15 Best Tips for Mastering the Injection Moulding Process?

The injection moulding process is a vital technique in manufacturing. It shapes plastic materials into desired forms, which are used widely. However, mastering this process can be challenging. Many factors influence quality and efficiency.

Understanding the injection moulding process requires attention to detail. Temperature, pressure, and timing all play crucial roles. Small errors can lead to defects and wasted resources. This highlights the importance of continuous learning and improvement.

There are tips and strategies that can help refine your approach. Experimenting with different settings and materials is key. Reflection on each project can lead to better outcomes. Embracing mistakes can foster innovation. The journey of mastering the injection moulding process is ongoing.

Understanding the Basics of Injection Moulding Technology

Injection moulding is a technique used to create objects from thermoplastic and thermosetting polymers. This process begins with heating plastic until it becomes molten. The molten plastic is then injected into a mould. Once the plastic cools down, it solidifies into the final product. Understanding this basic mechanism is essential for anyone looking to master the injection moulding process.

One of the challenges in injection moulding is achieving uniform temperature. If the plastic is too cold, it may not fill the mould properly. Conversely, if it’s too hot, defects can occur. Monitoring the temperature is crucial. It can be frustrating when small issues lead to larger problems in production. Another common issue is achieving the right pressure. Inadequate pressure can produce weak products. Adjustments might be needed. After learning the basics, reflecting on these challenges is important to improve efficiency.

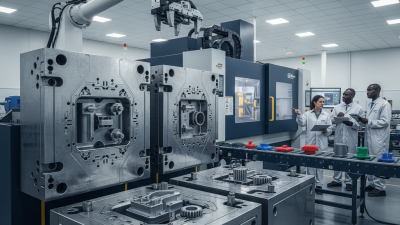

Essential Equipment and Tools for Effective Injection Moulding

The injection moulding process requires precise equipment to ensure efficiency and quality. A high-quality injection moulding machine is crucial. This machine provides the necessary pressure and temperature for melting plastic. Proper maintenance is essential; neglect can lead to defects.

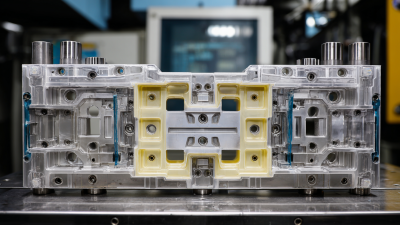

Moulds are another key component. They should be designed with careful consideration of the final product's specifications. Many overlook the importance of cooling channels in molds. Inadequate cooling can result in longer cycle times.

Additionally, auxiliary equipment plays a substantial role. For example, a hopper loader can simplify material handling. However, operators must monitor material flow to prevent clogs. Lastly, temperature controllers regulate the heating of materials. Setting the right temperatures is vital. Too high, and you risk degradation; too low, and it may not flow properly. Continuous learning and adaptation are necessary in this field.

15 Best Tips for Mastering the Injection Moulding Process

| Tip Number | Tip Description | Essential Equipment/Tools | Purpose |

|---|---|---|---|

| 1 | Choose the right material for your application | Material Selection Guide | Ensures optimal performance and durability |

| 2 | Optimize the injection speed | Injection Moulding Machine | Reduces defects and improves cycle time |

| 3 | Maintain consistent temperature settings | Temperature Control System | Enhances melt flow and part quality |

| 4 | Use effective mould design | Mould CAD Software | Improves part accuracy and minimizes waste |

| 5 | Perform regular equipment maintenance | Maintenance Tools Kit | Ensures reliable operation and longevity |

| 6 | Implement a quality control procedure | Quality Inspection Tools | Detect defects early and minimize rework |

| 7 | Control cooling times efficiently | Cooling System | Improves cycle times and part properties |

| 8 | Use simulation software for testing | Simulation Software | Predicts outcomes and optimizes design |

| 9 | Train staff on best practices | Training Programs | Enhances skill sets and enhances productivity |

| 10 | Evaluate the need for automation | Automated Systems | Reduces labor costs and increases efficiency |

| 11 | Implement waste reduction strategies | Waste Management Tools | Increases sustainability and reduces costs |

| 12 | Analyze production data regularly | Data Analysis Software | Informs decision-making and optimizes processes |

| 13 | Adjust injection pressure as needed | Pressure Control Systems | Improves product uniformity and reduces defects |

| 14 | Stay updated on industry advancements | Industry Publications | Enhances competitive edge and knowledge |

| 15 | Conduct regular financial analysis | Financial Analysis Tools | Ensures cost-effectiveness and profitability |

Key Parameters for Optimizing the Injection Moulding Process

Optimizing the injection moulding process requires a deep understanding of key parameters.

Temperature, pressure, and cooling time are critical elements. The barrel temperature should be carefully monitored.

Too high can degrade materials, while too low can lead to poor flow.

Temperatures between 200-250°C usually work well, but each material varies.

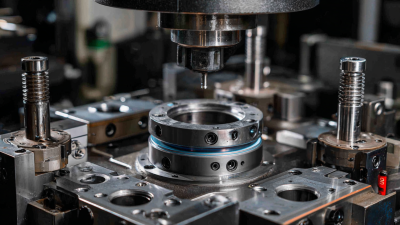

Pressure control is vital. High pressure can lead to defects like warping or sink marks.

