Best Ball Screw for Sale Options in 2026 What to Know?

In 2026, the market for ball screws is evolving rapidly. Buyers are faced with numerous options for ball screw for sale. Each option comes with distinct advantages and challenges.

Choosing the right ball screw can be overwhelming. Factors like load capacity, precision, and material quality play roles. Each aspect can significantly affect performance. Some buyers might overlook the importance of compatibility with existing systems. This oversight can lead to costly mistakes.

Researching brands and suppliers is crucial. Reliable manufacturers often provide detailed specifications and customer support. Buyers should also consider long-term maintenance and durability. It's easy to focus solely on initial costs, but longevity matters more. Reflecting on these details can lead to better purchasing decisions. The right ball screw can enhance efficiency and productivity in various applications.

Best Ball Screw Types Available for Sale in 2026

In 2026, the demand for ball screws is projected to grow significantly. Data from industry reports indicates an increase of approximately 8% in the ball screw market annually. Several types of ball screws will dominate this market, each catering to different applications and preferences.

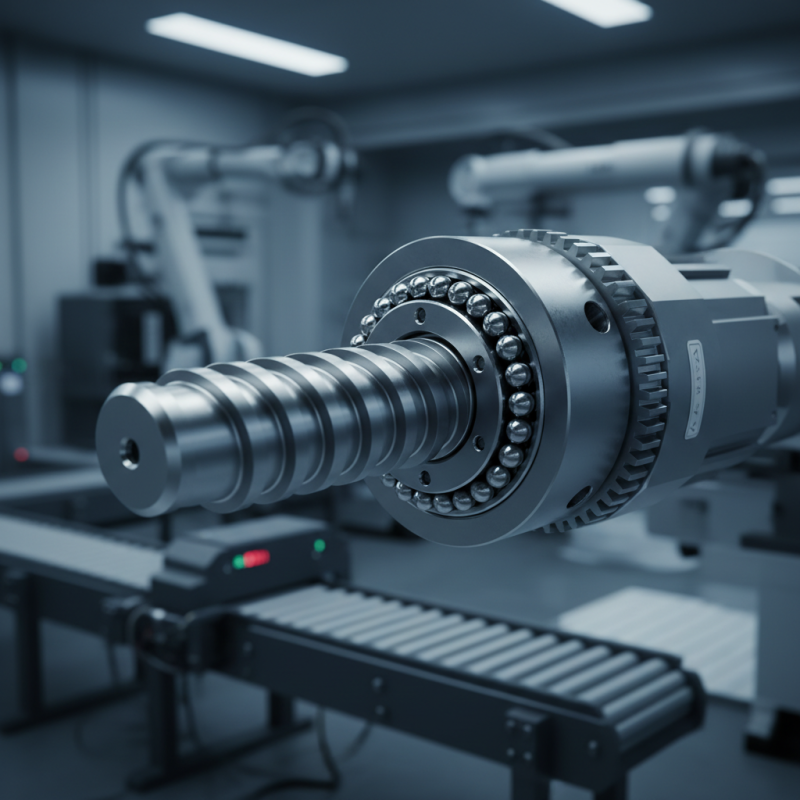

Precision ball screws are ideal for applications needing high accuracy. They have minimal backlash and are commonly used in CNC machines. Conversely, high-load ball screws are designed for heavy-duty applications. These offer better durability, making them perfect for industrial machinery. Another emerging trend is the use of compact ball screws, which are increasingly favored in robotics and automation. They take up less space while providing the same performance.

**Tip:** When selecting a ball screw, consider the load and speed requirements. Misjudging these factors could lead to inefficiency.

It's important to note that many producers still face challenges regarding material quality. Some screws may not meet the desired performance standards. A reflection on supplier selection can help mitigate risks related to quality assurance.

**Tip:** Always request samples for testing before making bulk purchases. This practice can save time and resources in the long run.

Key Features to Consider When Choosing Ball Screws

When selecting the best ball screws in 2026, several key features require careful consideration. Precision is paramount. A ball screw with higher accuracy delivers smoother motion and better performance. It can be the difference between success and failure in critical applications. Look for the lead accuracy and repeatability metrics. These details directly impact your project's outcomes.

Load capacity is another essential factor. Consider how much weight the screw will handle. It should match your application needs. A screw rated higher than required may offer a safety buffer. However, over-specifying can increase costs unnecessarily. Think about the operating environment too. Some ball screws are better suited for harsh conditions, while others may corrode easily.

Another aspect that shouldn't be overlooked is lubrication type. The right lubricant affects lifespan and efficiency. It reduces friction, hence enhancing performance. Think about the maintenance needs as well. Low maintenance options might save time and costs in the long run, but they can lack flexibility. Finding the right balance requires some reflection and might not be straightforward.

Comparison of Leading Ball Screw Brands for 2026

When exploring ball screw options, it’s essential to focus on the leading brands for 2026. According to recent industry reports, the global ball screw market is expected to grow at a CAGR of 7.3% from 2023 to 2028. Such data reflects a rising demand in automation and machinery applications. The right brand can significantly impact performance and longevity.

Leading brands typically focus on precision and load capacity. For instance, ball screws with higher accuracy ratings can enhance machinery efficiency. Many users report mixed experiences with brands, citing issues with durability under high loads. There’s a notable difference in manufacturing quality across different companies. Some ball screws may wear out faster than anticipated, causing delays in production.

In terms of cost, price variations can be significant among leading brands. Companies need to weigh the initial investment against long-term benefits. A cheaper option might seem appealing but could lead to higher maintenance costs. With increasing automation, the importance of selecting the correct ball screw cannot be overstated. Careful consideration of brand specifications may help avoid future operational hurdles.

Pricing Trends and Cost-Effective Options for Ball Screws

When considering ball screws for sale in 2026, understanding pricing trends is crucial. The market has seen fluctuations due to material costs and supply chain issues. Prices may rise as production expenses increase. It's essential to monitor these trends closely. Unsurprisingly, affordable options are often available, but they do come with trade-offs. Quality and reliability might vary significantly.

Cost-effective ball screws play an essential role for many manufacturers. Choosing lower-priced options may save money upfront. However, they can lead to higher maintenance costs later. Skills in balancing cost with performance will be vital for buyers. Investigation into alternative materials can offer additional savings too.

While some budget-friendly choices exist, one must consider long-term implications. Make sure the selected ball screw meets your specific needs. Research and comparison are your best tools. In this evolving market, being informed is key. Don't overlook the importance of quality in your purchase decision.

Maintenance Tips for Longevity of Ball Screws in Various Applications

Maintaining ball screws is vital for their longevity. These components require regular attention, especially in dynamic environments. Ensure that lubrication is adequate. Use the right type of grease or oil, and apply it consistently. Inadequate lubrication can lead to wear and tear. Check for signs of overheating or unusual noise frequently.

Contamination is another common issue. Dirt and debris can cause damage over time. Keep the environment clean where ball screws operate. Consider using protective covers or seals. This simple step can significantly extend the life of the screws. Furthermore, performing routine inspections is essential. Look for misalignment and wear on the balls and grooves. Small issues can escalate if not addressed promptly.

Some users overlook the impact of operational loads. Exceeding the weight or speed ratings can lead to premature failure. Analyzing load conditions helps in making informed decisions. Adjusting application parameters might be necessary. Learning from past experiences is crucial. Ignoring small problems can lead to bigger headaches later on.