Why Injection Tooling is Essential for Efficient Manufacturing Processes

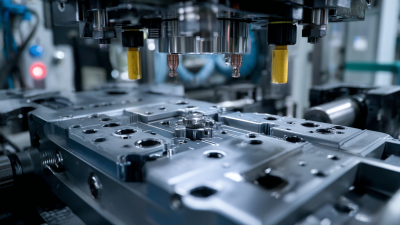

In the realm of modern manufacturing, efficiency and precision are paramount to meeting the increasing demands of various industries. One of the pivotal components that underpins these demands is injection tooling. This process involves the use of specialized molds to produce complex parts and products both quickly and accurately, thereby streamlining production timelines and reducing waste. As manufacturing continues to evolve, the significance of injection tooling becomes increasingly clear, serving not only as a means to enhance design flexibility but also to improve overall quality.

The efficiency garnered from effective injection tooling enables companies to respond adeptly to market changes, allowing for rapid prototyping and reduced lead times. This adaptability is crucial in a competitive landscape, where speed and reliability can distinguish a successful operation from its counterparts. Moreover, the robustness of injection tooling ensures consistency across large production runs, contributing to lower defect rates and higher customer satisfaction. In this context, understanding the vital role of injection tooling in manufacturing processes is essential for any organization aiming to optimize its operations and maintain a competitive edge.

Importance of Injection Tooling in Modern Manufacturing

Injection tooling plays a crucial role in modern manufacturing by enhancing production efficiency and ensuring high-quality outputs. In an industry where precision and speed are paramount, the use of injection molds allows manufacturers to produce complex parts with intricate designs accurately and consistently. This process reduces waste and minimizes the time needed for production, ensuring that products can be brought to market swiftly, thus maintaining a competitive edge.

Furthermore, effective injection tooling contributes to cost-efficiency in the manufacturing process. The durability and reusability of injection molds mean that initial investments, though significant, pay off over time through lower per-unit production costs. This adaptability is particularly beneficial for manufacturers who need to scale operations based on market demands, allowing for flexibility without compromising on quality. As companies strive to optimize their production lines, injection tooling becomes an indispensable component of their strategy, addressing the dual goals of efficiency and product excellence.

