Why Choose Injection Moldable Plastics for Your Projects?

In today's manufacturing landscape, the choice of materials significantly affects project success. Injection moldable plastics have gained popularity for various reasons. They offer flexibility in design and functionality, enabling complex shapes with precision.

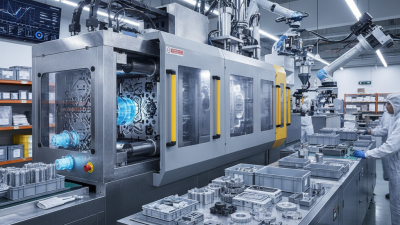

Using injection moldable plastics can drive efficiency. Their production process allows for rapid output, which is critical for meeting tight deadlines. Additionally, they can be tailored for specific applications, enhancing performance and durability. However, there are challenges to consider, such as the initial costs and the need for specialized equipment.

While injecting moldable plastics is a smart decision, it is essential to weigh the pros and cons. Some projects may benefit from alternative materials. Hence, understanding your project's requirements is crucial. Ultimately, the right choice can lead to innovative solutions and improved outcomes.

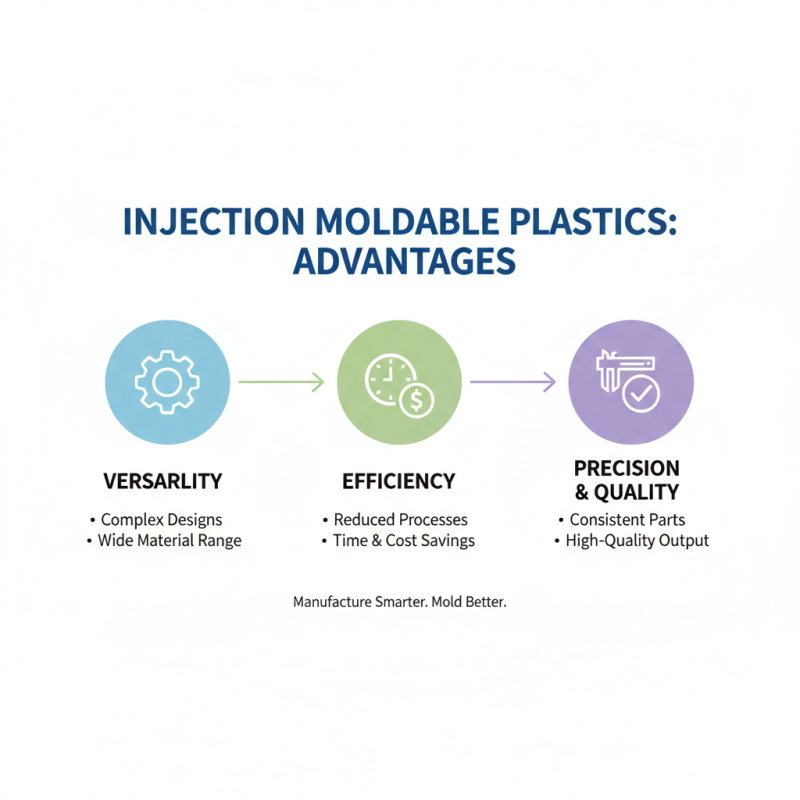

Benefits of Injection Moldable Plastics in Manufacturing

Injection moldable plastics offer distinct advantages in manufacturing. These materials are known for their versatility and efficiency. They can be shaped into complex designs with ease. This capability often reduces the need for additional processes, saving both time and cost. The precision in injection molding ensures that parts produced are consistent and high-quality.

When choosing materials, consider the production volume. Injection molding excels in large-scale manufacturing. However, for smaller projects, prototype options might be better. Material selection can also affect the end product's durability and appearance. It’s crucial to evaluate all these factors.

Tip: Always run a cost analysis for your project. Understand the trade-offs between different materials. Keep in mind that all plastics behave differently under variations in temperature and load. Conducting tests can help identify unexpected performance issues. Before finalizing your choice, reflect on how environmental factors may affect your product. This foresight can lead to better decision-making.

Cost Efficiency of Injection Moldable Plastics for Projects

Injection moldable plastics offer significant cost efficiency for various projects. They allow for mass production, minimizing material waste and reducing overall costs. The quick production cycle can lower labor expenses. This aspect is vital for businesses aiming to stay competitive in a tight market.

When considering injection moldable plastics, think about the design complexity. A simple design can yield lower costs. However, intricate designs may require more investment upfront. Reflect on your project’s needs and budget. Sometimes, a more straightforward approach can be more cost-effective in the long run.

