Innovative Injection Molding Design Trends to Watch at the 2025 Canton Fair

The 2025 Canton Fair, set to showcase the latest innovations in the manufacturing sector, will prominently feature cutting-edge trends in injection molding design. As the global demand for plastic products continues to rise, with the injection molding market projected to reach $438 billion by 2025 according to Grand View Research, manufacturers are increasingly adopting advanced technologies and sustainable practices. Key trends shaping the future of injection molding design include the integration of smart manufacturing, enhanced automation, and the use of eco-friendly materials, which not only improve efficiency but also address environmental concerns. Attendees of the fair can expect to see pioneering design solutions that optimize production processes, reduce waste, and adapt to rapidly changing consumer preferences, solidifying injection molding's role as a cornerstone of modern manufacturing.

Emerging Technologies in Injection Molding: Revolutionizing Production at the 2025 Canton Fair

The 2025 Canton Fair is expected to showcase groundbreaking innovations in injection molding, particularly those that leverage emerging technologies to transform production processes. One key trend is the integration of smart manufacturing solutions, which utilize artificial intelligence and machine learning algorithms to optimize production efficiency and minimize waste. These advancements enable real-time monitoring and predictive maintenance, ensuring smoother operations and significantly reducing downtime.

Another notable development in injection molding is the rise of sustainable materials and processes. Manufacturers are increasingly focusing on eco-friendly polymers and biodegradable alternatives, reflecting a growing commitment to environmental conservation. Innovations such as 3D printing and advanced tooling techniques are also paving the way for more complex designs and faster prototyping, further enhancing the versatility and functionality of injection-molded products. As exhibitors and attendees prepare for the fair, these trends highlight a significant shift towards smarter, more sustainable manufacturing practices in the injection molding industry.

Sustainable Practices in Injection Molding: Eco-friendly Materials and Processes on Display

As sustainability becomes a critical focus across industries, the injection molding sector is adapting to meet the increasing demand for eco-friendly practices. At the upcoming 2025 Canton Fair, a variety of innovative materials and processes are anticipated to dominate the landscape. Recent industry reports indicate that the global market for biodegradable plastics is expected to reach $6.68 billion by 2025, driven by rising environmental awareness and government regulations promoting sustainable practices. This trend is reflected in the injection molding designs showcased at the fair, highlighting the shift towards using materials such as PLA (polylactic acid) and other bio-based polymers.

Moreover, manufacturers are investing in more energy-efficient machinery and processes in an effort to reduce their carbon footprint. According to a report from Grand View Research, the energy-intensive nature of injection molding contributes to significant operational emissions, prompting a shift to more sustainable technologies. For instance, advancements in electric injection molding machines can reduce energy consumption by up to 70% compared to traditional hydraulic machines. Attendees at the Canton Fair will witness firsthand these transformative practices that not only lower emissions but also enhance productivity and product quality—demonstrating a resilient shift toward sustainability in the industry.

Innovative Injection Molding Design Trends to Watch at the 2025 Canton Fair

| Trend | Description | Materials | Process Innovations | Sustainability Impact |

|---|---|---|---|---|

| Biodegradable Plastics | Use of plant-based materials that decompose naturally | PLA, PHA | Low temperature processing | Reduces plastic pollution |

| Recycled Materials | Incorporating post-consumer recycled plastics into products | R-PET, R-PP | Closed-loop production techniques | Conserves resources and energy |

| Energy Efficient Machines | Advancements in machinery that consume less energy | N/A | Servo-driven technology | Decreases carbon footprint |

| Additive Manufacturing | Integrating 3D printing with injection molding | Various thermoplastics | Multi-material printing | Maximizes material usage |

| Smart Manufacturing | Utilization of IoT for enhanced efficiency | N/A | Real-time monitoring | Improves production sustainability |

Smart Manufacturing: Integrating IoT and AI in Injection Molding Solutions

As we look towards the 2025 Canton Fair, the integration of IoT and AI in injection molding represents a transformative shift in smart manufacturing. Manufacturers are increasingly adopting IoT technologies to monitor production processes in real-time, offering unprecedented insight into operational efficiencies. Sensors embedded in injection molding machines collect data that can predict machine performance, monitor material usage, and detect anomalies before they lead to failures, thereby significantly reducing downtime and maintenance costs.

Artificial intelligence further enhances these capabilities by analyzing vast amounts of data to optimize production workflows. AI algorithms can fine-tune parameters for mold designs, improving product quality and minimizing waste. Additionally, predictive analytics empowers manufacturers to make informed decisions about inventory, scheduling, and resource allocation. This synergistic approach of IoT and AI not only fosters greater innovation in injection molding solutions but also promotes sustainability by enabling a more efficient use of resources and energy throughout the manufacturing process. The trends emerging from these advancements hint at a future where injection molding becomes not only smarter but also more responsive to the evolving needs of the market.

Innovative Injection Molding Design Trends at the 2025 Canton Fair

Customization and Personalization Trends: Tailored Injection Molding Designs for Diverse Industries

The 2025 Canton Fair is set to showcase groundbreaking innovations in injection molding design, particularly emphasizing customization and personalization. As industries increasingly seek unique solutions tailored to their specific needs, the demand for bespoke injection molding designs is surging. This not only allows businesses to differentiate their products in a competitive market but also enables them to connect more intimately with their customers' preferences.

In response to this trend, manufacturers are leveraging advanced technologies such as 3D printing and computer-aided design (CAD) to create customizable molds that cater to diverse applications. These technologies facilitate rapid prototyping and iteration, allowing companies to experiment with designs and materials that reflect their brand identities. Furthermore, personalization in injection molding is gaining traction as consumers seek products that resonate with their individual tastes and lifestyles, pushing manufacturers to innovate continuously and provide adaptable solutions across various sectors, from automotive to consumer goods.

