2026 How to Choose a Geomembrane Welding Machine?

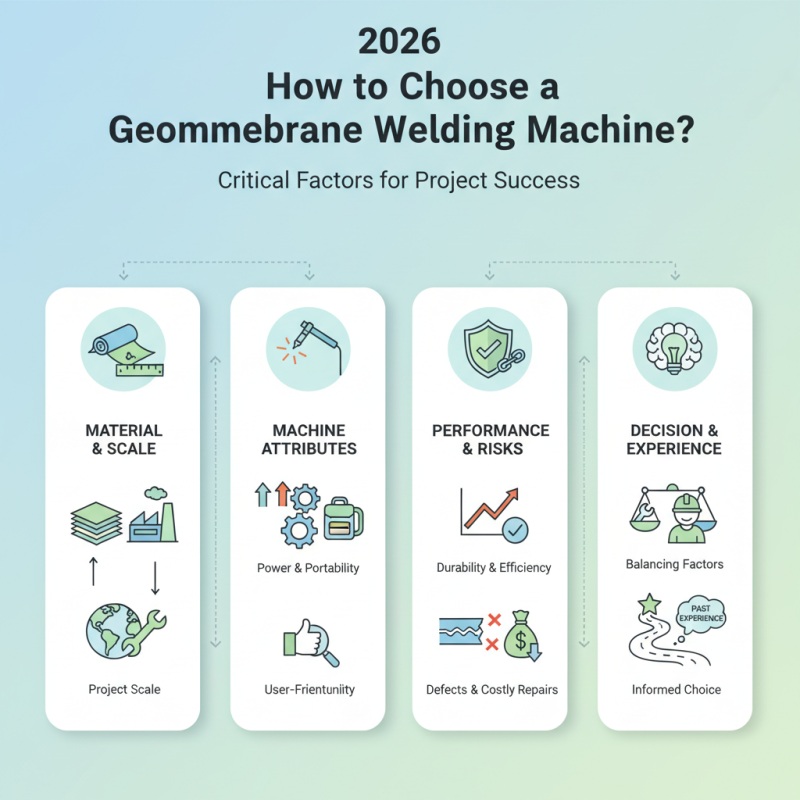

Choosing the right geomembrane welding machine is critical for successful projects. With many options available, decision-making can be overwhelming. The right machine ensures durability and efficiency in welding geomembranes.

Factors like material type, thickness, and project scale influence your choice. A good machine should accommodate various geomembranes, providing flexibility for different applications. Additionally, user-friendliness is essential to ensure productivity on the job site.

Consider the machine's power and portability. Heavy machines may not be practical for all projects. Speed and precision are also vital; a poorly chosen machine can lead to defects and costly repairs. Reflecting on past experiences can reveal insights into what works best. Making the right choice involves balancing these details carefully.

Understanding Geomembrane Welding Machines and Their Applications

geomembrane welding machines play a crucial role in various applications. These machines are used for creating watertight seals in plastic materials. They are widely applied in landfills, ponds, and containment structures. Choosing the right machine can be overwhelming due to the variety of options available. Understanding their applications is essential.

When selecting a welding machine, consider the materials involved. Different geomembranes require specific techniques for optimal bonding. For instance, high-density polyethylene (HDPE) may need a different approach than low-density polyethylene (LDPE). Pay attention to the thickness of the materials. Thicker geomembranes demand machines with more power and precision.

Tips: Always assess the environment where the welding will occur. Factors like temperature and humidity can impact the welding process. A portable machine may be beneficial for remote locations. Also, train your team properly. The quality of the welds hinges on skilled operators. They should be familiar with the machine’s settings and techniques.

Don't overlook maintenance. Regular checks can prevent machine failures during crucial projects. Invest time in understanding the equipment. It pays off in the long run. You might encounter challenges in the learning curve. It’s essential to remain patient and open to feedback. Make adjustments based on past experiences for continuous improvement.

Key Features to Look for in a Geomembrane Welding Machine

When choosing a geomembrane welding machine, key features play a critical role. One essential aspect is the welding technology employed. Machines may utilize hot wedge or extrusion welding techniques. The choice affects the material compatibility and welding speed. Reports indicate that hot wedge welding offers superior speed, completing a seam at about 5 to 10 meters per minute. This efficiency is essential for large-scale projects.

