Understanding the Role of Injection Molding Design in Sustainable Manufacturing

Injection molding design plays a pivotal role in the realm of sustainable manufacturing, as it significantly influences the environmental impact of production processes. According to a report from the Association for Plastic Recyclers, sustainable injection molding practices can reduce material waste by up to 20% and energy consumption by over 30% compared to traditional methods. As industries increasingly prioritize sustainability, effective injection molding design becomes essential for minimizing ecological footprints while maintaining product quality. A study published by the Conference on Sustainable Manufacturing highlights that adopting advanced injection molding techniques can lead to a circular economy, where plastic products are designed for longevity and recyclability. Thus, implementing innovative injection molding design not only enhances operational efficiency but also contributes to a more sustainable future in manufacturing.

The Environmental Impact of Injection Molding in Sustainable Manufacturing

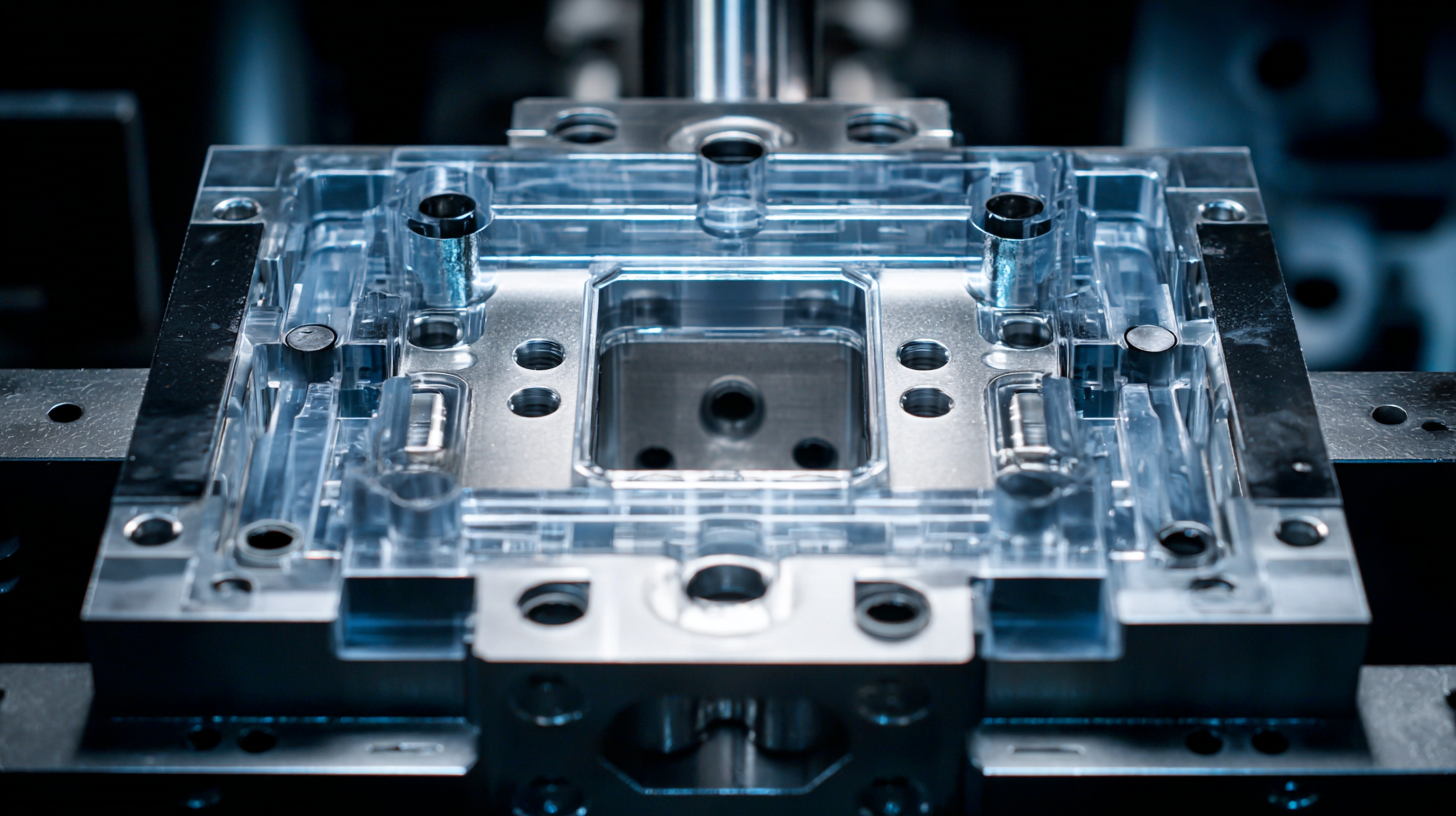

The environmental impact of injection molding in sustainable manufacturing is an increasingly important consideration as industries strive to minimize their carbon footprints and enhance resource efficiency. Injection molding, a widely used manufacturing process for producing plastic parts, can contribute to sustainability when designed with environmental factors in mind. The choice of materials, energy consumption during production, and waste management are critical elements that affect the overall ecological footprint of this process.

One significant environmental concern associated with injection molding is the type of plastics utilized. By opting for bioplastics or recycled materials, manufacturers can substantially reduce the environmental impact of their products. Additionally, innovations in mold design can lead to more efficient use of materials, minimizing scrap and maximizing the functional lifespan of components. Furthermore, energy-efficient machinery and temperature control systems can lower energy consumption and associated emissions during production, making the process more sustainable.

Moreover, addressing post-production waste is crucial for enhancing sustainability in injection molding. Implementing closed-loop systems allows for the repurposing of scrap materials back into the manufacturing process, reducing landfill contributions and promoting a circular economy. Through thoughtful design and strategic material choices, injection molding can play a pivotal role in advancing sustainable manufacturing practices while mitigating its environmental impact.

