The Future of Best Plastic Injection Mold Design: Innovations Driving Global Manufacturing Growth

As we look toward 2025, the landscape of global manufacturing is poised for significant transformation, particularly in the realm of plastic injection mold design. Recent industry reports forecast that the global plastic injection molding market will reach approximately $400 billion by 2025, growing at a CAGR of 5.8% from 2020. Innovations in materials, automation, and technology are driving this growth, enabling manufacturers to enhance efficiency and reduce costs while maintaining high standards of quality. With the rising demand for lightweight and durable components across various sectors, including automotive, healthcare, and consumer goods, the importance of advanced plastic injection mold design cannot be overstated. This blog will explore the key trends and innovations shaping the future of this crucial industry, offering insights on how manufacturers can leverage these advancements to remain competitive in an increasingly globalized market.

Emerging Technologies Shaping Plastic Injection Mold Design for 2025

As we look toward 2025, emerging technologies are set to redefine the landscape of plastic injection mold design. According to a report by Smithers, the global market for plastic injection molding is anticipated to reach $360 billion by 2025, driven by advancements in materials and manufacturing processes. One of the most significant innovations is the integration of artificial intelligence and machine learning algorithms, which streamline design processes, enhance precision, and significantly reduce production times. AI-driven optimization tools are enabling engineers to create complex molds that maximize efficiency while minimizing material waste.

Moreover, the adoption of additive manufacturing techniques, particularly 3D printing, is revolutionizing mold fabrication. A study by Grand View Research indicates that the 3D printing market for molds is expected to grow at a CAGR of 21.6% from 2023 to 2030. This technology allows for rapid prototyping and customization, enabling manufacturers to respond swiftly to market demands. As sustainability becomes a critical concern, bioplastics and recyclable materials are also gaining traction in mold design, aligning with the growing emphasis on environmental responsibility in manufacturing. The convergence of these technologies promises a transformative impact on plastic injection molding, driving innovation and efficiency in global manufacturing.

The Future of Best Plastic Injection Mold Design: Innovations Driving Global Manufacturing Growth

This chart illustrates the projected investment in key innovations driving the future of plastic injection mold design by 2025. Significant growth is expected in areas such as 3D printing and automation, which are set to transform the efficiency and sustainability of manufacturing practices.

Sustainable Practices in Injection Molding: A Greener Manufacturing Future

The injection molding industry stands at a transformative crossroads, increasingly aligning with sustainable practices that promise a greener manufacturing future. As environmental concerns intensify, innovations in sustainable materials, such as bio-polyethylene and biodegradable composites, have emerged as viable alternatives to conventional plastics. These advanced materials not only help mitigate waste but also cater to growing consumer demand for eco-friendly products.

Moreover, the incorporation of recycled polymers and natural waste materials into additive manufacturing is gaining momentum. This movement reflects a broader trend in the plastic injection molding sector, with manufacturers embracing circular economy principles to reduce their environmental footprint. By integrating cutting-edge recycling technologies and adopting sustainable manufacturing practices, the industry is poised to drive significant change, ensuring that future production processes harmonize with the ecosystem while meeting market needs. As we look ahead, these innovations will undoubtedly shape the landscape of global manufacturing and set a precedent for sustainability.

