How to Master Injection Mold Making Techniques for Cost Effective Production

The demand for efficient and cost-effective production processes continues to drive innovation across various manufacturing sectors, with injection mold making standing out as a critical technique. According to the Plastics Industry Association, the injection molding sector alone is expected to see a compound annual growth rate of 5.5% through 2028, underscoring the importance of mastering its techniques to remain competitive. As companies look to optimize their production capabilities, the precision and efficiency gained from advanced injection mold making can significantly reduce operational costs while enhancing product quality.

Dr. Emily Carter, an expert in polymer science and injection mold making technologies, emphasizes the necessity of skill development in this arena: “Mastering the intricacies of injection mold making not only enhances production efficiency but can also lead to substantial financial savings for manufacturers.” With the right techniques in place, businesses can streamline their workflow, minimize waste, and improve their overall market responsiveness. As such, understanding the intricate methodologies involved in injection mold making is paramount for any company aiming to excel in today’s competitive landscape.

Understanding the Fundamentals of Injection Mold Making Techniques

Injection mold making is a critical process in the manufacturing industry, playing a vital role in producing high-quality plastic parts efficiently. Understanding the fundamentals of injection mold making techniques is essential for mastering cost-effective production. According to the Plastics Industry Association, the global injection molding market was valued at approximately $250 billion in 2022, with a projected annual growth rate of 3.5% from 2023 to 2030. This increasing demand underscores the importance of honing one's skills in this area to remain competitive.

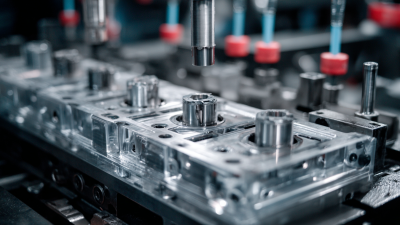

One fundamental technique in injection mold making involves mastering the design of molds that enhance efficiency and reduce cycle times. Factors such as gate design, runner configuration, and cooling channels can significantly impact production costs. It is vital to utilize simulation software to predict mold performance and identify potential issues before physical production begins. Additionally, implementing advanced materials in mold construction, like hardened steel or aluminum, can improve durability and reduce maintenance costs.

Tip: To optimize production, always consider the material properties of the plastic being molded, as they can affect cooling times and overall cycle duration.

Moreover, maintaining precision in machining and assembly processes is crucial. Adopting best practices in these areas not only ensures the quality of final products but also minimizes waste. According to a report by Markets and Markets, advancements in automation and smart manufacturing are expected to streamline mold making processes, enhancing productivity. This means that staying updated with technological trends and integrating them into your processes will be vital for achieving cost-effective production.

Tip: Regularly evaluate your workflow and consider lean manufacturing principles to eliminate unnecessary steps and enhance productivity.

Key Materials and Their Impact on Cost-Effective Mold Production

The choice of materials in injection mold making plays a crucial role in achieving cost-effective production while ensuring the quality and longevity of the molds. According to a recent report by the Plastics Industry Association, varying material selections can account for up to 30% of the overall production costs of injection molds. Common materials such as tool steels, aluminum, and unconventional polymers each offer unique advantages and drawbacks. For instance, tool steels, while offering high durability, come with increased initial investment compared to aluminum, which has a lower upfront cost but may compromise longevity in high-volume productions.

Additionally, the impact of material properties on the production process cannot be understated. A study published in the Journal of Manufacturing Science and Engineering highlights that the thermal conductivity of mold materials directly affects cycle times, with materials exhibiting higher thermal conductivity allowing for faster cooling and reduced production times. This increased efficiency can translate into significant cost savings, making the selection of the right materials not just a technical decision, but a strategic one that can enhance overall profitability. By considering both initial costs and the performance characteristics of different materials, manufacturers can optimize their injection molding processes and achieve a balance between quality and cost-effectiveness.

How to Master Injection Mold Making Techniques for Cost Effective Production - Key Materials and Their Impact on Cost-Effective Mold Production

| Material Type | Cost per kg ($) | Durability Rating | Production Speed (parts/hour) | Common Applications |