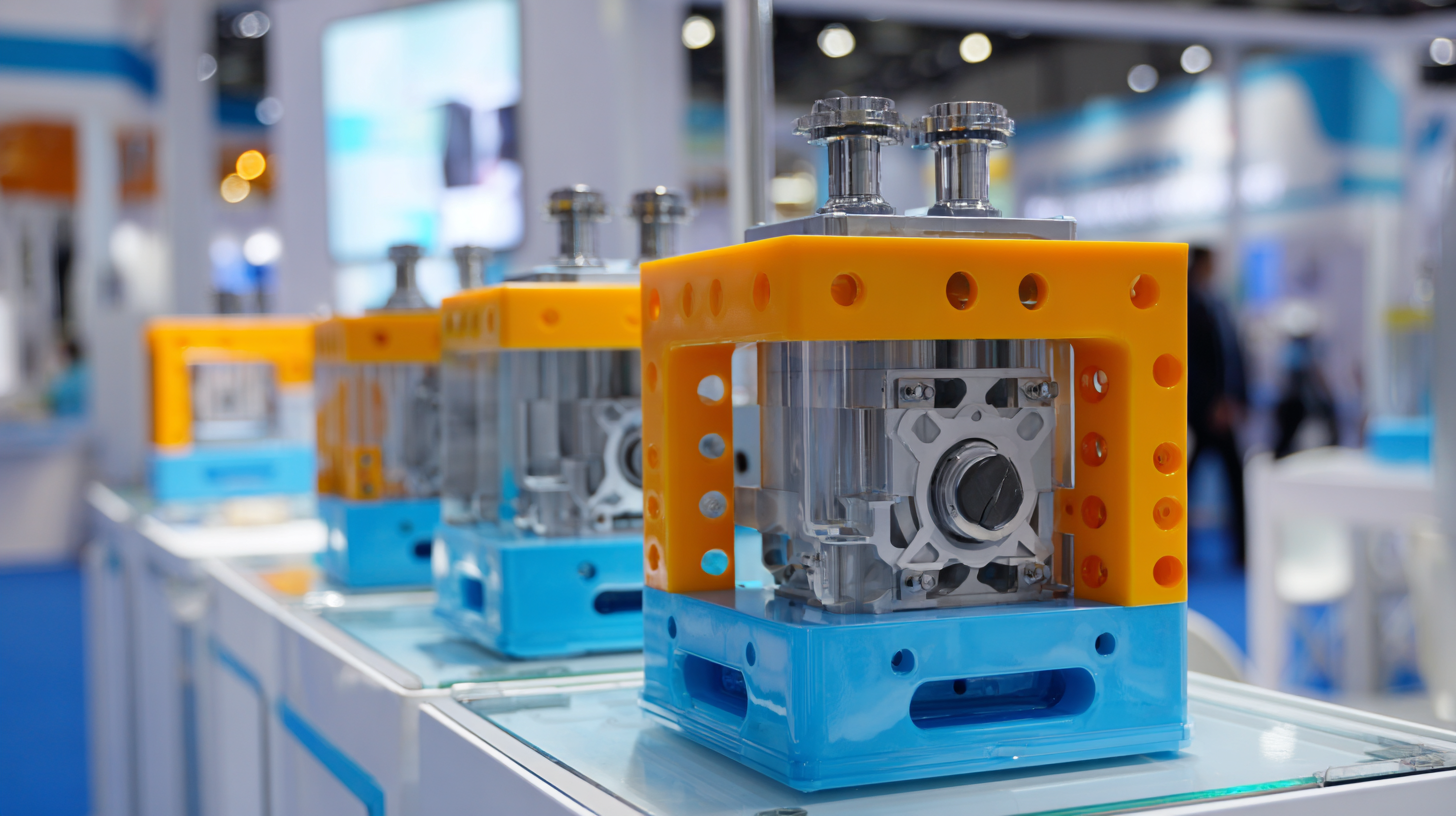

Advancements in Mold Design: Innovations for Efficiency and Cost-Effectiveness at the Fair

As the 2025 Canton Fair approaches, advancements in mold design are set to take center stage, showcasing innovative solutions that emphasize both efficiency and cost-effectiveness. The integration of new materials and technologies has transformed traditional injection molding processes. Manufacturers are increasingly utilizing lightweight and durable materials that not only reduce production costs but also enhance the durability of molds. These innovations allow for more complex designs that can be produced at lower energy consumption rates, underscoring a commitment to sustainable manufacturing.

In addition to materials, advancements in digital technology have enabled more precise mold designs through computer-aided design (CAD) and simulation software. These tools provide real-time analysis, allowing designers to optimize molds for better performance and faster production times. Moreover, the use of automation in the manufacturing of molds is streamlining the production process, significantly reducing lead times and minimizing human error. As industry leaders gather at the Canton Fair, the continuous evolution in mold design promises to set new benchmarks for efficiency and economical production practices.

Related Posts

-

How to Choose the Right Injection Tooling for Your Manufacturing Needs

-

Unlocking the Advantages of Best Injection Tooling in Modern Manufacturing Processes

-

How to Master the Art of Injection Mold Making for Your Business Success

-

10 Reasons Precision Injection Molding Is the Best Choice for Your Business

-

How to Choose the Best Injection Molding Die for Your Production Needs: Insights from Industry Experts

-

China's Premier Plastic Injection Tooling Solutions for a Global Market