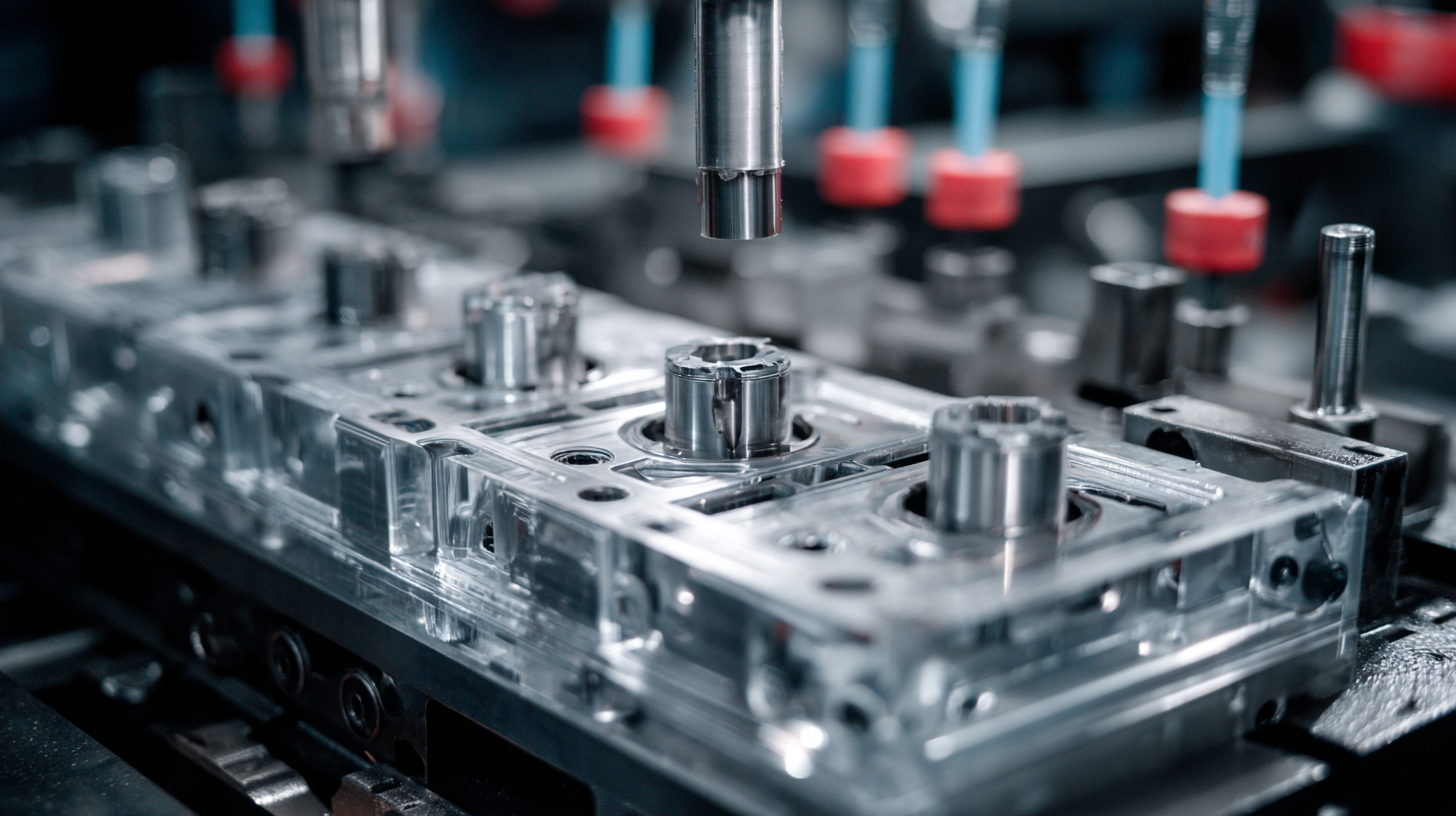

Automation and Robotics: Optimizing Efficiency in Mold Production

In the fast-evolving landscape of plastic injection mold design, automation and robotics are setting new standards for efficiency and precision. As manufacturers face increasing pressure to reduce costs and enhance productivity, robotic systems are stepping in to streamline the mold production process. These advanced machines can perform repetitive tasks with unmatched accuracy and speed, minimizing errors and maximizing output. By integrating robotics into the workflow, companies not only save time but also reduce labor costs, allowing their human workforce to focus on more complex and creative aspects of production.

Moreover, the incorporation of smart technology into automated systems has revolutionized mold design. Intelligent software now provides real-time data analytics, allowing for immediate adjustments in the production process. This capability ensures that any potential issues are identified and rectified without causing significant delays. With the ability to monitor machine performance and quality control in real time, manufacturers can achieve higher standards of quality and consistency. The synergy between automation, robotics, and smart technology heralds a new era in plastic injection mold design, driving significant growth and innovation in the global manufacturing sector.

The Future of Best Plastic Injection Mold Design: Innovations Driving Global Manufacturing Growth

| Innovation Type | Description | Impact on Manufacturing | Expected Growth Rate (%) |

|---|---|---|---|

| Automation | Integration of automated systems to perform repetitive tasks. | Increases production speed and consistency. | 15% |

| Robotics | Use of robots for precise and complex mold making. | Enhances precision and reduces errors. | 20% |

| 3D Printing | Utilization of 3D printing technology for mold prototypes. | Reduces lead time for mold creation. | 25% |

| Smart Sensors | Sensors monitor mold and machine performance in real-time. | Improves predictive maintenance and reduces downtime. | 18% |

| AI and Machine Learning | Algorithms optimize mold design and production processes. | Enhances design efficiency and reduces waste. | 30% |