Another important feature is the temperature control system. Precise temperature regulation ensures quality welds. Inadequate temperature can lead to weak seams. A study found that a 5°C discrepancy can reduce the tensile strength of welds by over 20%. Therefore, a reliable control system is non-negotiable.

The machine's portability also matters significantly. Projects often occur on uneven or remote sites. Lightweight and compact machines ease transportation and setup. However, some models sacrifice stability for portability. This trade-off can affect performance. Therefore, assessing the balance of these features is crucial when selecting a geomembrane welding machine.

2026 How to Choose a Geomembrane Welding Machine? - Key Features to Look for in a Geomembrane Welding Machine

| Feature | Description | Importance |

|---|---|---|

| Welding Technology | Different machines utilize extrusion, hot wedge, or dielectric processes for welding. | Choosing the right technology for the specific application enhances weld quality and efficiency. |

| Temperature Control | Digital or automatic controls for accurate temperature regulation. | Critical for achieving proper weld without damaging the geomembrane materials. |

| Portability | Weight and design that make the machine easy to transport and set up on site. | Increases project efficiency by allowing quick deployment in different locations. |

| Weld Width | Variable weld width options to accommodate different geomembrane sizes. | Important for various applications to ensure the strength and reliability of the weld. |

| Power Source | Availability of electric, gas, or battery-powered options. | Flexibility to work in diverse environments and conditions. |

| User Interface | Ease of use, with intuitive controls and clear displays. | Reduces training time and increases operational efficiency. |

Types of Welding Techniques for Geomembranes Explained

When considering geomembrane welding, understanding the different techniques is essential. Hot air welding is one of the most commonly used methods. It uses a stream of hot air to melt the edges of geomembranes. This technique is versatile and can handle various materials. However, achieving a perfect seal can be tricky, requiring skilled operators for best results.

Another widely employed method is extrusion welding. This technique melts thermoplastic material and directly applies it to the seam. This can create robust joints, ideal for high-stress areas. However, it may lead to a thicker seam, which can be a disadvantage in some projects. Proper adjustment of temperature and speed is critical to avoid weak joints.

Lastly, there’s radio frequency welding. This method uses electromagnetic energy to produce heat, causing the geomembrane edges to fuse. It offers precise control but may not be suitable for all types of geomembranes. Each technique has its strengths and weaknesses, making it crucial to evaluate the project requirements before deciding.

Factors Influencing the Selection of a Welding Machine

Choosing the right geomembrane welding machine involves several key factors. One significant influence is the material you will be working with. Different geomembranes, such as HDPE or LLDPE, require distinct welding techniques and temperature settings. According to a report by the Geosynthetics Materials Association, specific welding parameters can vary based on the thickness and type of membrane. Incorrect settings can lead to weak seams.

Another crucial factor is the machine's versatility. A good welding machine should handle different projects efficiently. Operators often find machines that can switch between various welding methods are more beneficial. However, sometimes machines may struggle with complex designs or thicker materials, which raises concerns about reliability. Documentation from industry studies emphasizes that an adaptable machine may reduce project downtime, but operators should be cautious about overextending the machine’s capabilities.

Finally, consider the ease of use and ergonomic design. Training staff on complicated machines can take time. This can lead to delays in productivity. Safety features are also important. Regular maintenance is essential for any welding machine. Reports indicate that neglecting this aspect can result in machine failures. Balancing functionality, ease of use, and safety can ensure better welding quality and longer machine life, but it's a challenging balance to achieve.

Factors Influencing the Selection of a Geomembrane Welding Machine

Maintenance and Care Tips for Geomembrane Welding Machines

Maintaining geomembrane welding machines is crucial for ensuring optimal performance and longevity. Regular inspections can help identify issues before they become significant problems. Look for wear and tear on hoses, nozzles, and heating elements. Any damage can affect welding quality and should be addressed immediately.

Tips: Always clean the machine after use. This simple act can prevent debris from causing malfunction. Check connections regularly to ensure they are tight and secure, as loose connections can lead to inconsistent heating. It’s wise to consult operational manuals for maintenance schedules.

Routine lubrication of moving parts is equally important. Grease can help prevent rust and mechanical failures. Remember, ignoring maintenance could lead to much costlier repairs later. A little care goes a long way in keeping your welding machine in top shape.