2025 How to Master Injection Mold Making for Efficient Production

Injection mold making is a crucial process in the manufacturing industry, enabling the mass production of various plastic components with precision and efficiency. As technologies evolve and market demands shift, mastering the art of injection mold making is vital for manufacturers seeking to remain competitive. In 2025, understanding the nuances of injection mold making will not only enhance productivity but also improve product quality, reduce waste, and lower production costs.

To excel in injection mold making, it is essential to grasp both the theoretical and practical aspects of the process. This involves not only selecting the right materials and tools but also implementing advanced techniques that streamline production workflows. By adopting best practices and embracing innovation in mold design and fabrication, manufacturers can achieve higher levels of efficiency and reliability in their production lines.

In this guide, we will explore key strategies and insights that can help professionals master injection mold making. From the importance of precision in mold design to the latest advancements in technology, we aim to provide a comprehensive overview that equips manufacturers with the knowledge required to enhance their production capabilities and achieve remarkable results in today's competitive landscape.

Understanding the Basics of Injection Mold Making Techniques

Injection mold making is a crucial process in the manufacturing industry, particularly in producing high-quality, precise plastic parts. Understanding the basics of injection mold making techniques is essential for anyone looking to master this art. The process begins with designing the mold, which involves careful consideration of the product's geometry and material properties. Effective mold design ensures that the final product will have the correct dimensions and surface finish, while also minimizing production costs.

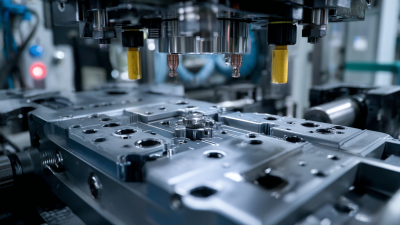

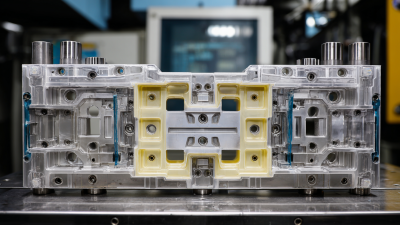

Once the design is finalized, the next step is to select the right materials for the mold itself. Commonly, steel and aluminum are chosen for their durability and resistance to wear. The chosen material also impacts the heat transfer characteristics of the mold, which is critical during the injection process. Following material selection, the mold is manufactured using advanced machining techniques that include milling, turning, and EDM (Electrical Discharge Machining). This phase requires precision and expertise to create the complex shapes and features needed for effective molding.

Finally, the injection molding process involves melting the plastic material and injecting it into the mold cavity. Factors such as temperature, pressure, and cycle time must be carefully controlled to achieve optimal results. Understanding how to adjust these parameters can vastly improve the efficiency of production and reduce waste. By mastering these fundamental techniques of injection mold making, manufacturers can ensure consistent quality, speed up production times, and ultimately enhance their overall competitiveness in the market.

Key Materials Used in Injection Mold Production for Enhanced Efficiency

In injection mold making, the choice of materials is critical for achieving enhanced efficiency in production. Recent industry reports indicate that the global injection molding market is projected to grow significantly, reaching over $300 billion by 2025. This growth emphasizes the importance of utilizing advanced materials that not only create high-quality molds but also optimize the manufacturing process. Steel, particularly tools such as P20 and H13, remains a popular choice for their durability and ability to withstand the high pressures of injection molding. P20 steel is renowned for its machinability, while H13 steel offers excellent heat resistance, making them ideal for various applications.

In addition to traditional metals, the incorporation of engineered plastics, such as polyetheretherketone (PEEK) and polyamide (PA), is on the rise. These materials provide substantial advantages in terms of weight reduction and corrosion resistance, which are crucial for extending mold life and maintaining production efficiency. According to a report by Research and Markets, the use of advanced materials in injection molding is expected to improve production speed by up to 15% and reduce downtime significantly. By embracing innovative material solutions, manufacturers can enhance their injection mold-making capabilities, leading to more efficient production workflows and lower operational costs.

Step-by-Step Process of Designing and Engineering Injection Molds

To master the process of injection mold making for efficient production, a solid grasp of designing and engineering injection molds is essential. The journey begins with understanding the requirements of the plastic part being produced. This step involves comprehensive collaboration with design engineers to ensure that the mold design aligns with the part specifications. The initial design should incorporate considerations for material flow, temperature control, and part cooling to optimize production efficiency.

