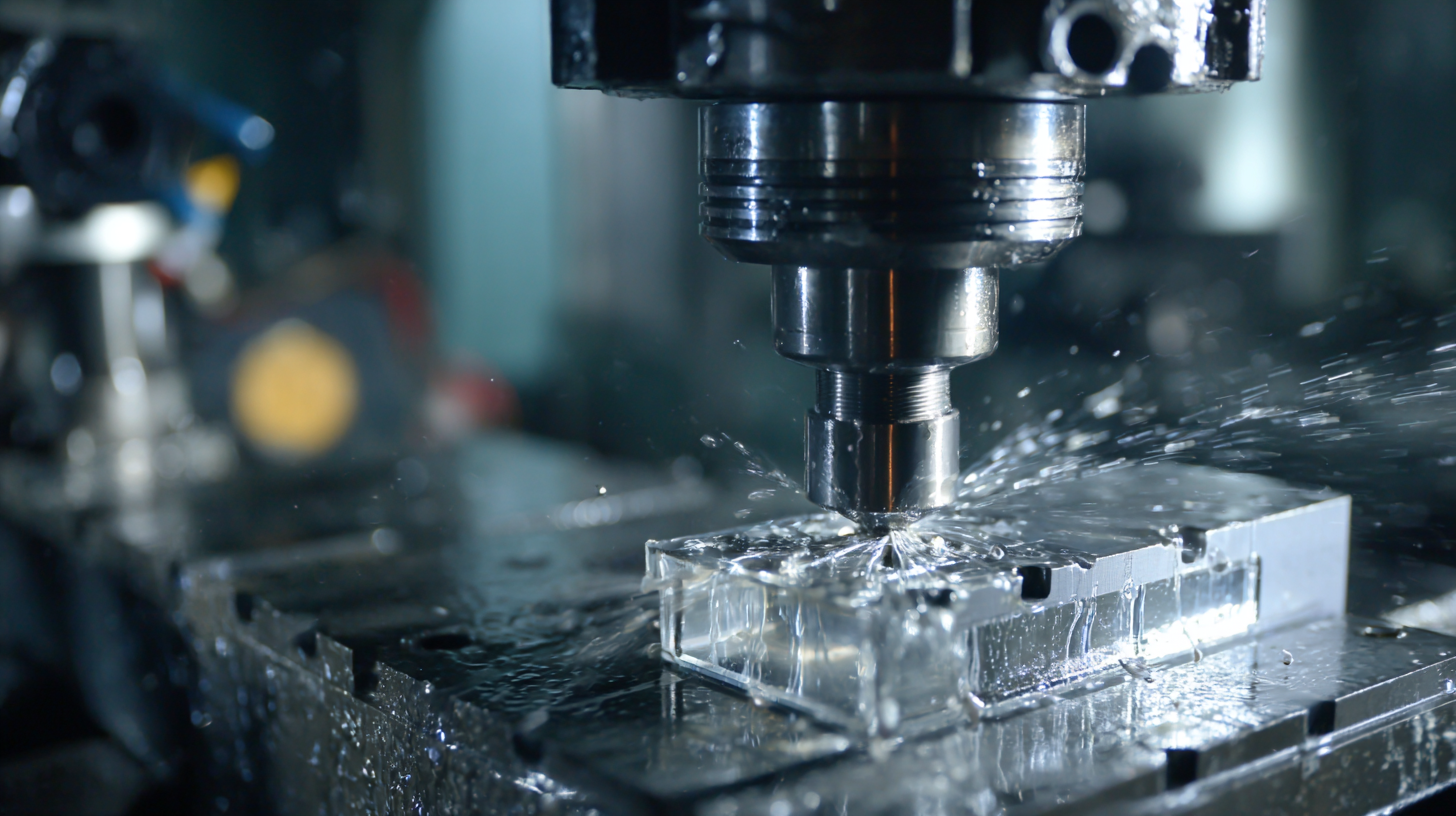

In modern manufacturing processes, the adoption of the best injection tooling is crucial for enhancing efficiency and productivity. One of the standout features of high-quality injection tooling is its precision. Tools that are meticulously designed and engineered can significantly minimize errors during production, resulting in a higher yield of flawless components. This precision not only saves time but also reduces material waste, thereby making the entire manufacturing process more sustainable.