Importance of Injection Tooling in Modern Manufacturing

Overview of the Injection Molding Process

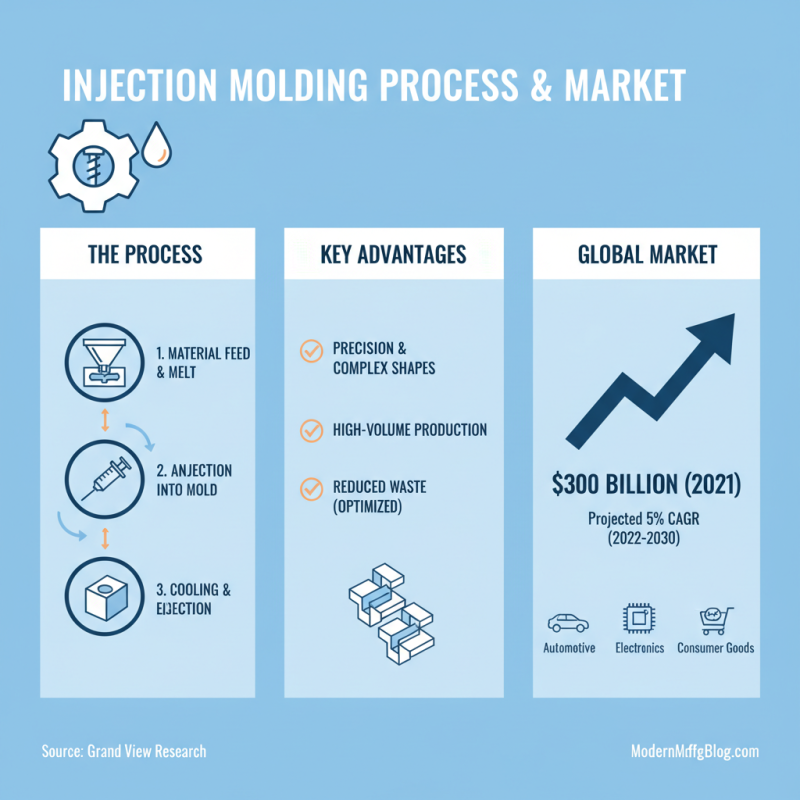

The injection molding process is a cornerstone of modern manufacturing, particularly in industries that demand precision and efficiency. This method involves injecting molten material into a mold to create complex shapes, widely used for producing plastic parts and components. According to a report by Grand View Research, the global injection molding market size was valued at approximately $300 billion in 2021 and is projected to expand at a compound annual growth rate (CAGR) of around 5% from 2022 to 2030. The substantial growth underscores its importance in various sectors, including automotive, electronics, and consumer goods.

During the injection molding process, several key steps are involved: melting raw material, injecting it into a mold, cooling to solidify, and ejecting the finished part. The use of advanced injection tooling can significantly improve cycle times and reduce material waste, leading to more sustainable practices in manufacturing. A study from the Society of Plastics Engineers highlights that optimizing injection parameters can enhance production efficiency by up to 20%, making it essential for manufacturers to invest in high-quality tooling systems that allow for precise control during the entire process. As companies strive for operational excellence, understanding the intricacies of injection molding becomes vital for remaining competitive in a rapidly evolving marketplace.

Key Benefits of Efficient Injection Tooling Systems

Efficient injection tooling systems play a crucial role in streamlining manufacturing processes across various industries. One of the primary benefits of these systems is their ability to enhance precision and consistency in production. High-quality molds ensure accurate shapes and dimensions, reducing the need for rework or adjustments. This precision not only upholds product integrity but also minimizes material waste, leading to increased sustainability in manufacturing.

Another significant advantage of efficient injection tooling is the reduction in cycle times. Advanced tooling techniques and technologies can significantly speed up the injection molding process, allowing manufacturers to produce larger quantities in shorter periods. This increased throughput contributes to reduced operational costs and can lead to improved profitability. Moreover, adaptable tooling designs enable manufacturers to pivot quickly in response to market demands or product variations, ensuring flexibility in production lines. Overall, the integration of efficient injection tooling systems is essential for optimizing manufacturing operations and achieving competitive advantages.