Once the design parameters are defined, creating a detailed mold design using CAD software is the next step. This digital blueprint includes precise dimensions and specifications, allowing engineers to visualize the mold components. It’s crucial to include features that facilitate easy mold release and minimize defects. Additionally, simulations can be performed to predict how the molten material will fill the mold, identifying potential issues before physical production begins.

**Tips:** Always prioritize the mold's ease of maintenance in your design. This consideration can significantly reduce downtime during production. Furthermore, engaging in regular discussions with your tooling team can enhance the accuracy of the design and expedite the overall process. Lastly, keep an eye on advancements in mold-making technology; new tools and techniques can lead to even greater efficiency and cost-effectiveness in your projects.

2025 How to Master Injection Mold Making for Efficient Production - Step-by-Step Process of Designing and Engineering Injection Molds

| Step | Description | Key Considerations | Estimated Time (days) |

|---|---|---|---|

| 1 | Define Product Specifications | Material, dimensions, functionality | 5 |

| 2 | Create Initial Design Concepts | Sketches and CAD models | 7 |

| 3 | Run Simulations | Check for flow, cooling, and deformation | 3 |

| 4 | Finalize Mold Design | Include all specifications and adjustments | 10 |

| 5 | Select Materials for Molds | Durability, heat resistance, cost | 2 |

| 6 | Manufacture the Mold | CNC machining, finishing | 20 |

| 7 | Testing and Validation | Check the mold efficiency and durability | 5 |

| 8 | Production Setup | Organize production workflow | 4 |

| 9 | Mass Production | Production of final parts | Ongoing |

| 10 | Continuous Improvement | Review production efficiency regularly | Ongoing |

Best Practices for Maintaining Injection Molds for Optimal Performance

Maintaining injection molds is crucial for ensuring optimal performance and longevity in the production process. Regular inspection and cleaning of molds can prevent common issues like wear and contamination that could affect the quality of the final products. It is essential to implement a maintenance schedule that includes routine checks for any signs of damage, rust, or misalignment. Keeping molds well-maintained not only enhances production efficiency but also extends their usable life.

**Tips:** One effective practice is to utilize a dedicated cleaning solution paired with soft brushes to gently remove debris without scratching the mold surface. Additionally, using a protective lubricant can help minimize friction and wear during production runs.

Another vital aspect is temperature control. Keeping molds at a consistent temperature during operation aids in achieving uniform cooling and solidification of the materials used. This not only ensures better product quality but also prevents thermal stress that could lead to mold failure.

**Tips:** Invest in temperature monitoring equipment to keep track of mold temperatures and detect any anomalies early. Incorporating thermal insulation can also reduce heat loss, making the process more energy-efficient while safeguarding mold integrity.

2025 Injection Mold Maintenance Best Practices

Emerging Technologies Shaping the Future of Injection Mold Making

The landscape of injection mold making is evolving rapidly, driven by emerging technologies that enhance efficiency and precision in production. Technologies such as additive manufacturing, artificial intelligence, and advanced simulation tools are at the forefront, enabling manufacturers to streamline their processes and reduce waste. These advancements not only lower production costs but also improve the overall quality of molded products, setting new standards in the industry.

Tips for mastering injection mold making include staying updated with the latest technological trends. Engaging in continuous education through workshops and online courses can provide insights into new techniques and tools. Additionally, consider integrating simulation technologies into your workflow. This can help in predicting potential issues in mold design and production, leading to a smoother manufacturing process.

Another vital tip is to leverage data analytics. By collecting and analyzing data throughout the production cycle, manufacturers can identify bottlenecks and areas for improvement. This proactive approach allows for adjustments that can significantly enhance performance. Embracing these emerging technologies will be crucial for those aiming to excel in injection mold making and meet the increasing demands of the market.

Related Posts

-

How to Choose the Best Injection Molding Die for Your Production Needs: Insights from Industry Experts

-

China's Premier Plastic Injection Tooling Solutions for a Global Market

-

Exploring Unique Product Features and Applications in Best Plastic Injection Mold Tooling

-

Unwavering Quality from Trusted Chinese Manufacturers in Best Plastic Mold Solutions

-

Unlocking Efficiency: Benefits of Injection Molding Die in Modern Manufacturing

-

How to Master the Art of Injection Mold Making for Your Business Success