Another key feature is the speed of the injection tooling systems. Innovative designs incorporate automated processes and faster cycle times, which allow manufacturers to increase output without compromising on quality. By investing in advanced tooling solutions, companies can respond more rapidly to market demands and produce goods in a fraction of the time compared to traditional methods.

**Tip:** When selecting injection tooling, consider investing in modular systems that facilitate easy upgrades. This adaptability allows manufacturers to scale production and adapt to new product lines without extensive downtime.

**Tip:** Regular maintenance of injection molds and tooling is essential to ensure longevity and optimal performance. Implementing a routine check can help identify potential issues early and prevent costly repairs in the long run.

Integrating Digital Technologies for Precision in Injection Tooling

In modern manufacturing processes, the integration of digital technologies into injection tooling is proving to be a game-changer. Advanced software tools, such as CAD and CAM, enhance the design and production of injection molds, allowing for precision engineering that significantly reduces cycle times. According to a report by MarketsandMarkets, the global injection molding market is expected to reach $300 billion by 2025, growing at a CAGR of 4.8%. This growth is largely driven by the push for increased efficiency and lower operational costs, which digital technologies can provide.

Furthermore, the utilization of additive manufacturing within injection tooling processes enables rapid prototyping and customization, allowing manufacturers to produce tools that meet the specific demands of their clients. A study conducted by Deloitte highlights that companies implementing digital tools in their production processes can achieve up to a 20% increase in productivity. By leveraging technologies such as IoT and AI for real-time monitoring and predictive maintenance, manufacturers can also enhance the longevity and performance of their tooling equipment, minimizing downtime and maximizing output. The future of injection tooling looks bright as digital integration continues to elevate manufacturing capabilities.

Benefits of Advanced Materials in Modern Injection Tooling Applications

In the realm of modern injection tooling applications, advanced materials play a pivotal role in enhancing efficiency and durability. Utilizing materials like carbon fiber and high-performance polymers not only increases the lifespan of molds but also minimizes production costs. The incorporation of these advanced materials allows for lighter designs that can withstand higher temperatures and pressures, thus optimizing the overall manufacturing process.

Tip: When selecting materials for injection tooling, consider the specific requirements of your project, such as thermal stability and chemical resistance. This will ensure that the tooling performs effectively while maintaining quality standards.

Furthermore, the shift towards more sustainable practices in manufacturing has made advanced materials essential. Many of these materials are designed to reduce waste and energy consumption, contributing to a greener production process. Adopting these materials can also lead to innovations in design, enabling manufacturers to create more complex geometries that were previously unachievable.

Tip: Keep an eye on emerging material technologies, as they can offer significant competitive advantages. Regularly updating your tooling materials can not only improve product quality but also enhance your production capabilities.

Unlocking the Advantages of Best Injection Tooling in Modern Manufacturing Processes - Benefits of Advanced Materials in Modern Injection Tooling Applications

| Aspect | Details | Benefits |

|---|---|---|

| Material Type | Thermoplastics | High durability and versatility |

| Injection Speed | Fast cycle times | Increased productivity |

| Precision | High dimensional accuracy | Reduced waste and rework |

| Customization | Tailored designs for specific applications | Enhanced product performance |

| Sustainability | Use of recycled materials | Lower environmental impact |

| Control Systems | Advanced automation and monitoring | Improved process consistency |

Case Studies: Success Stories of Best Injection Tooling in Manufacturing

In modern manufacturing, the adoption of advanced injection tooling techniques has led to remarkable success stories across various industries. For instance, a study by the Association for Manufacturing Technology indicates that manufacturers utilizing cutting-edge injection molding technologies have witnessed a 25% increase in production efficiency and a 30% reduction in cycle times. Companies that have modernized their tooling processes report not only enhanced product quality but also a significant decrease in material waste, contributing to more sustainable manufacturing practices.

One notable case is that of a leading automotive parts supplier, which implemented state-of-the-art injection tooling systems and experienced an impressive 40% improvement in their output capacity. By integrating smart technologies such as IoT sensors, they were able to monitor production in real-time, leading to a 15% decrease in downtime. This not only boosted their productivity but also lowered operational costs considerably, highlighting the pivotal role of best injection tooling in driving success in the competitive landscape of manufacturing.