Understanding the Role of Injection Molding Design in Sustainable Manufacturing - The Environmental Impact of Injection Molding in Sustainable Manufacturing

| Aspect | Impact | Sustainability Strategies | Potential Benefits |

|---|---|---|---|

| Materials Used | Environmental degradation due to non-biodegradable plastics | Use of bio-based or recycled materials | Reduced carbon footprint |

| Energy Consumption | High energy usage during the molding process | Implementation of energy-efficient machinery | Lower operational costs |

| Waste Generation | Production waste and scraps contribute to landfill | Recycle and reuse of production scrap | Minimized waste disposal costs |

| Supply Chain | Environmental impacts from transportation of materials | Locally sourced materials and suppliers | Reduced transportation emissions |

| Product Lifecycle | Single-use products lead to increased waste | Design for recyclability and reusability | Improved product longevity and sustainability |

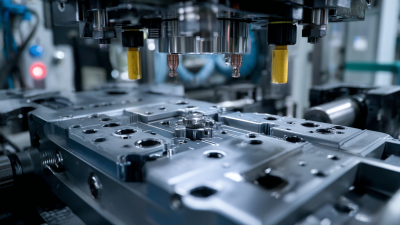

Integrating Digital Technologies to Optimize Injection Molding Processes

The integration of digital technologies into injection molding processes is revolutionizing sustainable manufacturing. By employing digital twin technology, manufacturers can create virtual replicas of their production systems, enabling real-time monitoring and optimization of processes. This approach not only enhances efficiency but also minimizes waste and energy consumption, contributing to a more sustainable manufacturing environment.

Tips: Implementing a digital twin can greatly improve your design phase. Start by mapping out your entire injection molding process, paying attention to key performance indicators that matter most to your sustainability goals. Utilizing data from these virtual models allows for rapid iterations of design changes, ultimately leading to better resource management.

Furthermore, advancements in intelligent data-driven design systems can address the complexities of modern mold design. By constructing knowledge graphs that incorporate deep semantic understanding, manufacturers can significantly reduce error rates associated with traditional design methods. This transition towards a more data-centric approach ensures that processes are not only optimized for performance but also for environmental impact.