Conversely, low pressure may result in incomplete filling. Calibration of injection pressure should be precise. Cooling time is another factor to consider.

If it's too short, parts won't solidify correctly. A cooling time of 20-30% of the cycle time is a common starting point, but adjustments are often needed.

Another challenge is the choice of the right material. Different polymers behave differently under similar conditions.

Material properties greatly impact the final product. Testing various materials can lead to better outcomes.

Even experienced operators may overlook small adjustments in these parameters that lead to defects. Regularly reviewing past production runs helps uncover these insights.

Each run presents learning opportunities to enhance the process continuously.

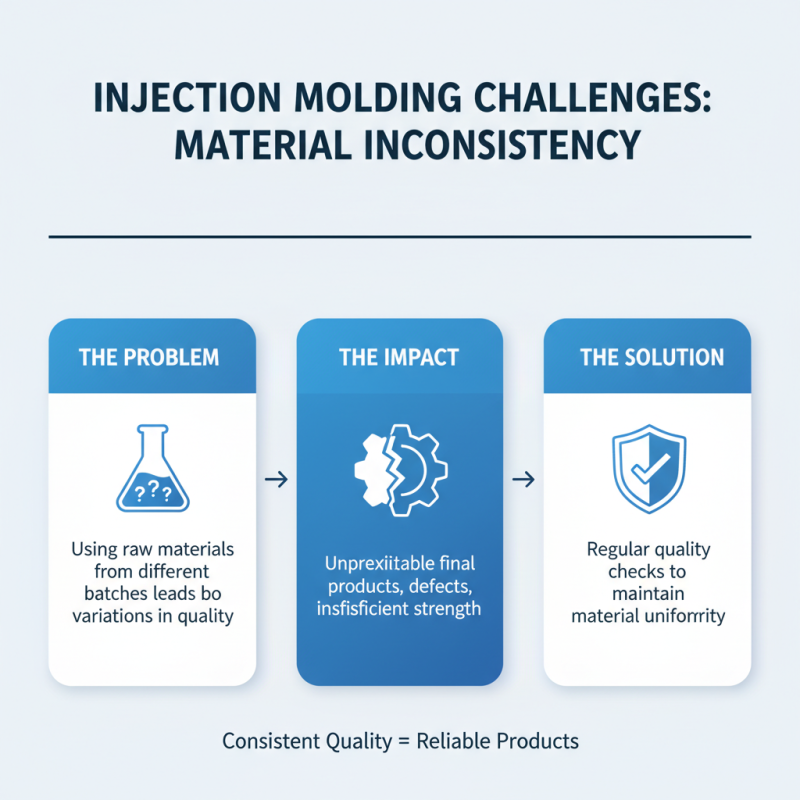

Common Challenges in Injection Moulding and How to Overcome Them

Injection moulding is an intricate process that can present numerous challenges. One common issue is material inconsistency. Using raw materials from different batches can lead to variations in quality. This unpredictability affects the final products, resulting in defects or insufficient strength. Regular quality checks are vital to maintain material uniformity.

Another significant challenge is temperature control. Maintaining the right temperature is crucial for ensuring proper material flow. If the temperature is too low, the material may not fill the mould adequately. Conversely, if it’s too high, it can lead to degradation. Operators need to monitor temperatures continuously, adjusting as necessary to avoid these pitfalls.

Additionally, cycle time optimization is often overlooked. Longer cycles can decrease overall productivity. However, rushing the process might compromise the quality. Finding the perfect balance is essential. Regular reviews of cycle times and making adjustments based on specific product requirements can help streamline production without sacrificing quality. Continuous reflection and adjustment are essential in mastering this complex process.

Best Practices for Quality Control in Injection Moulding Operations

Quality control is crucial in injection moulding operations. Ensuring that the final products meet specifications can greatly influence customer satisfaction. Start by conducting thorough inspections on raw materials. Defects in raw materials can lead to compromised parts. Regularly updating your quality checklists can help identify potential issues early.

Monitoring machine settings is another best practice. Small changes in temperature can impact the final product. Even a few degrees can cause warping or inconsistencies. Operators should be trained to recognize these deviations and adjust settings accordingly. It’s vital to empower the team to speak up about any concerns. Encouraging open communication can reveal hidden problems.

Documentation is often overlooked but is vital for quality control. Keeping precise records of production runs and defects can reveal trends over time. This data is valuable for identifying recurring issues. Yet, many teams forget to review it consistently. Reflection on past performances can guide future improvements and enhance overall quality.

Injection Moulding Process Quality Control Metrics

Related Posts

-

Unwavering Quality from Trusted Chinese Manufacturers in Best Plastic Mold Solutions

-

How to Maximize Efficiency in Plastic Injection Molding: Strategies and Industry Insights

-

Why is Plastic Injection Mold Tooling Essential for Effective Manufacturing

-

Unveiling the Science Behind Injection Molding: A Comprehensive Guide for Beginners

-

Top 10 Benefits of Polyethylene Injection Molding You Should Know?

-

What is the Plastic Injection Moulding Process Explained?