Tips for cost savings: Focus on standard sizes and shapes. Custom molds can be expensive and time-consuming. Also, evaluate the resin types. Some materials provide better cost efficiency depending on the project. Keep in mind that while upfront costs matter, long-term durability is crucial for future savings.

Design Flexibility Offered by Injection Moldable Plastics

Injection moldable plastics offer exceptional design flexibility for various applications. With advancements in technology, manufacturers can create intricate geometries and customized shapes that fit specific project requirements. A report by the Plastics Industry Association notes that around 45% of plastics are produced using injection molding techniques. This popularity underscores its capability to produce complex designs efficiently.

The versatility of injection moldable plastics extends beyond simple shapes. Designers can experiment with textures and performance characteristics. For instance, integrating different colors and finishes can significantly enhance aesthetic appeal. However, achieving the perfect combination of function and beauty can be challenging. It requires careful consideration of material properties and molding conditions. Often, minor adjustments lead to substantial changes, which can be both an opportunity and a risk.

Additionally, various types of plastics can be used in conjunction with injection molding. Each has unique properties that can impact the final product. Balancing attributes like durability, weight, and cost is not always straightforward. The right choice might lead to optimal performance, while the wrong one could hinder production efficiency. Hence, evaluating the design requirements and expected application carefully is crucial.

Durability and Performance of Injection Moldable Plastics

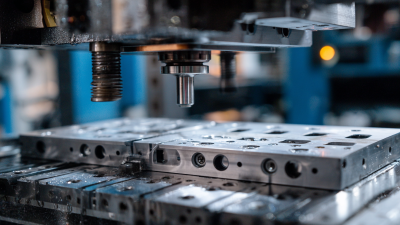

Injection moldable plastics offer remarkable durability and performance, making them a top choice for various projects. Recent industry reports show that injection moldable plastics can withstand extreme conditions. They often endure temperatures as high as 120°C without losing structural integrity. Such resilience makes them ideal for automotive and consumer goods manufacturing.

These plastics can also resist chemical exposure. For example, polypropylene exhibits excellent resistance to solvents and acids. This quality underscores their versatility in applications ranging from medical devices to household products. Furthermore, data indicates that components made from these materials have a lower failure rate compared to traditional materials. However, achieving this durability requires precise control over the injection molding process.

Despite these advantages, challenges remain. For instance, achieving consistent quality during production can be complex. Variance in temperature, pressure, and material quality can lead to defects. Addressing these issues demands experienced operators and advanced technology. Identifying the right material for specific applications is equally critical. Not all injection moldable plastics are suitable for every need, and missteps can result in costly failures.

Why Choose Injection Moldable Plastics for Your Projects? - Durability and Performance of Injection Moldable Plastics

| Property | Description | Performance Score (1-10) |

|---|---|---|

| Durability | High resistance to impact and wear. | 9 |

| Weight | Lightweight materials compared to metals. | 8 |

| Corrosion Resistance | Not prone to rust or corrosion. | 10 |

| Thermal Stability | Can withstand a range of temperatures without deforming. | 8 |

| Aesthetic Options | Available in various colors and finishes. | 9 |

| Production Efficiency | Fast and cost-effective mass production. | 9 |

Sustainability Considerations in Using Injection Moldable Plastics

The sustainability of injection moldable plastics is a growing concern in today's manufacturing landscape. According to a report by the EPA, plastics account for over 20% of the waste in landfills. This statistic highlights the need for environmentally friendly alternatives in production. Injection moldable plastics can be produced from renewable resources, which may help reduce the carbon footprint.

Another important consideration is the energy consumption during production. A study published in the Journal of Cleaner Production found that using less energy in manufacturing can significantly lower greenhouse gas emissions. Often, injection molding requires less energy compared to other processes. However, the process still has its drawbacks. The recycling rates of these plastics remain relatively low. Many consumers are not fully aware of how to recycle items made from these materials.

The end-of-life management of injection moldable plastics remains a complex challenge. Material degradation can affect recyclability. Some types of plastics degrade chemically, making them unsuitable for recycling without extensive processing. Ongoing innovations in biodegradable options could address some of these concerns. Yet, the market needs to foster improvements in education and technology surrounding this issue. Many products still end up in landfills instead of being recycled or repurposed. This calls for a collective effort to promote better practices in the industry.

Related Posts

-

Exploring the Future: How Plastic Injection Molding Shapes a $300 Billion Industry

-

How to Master Injection Mold Making Techniques for Cost Effective Production

-

Why Injection Tooling is Essential for Efficient Manufacturing Processes

-

Innovative Injection Molding Design Trends to Watch at the 2025 Canton Fair

-

Achieving the Best Plastic Injection Molding Mold Standards Through Effective Design Techniques

-

5 Essential Tips for Mastering Plastic Engineering in the Next Decade