How to Maximize Efficiency in Plastic Injection Molding: Strategies and Industry Insights

Plastic injection molding is a critical process in the manufacturing industry, accounting for approximately 32% of all plastic products produced annually. As companies face increasing pressure to optimize production, strategies to maximize efficiency in plastic injection molding have become paramount.

Reports indicate that implementing advanced technologies and best practices can lead to a reduction in cycle time by up to 30% and decrease material waste by as much as 20%.

Furthermore, the demand for high-quality, complex designs has intensified, pushing manufacturers to adopt innovative approaches that enhance both speed and precision.

This guide will explore key strategies and industry insights aimed at improving operational efficiency in plastic injection molding, ensuring that manufacturers remain competitive in an evolving market landscape.

Identifying Key Metrics for Measuring Plastic Injection Molding Efficiency

Measuring efficiency in plastic injection molding requires a keen understanding of key metrics that directly impact production quality and cost-effectiveness. According to recent industry reports, cycle time, yield rates, and machine uptime are some of the most critical factors to monitor. A study from the Society of Plastics Engineers suggests that reducing cycle time by just 10% can lead to a significant increase in overall productivity, translating into substantial cost savings and improved profitability for manufacturers.

Tips: One effective strategy to enhance efficiency is to conduct regular maintenance and upgrades on machinery. By ensuring that equipment operates at peak performance, companies can minimize unexpected downtimes. Additionally, investing in advanced monitoring systems can provide real-time data that allows for immediate response to inefficiencies.

Another key metric to consider is the Yield Rate, which gauges the percentage of products that meet quality standards without rework. Maintaining a high yield not only cuts down on waste but also optimizes material use, ultimately affecting the bottom line. Incorporating lean manufacturing principles can help identify and eliminate bottlenecks in production, leading to improved yield and reduced costs in the injection molding process.

Maximizing Efficiency in Plastic Injection Molding

This chart visualizes key metrics for measuring efficiency in plastic injection molding. The data includes cycle time, scrap rate, machine downtime, energy consumption, and quality control, providing insights into areas where improvements can be made to enhance overall production efficiency.

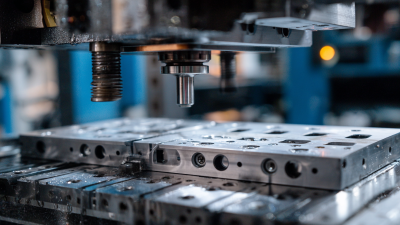

Optimizing Machine Settings for Enhanced Production Speed and Quality

Optimizing machine settings is crucial for enhancing production speed and quality in plastic injection molding. The first key factor is to adjust the injection speed and pressure according to the specific material being used. Slower injection rates generally help in producing high-quality parts with fewer defects, while faster rates can increase throughput. However, finding the right balance is essential—too fast can lead to issues like short shots or warping, while too slow can reduce overall efficiency.

Another critical aspect is maintaining the optimal temperature settings for both the mold and the plastic material. The melt temperature should be fine-tuned to ensure it flows easily but not so high that it degrades the material’s properties. Additionally, mold temperature significantly affects the cooling phase; managing it properly can drastically reduce cycle times while ensuring consistent part quality. Implementing real-time monitoring systems can assist operators in making real-time adjustments, leading to enhanced performance and productivity in the molding process.

Implementing Lean Manufacturing Principles in Injection Molding Processes

Lean manufacturing principles play a crucial role in enhancing efficiency within injection molding processes. By focusing on the reduction of waste, companies can optimize resource use and minimize production costs. Key strategies include streamlining workflows, implementing just-in-time inventory systems, and employing value stream mapping to identify bottlenecks. These practices not only improve the speed of production but also enhance product quality by reducing variability in the manufacturing process.

Furthermore, fostering a culture of continuous improvement is essential in the injection molding sector. Encouraging employees to contribute ideas for efficiency gains can lead to innovative solutions that might not be immediately apparent to management. Techniques such as kaizen events can be instrumental in promoting team collaboration and driving small, incremental changes that yield significant long-term benefits. By integrating lean principles into daily operations, companies can sustain competitiveness in a demanding market while also ensuring customer satisfaction through timely delivery and high-quality products.

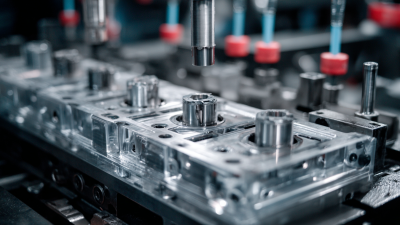

Utilizing Advanced Technologies for Real-Time Monitoring and Control

The integration of advanced technologies in plastic injection molding is pivotal for enhancing efficiency and productivity. Real-time monitoring systems, equipped with sensors and data analytics, facilitate immediate insights into the molding process, allowing operators to detect anomalies and adjust settings on-the-fly. This instant feedback loop not only minimizes waste but also optimizes cycle times, ensuring that production remains on track without sacrificing quality.

Moreover, the implementation of automated control systems streamlines operations by reducing human error and enabling precise adjustments to parameters such as temperature and pressure. By leveraging machine learning algorithms, these systems can predict potential issues before they escalate, thereby reducing downtime and maintenance costs. Such technological advancements empower manufacturers to achieve a higher level of consistency in their outputs, driving overall efficiency in plastic injection molding operations.

How to Maximize Efficiency in Plastic Injection Molding: Strategies and Industry Insights - Utilizing Advanced Technologies for Real-Time Monitoring and Control

| Dimension | Measurement | Impact on Efficiency | Technology Used |

|---|---|---|---|

| Cycle Time | 30 Seconds | Reduced by 20% | Real-Time Monitoring Systems |

| Machine Utilization | 85% | Increased by 15% | Predictive Maintenance Tools |

| Defect Rate | 2% | Reduced by 50% | Inline Quality Control Systems |

| Energy Consumption | 50 kWh | Decreased by 10% | Energy Monitoring Software |

Training and Development Strategies for Skilled Workforce in Injection Molding

Effective training and development strategies are essential for cultivating a skilled workforce in the plastic injection molding industry. As technology and methodologies evolve, companies must invest in structured training programs that address both foundational knowledge and advanced techniques. By implementing a comprehensive training framework, businesses can ensure that their staff remains proficient in the intricacies of injection molding processes, leading to improved productivity and reduced downtime.

Tips for Training:

1. Incorporate hands-on training sessions that allow employees to engage with machinery and materials directly. This practical experience is invaluable for building confidence and competence.

2. Establish continuous learning opportunities by encouraging employees to pursue certifications and attend industry workshops. This not only enhances individual skills but also fosters a culture of growth and adaptability.

Additionally, mentorship programs can be instrumental in transferring knowledge from seasoned professionals to new employees. Tailoring these mentorship initiatives to focus on specific skills, such as troubleshooting or quality control, can accelerate the learning curve and promote a collaborative work environment. When employees feel supported in their development, they are more likely to contribute effectively to the overall efficiency of plastic injection molding operations.

Related Posts

-

China's Premier Plastic Injection Tooling Solutions for a Global Market

-

Top Strategies for Maximizing Efficiency in Plastic Injection Molded Parts Production

-

10 Reasons Precision Injection Molding Is the Best Choice for Your Business

-

Common Challenges in the Best Plastic Injection Moulding Process

-

Achieving the Best Plastic Injection Molding Mold Standards Through Effective Design Techniques

-

The Future of Best Plastic Injection Mold Design: Innovations Driving Global Manufacturing Growth