|---|---|---|---|---|

| Steel | 25 | High | 15 | Automotive Parts |

| Aluminum | 20 | Medium | 20 | Consumer Goods |

| Brass | 30 | Medium | 10 | Household Fixtures |

| Plastic (PP) | 2 | Low | 50 | Packaging |

| Plastic (ABS) | 3 | Medium | 30 | Toys & Housings |

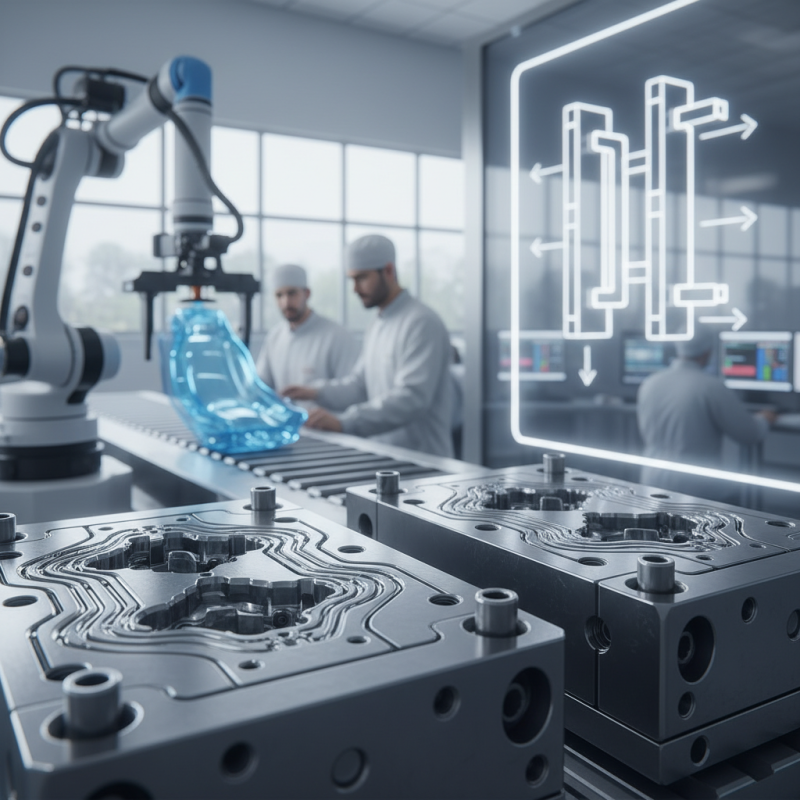

Essential Tools and Equipment for Efficient Injection Mold Making

Efficient injection mold making is critical for the success of production lines across various industries, particularly in automotive and consumer goods manufacturing. Essential tools and equipment play a vital role in achieving high-quality molds while keeping costs down. According to a recent report by the American Society of Mechanical Engineers, nearly 30% of production costs can be attributed to mold creation and maintenance. This highlights the need for investing strategically in reliable equipment such as CNC machining centers, EDM machines, and high-precision grinding tools.

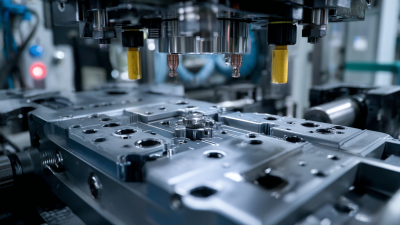

CNC machining centers provide the precision necessary for creating complex mold geometries quickly, which can significantly shorten production cycles. Additionally, Electric Discharge Machining (EDM) is indispensable when dealing with hard materials or intricate shapes that conventional machining struggles to produce effectively. While these tools require upfront investment, they lead to decreased production times and lower labor costs, ultimately enhancing the profitability of manufacturing operations.

Moreover, maintaining a well-equipped workshop with auxiliary tools like injection molding machines and temperature control units is equally important. Effective temperature management, as reported by the Society of Plastics Engineers, reduces cycle time by up to 20% while maintaining quality. This kind of efficiency is crucial in modern manufacturing environments, where staying competitive requires not just skilled labor, but also the right blend of technology and equipment. Investing in these essential tools can lead to significant improvements in both production quality and cost-effectiveness.

Step-by-Step Process of Designing and Fabricating Injection Molds

Designing and fabricating injection molds is a critical process that requires careful planning and execution to ensure cost-effective production. The first step in this process involves conceptualizing the mold design, which starts with a thorough understanding of the part requirements and material specifications. Designers often utilize Computer-Aided Design (CAD) software to create detailed 3D models of the mold, allowing for precise visualization and identification of potential issues in the design phase. Attention to factors such as draft angles, wall thickness, and even the type of gates and runners is essential to avoiding defects during the molding process.

Once the design is finalized, the next phase involves fabrication, which typically begins with selecting the right materials for the molds themselves. Common choices include steel and aluminum, each offering various benefits depending on production volume and cost considerations. After material selection, the actual machining process can commence, often involving CNC milling and electrical discharge machining (EDM) to achieve high precision. Throughout this phase, constant quality checks and adjustments may be necessary to maintain tolerances and ensure that the molds meet the required specifications. By following these detailed steps, manufacturers can effectively produce high-quality injection molds that facilitate efficient and economical production cycles.

Mastering Injection Mold Making Techniques: Production Cost Analysis

Quality Control Measures for Long-Lasting and Cost-Efficient Molds

Quality control measures are essential in the injection mold making process to ensure that the molds produced are durable and cost-efficient. According to a report by the Society of Plastics Engineers, approximately 60% of mold failures are attributed to inadequate design and insufficient quality control. Implementing stringent inspection techniques at every stage of production can significantly reduce these failure rates. For example, utilizing advanced imaging technologies, such as 3D laser scanning, allows manufacturers to identify precision issues early in the mold creation process, ensuring that molds meet the specified tolerances right from the start.

Furthermore, regular maintenance of injection molds not only prolongs their lifespan but also enhances performance efficiency. Studies have shown that proactive mold maintenance can lead to a reduction in operational costs by up to 25%. Quality control processes such as routine inspections, wear monitoring, and preventive repairs are crucial in maintaining mold effectiveness. By integrating these quality control measures, manufacturers can enhance their production capabilities, ensuring that molds are not only long-lasting but also yield high-quality products while keeping production costs manageable. Thus, an investment in robust quality control protocols can lead to significant cost savings and improved output for production facilities.

Related Posts

-

How to Optimize Your Injection Molding Tooling Processes for Maximum Efficiency

-

Exploring Unique Product Features and Applications in Best Plastic Injection Mold Tooling

-

Understanding the Role of Injection Molding Design in Sustainable Manufacturing

-

The Future of Best Plastic Injection Mold Design: Innovations Driving Global Manufacturing Growth

-

China's Premier Plastic Injection Tooling Solutions for a Global Market

-

Common Challenges in the Best Plastic Injection Moulding Process