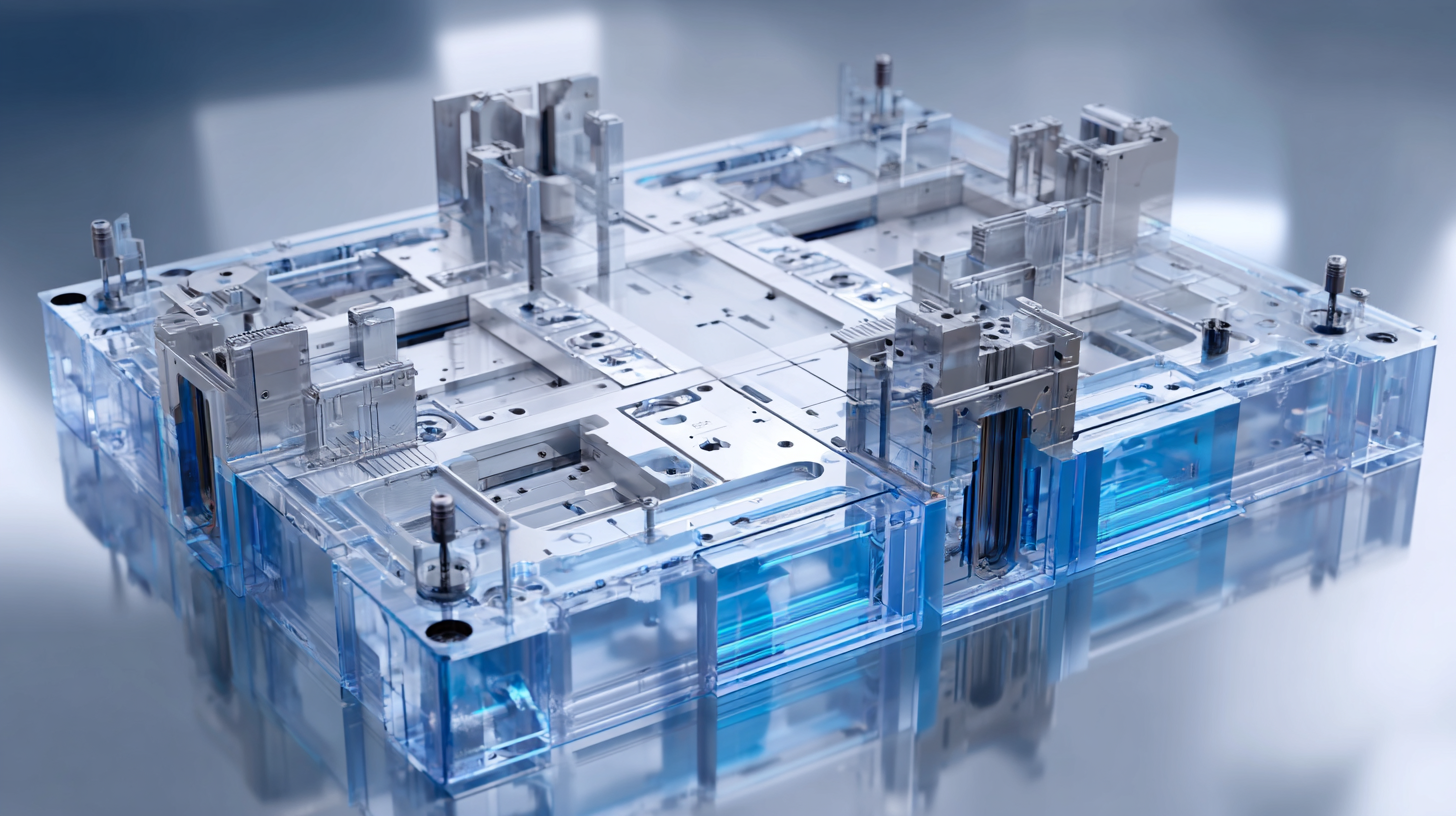

Advanced Materials Revolutionizing Injection Mold Capability and Design

The evolution of plastic injection mold design is seeing a significant shift, driven by advanced materials that are revolutionizing capabilities and shapes. These innovations are not just about improving efficiency; they're about redefining the very boundaries of what's possible in manufacturing. New materials, such as high-performance thermoplastics and bio-based composites, offer enhanced strength, heat resistance, and sustainability, catering to the increasing demand for eco-friendly products.

Tip: When selecting materials for your injection molds, consider the specific requirements of your application. High-temperature thermoplastics, for instance, can withstand greater thermal stress, making them suitable for industries such as automotive and aerospace. Conversely, if sustainability is a priority, exploring bio-based materials could align your manufacturing processes with environmental goals.

Another emerging trend is the integration of smart technologies into mold design, allowing for real-time monitoring and adjustments during the injection process. This not only enhances precision and reduces waste but also optimizes production timelines.

Tip: Embrace smart tech by investing in sensors and automation solutions that can track variables like temperature and pressure. This proactive approach can help you identify potential issues before they escalate, ensuring consistent quality and minimizing downtime.

Digital Transformation: How AI and IoT Are Redefining Manufacturing Processes

In the ever-evolving landscape of manufacturing, digital transformation plays a crucial role in redefining processes through innovations like artificial intelligence (AI) and the Internet of Things (IoT).

AI algorithms can now optimize every phase of plastic injection mold design, enhancing precision and reducing waste. This shift not only improves efficiency but also empowers manufacturers to respond swiftly to market demands, ensuring that production meets consumer expectations without delay.

Tips for integrating AI in your manufacturing process include starting with pilot projects to assess impact before a full-scale rollout. Additionally, invest in training your workforce to leverage AI tools effectively. The IoT complements this by providing real-time data on machine performance and environmental conditions, allowing for proactive maintenance and process adjustments. Utilizing these technologies together creates a synergistic effect that drives productivity while minimizing costs.

As these innovations continue to shape the future of manufacturing, companies that embrace AI and IoT early will be better positioned to outperform competitors. To stay ahead, regularly review your processes and incorporate feedback from your teams to adapt to new technologies swiftly. This adaptive approach can significantly enhance your manufacturing capabilities while keeping your operation lean and efficient.