Factors Influencing the Effectiveness of Injection Tooling

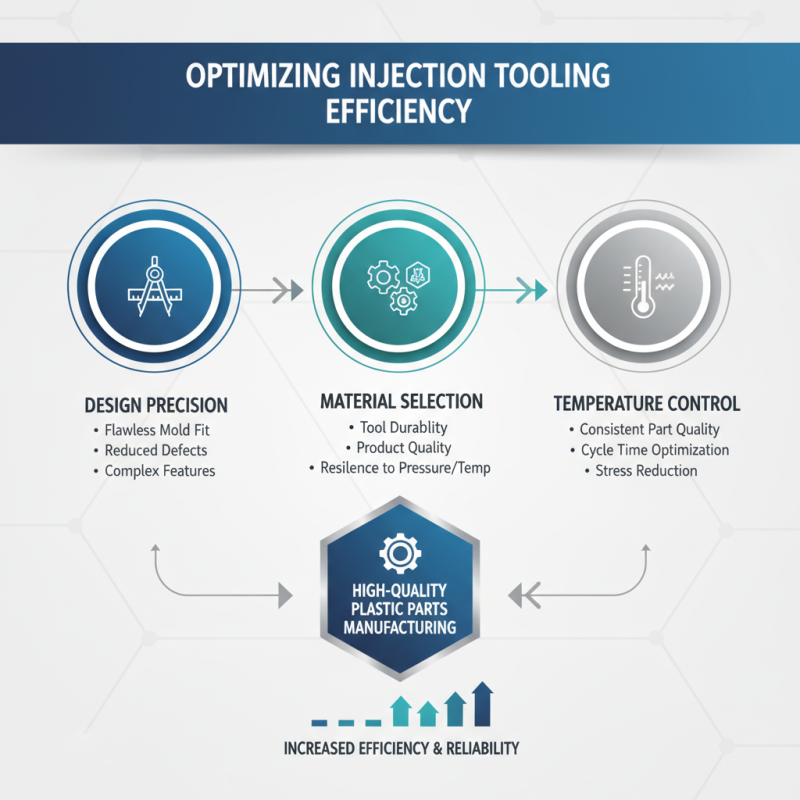

Injection tooling plays a crucial role in determining the efficiency of manufacturing processes, particularly in the production of high-quality plastic parts. Several factors significantly influence the effectiveness of injection tooling, including design precision, material selection, and temperature control. Precision in the design ensures that molds fit perfectly and have the necessary features, minimizing defects during production. Moreover, the choice of materials not only affects the durability of the tooling but also impacts the quality of the final product. High-quality materials can endure the intense pressure and temperature fluctuations experienced during the injection molding process, leading to more reliable outcomes.

Temperature control is another critical factor that affects the performance of injection tooling. Maintaining optimal temperatures during the injection phase ensures even distribution of the molten material, preventing inconsistencies and defects in the molded parts. Improper temperature management can lead to issues such as warping or incomplete filling, compromising the integrity of the finished product. Additionally, proper cooling channels integrated into the tooling can expedite cycle times and improve overall productivity, further enhancing manufacturing efficiency. Together, these factors underscore the importance of meticulous planning and execution in developing effective injection tooling, paving the way for streamlined production processes.

Future Trends in Injection Tooling and Manufacturing Efficiency

The landscape of injection tooling is rapidly evolving, driven by advancements in technology and an increasing demand for manufacturing efficiency. Future trends such as automation, the integration of artificial intelligence, and the use of sustainable materials are set to transform the injection molding process. These innovations not only streamline production but also reduce waste and energy consumption, making the process more environmentally friendly. Manufacturers are increasingly adopting smart tooling solutions that allow for real-time monitoring and adjustments, ensuring optimal performance and minimizing downtime.

Tip: Invest in software that enhances predictive maintenance capabilities, helping to identify potential issues before they disrupt production. This proactive approach can save time and costs in the long run.

Moreover, the shift towards customizable manufacturing solutions is gaining traction. As consumer preferences shift towards personalized products, injection molding techniques are adapting to meet these demands. Future tooling systems will enable rapid changes in designs without significant downtime, making it simpler for manufacturers to pivot based on market trends. The incorporation of modular tooling systems is another trend that supports versatility and efficiency, allowing manufacturers to respond swiftly to varying production needs.

Tip: Regularly evaluate and update tooling systems to stay aligned with the latest technologies. This can lead to improved production capabilities and greater flexibility to adapt to market changes.

Why Injection Tooling is Essential for Efficient Manufacturing Processes - Future Trends in Injection Tooling and Manufacturing Efficiency

| Aspect | Current Trends | Future Projections | Impact on Efficiency |

|---|---|---|---|

| Manufacturing Speed | Increased use of automation | 15%-20% faster production cycles | Higher throughput |

| Material Efficiency | Use of advanced polymers | Reduction of waste by 10%-15% | Cost savings |

| Tooling Technology | Adoption of 3D printing for molds | Further reduction in mold production time | Quicker time to market |

| Customization | Increased demand for tailored solutions | Greater flexibility with smaller batch sizes | Enhanced customer satisfaction |

| Sustainability | Focus on eco-friendly materials | Wider adoption of circular manufacturing | Reduced environmental impact |

Related Posts

-

How to Choose the Best Injection Molding Die for Your Production Needs: Insights from Industry Experts

-

China's Premier Plastic Injection Tooling Solutions for a Global Market

-

Exploring Unique Product Features and Applications in Best Plastic Injection Mold Tooling

-

How to Maximize Efficiency in Plastic Injection Molding: Strategies and Industry Insights

-

The Future of Injection Molding Mold Technologies Driving Efficiency and Sustainability in Manufacturing

-

Understanding the Role of Injection Molding Design in Sustainable Manufacturing