Tips: Embrace data analytics in your workflow. Regularly analyze the performance data generated from your digital twin to identify trends and areas where sustainability can be improved. Foster a culture of continuous improvement by keeping your design teams engaged with data insights to reinforce informed decision-making.

Evaluating Material Efficiency: Reducing Waste in Injection Molding Design

Injection molding design plays a pivotal role in sustainable manufacturing, particularly when it comes to material efficiency. By optimizing the design of mold components, manufacturers can significantly reduce waste during the production process. This involves careful consideration of the shape and size of the parts being produced, as well as the arrangement of the cavities in the mold.

Advanced simulation tools can aid designers in predicting flow behavior, allowing them to create more efficient designs that require less material without compromising the integrity of the final product.

Moreover, selecting the right materials can enhance sustainability efforts in injection molding. Biodegradable plastics and recycled materials are increasingly being utilized, as they decrease the environmental footprint of the manufacturing process.

Design strategies, such as incorporating features that minimize the amount of material needed—like ribbing for structural support—also play a crucial role in reducing waste. By focusing on these design considerations, manufacturers can achieve not only economic benefits but also contribute to a more sustainable future in the industry.

Lifecycle Assessment of Injection Molded Products in Sustainable Practices

Lifecycle assessment (LCA) is a crucial tool for evaluating the environmental impact of injection molded products within sustainable manufacturing practices. This comprehensive analysis encompasses all phases of a product's life, from raw material extraction through production, usage, and eventual disposal or recycling. By assessing various environmental indicators, such as greenhouse gas emissions, energy consumption, and resource depletion, manufacturers can identify hotspots where improvements can be made. This enables a more sustainable approach by informing design decisions that minimize the ecological footprint.

In the context of injection molding, LCA allows for the optimization of material selection and process efficiency. Advanced polymers that are recyclable or biodegradable can be prioritized, while the design of molds can be refined to reduce waste and energy usage during production. By integrating LCA into the design phase, companies can ensure that their injection molded products not only meet performance standards but also align with sustainable practices. Through this iterative assessment, manufacturers can contribute to a circular economy, where materials are reused and repurposed, minimizing environmental impact and promoting resource conservation.

Understanding the Role of Injection Molding Design in Sustainable Manufacturing

This chart illustrates the lifecycle assessment of injection molded products in sustainable practices, comparing various environmental impact categories.

The Future of Injection Molding: Innovations for Eco-Friendly Manufacturing

The future of injection molding in sustainable manufacturing is increasingly driven by innovations that prioritize eco-friendliness. As industries recognize the environmental impact of traditional production methods, advancements in injection molding technology are emerging to address these concerns. One such innovation is the development of bioplastics, which are derived from renewable sources and offer a viable alternative to conventional petroleum-based plastics. These materials not only reduce reliance on fossil fuels but also improve the overall environmental footprint of manufactured products.

Additionally, improvements in energy efficiency during the injection molding process are paving the way for greener manufacturing practices. Companies are increasingly adopting electric injection molding machines that consume less energy compared to their hydraulic counterparts. This shift not only lowers operational costs but also minimizes greenhouse gas emissions associated with the production process. Furthermore, advancements in mold design, such as the incorporation of conformal cooling channels, enhance heat transfer efficiency, resulting in shorter cycle times and reduced energy consumption. Collectively, these innovations signify a transformative shift towards a more sustainable future in injection molding, reinforcing its critical role in eco-friendly manufacturing.

Related Posts

-

How to Optimize Your Injection Molding Tooling Processes for Maximum Efficiency

-

The Future of Precision Injection Molding Innovations and Trends

-

China's Premier Plastic Injection Tooling Solutions for a Global Market

-

How to Choose the Best Injection Molding Die for Your Production Needs: Insights from Industry Experts

-

Exploring Unique Product Features and Applications in Best Plastic Injection Mold Tooling

-

Common Challenges in the Best Plastic Injection Moulding Process