Why is Plastic Injection Mold Tooling Essential for Effective Manufacturing

Plastic injection mold tooling is a critical component in the realm of effective manufacturing, serving as the backbone for producing high-quality plastic products with precision and efficiency. According to Dr. Emily Carter, a leading expert in the field of mold technology, “The quality of plastic injection mold tooling directly influences the output and performance of manufactured items.” This highlights the pivotal role that well-designed tooling plays in ensuring that production runs smoothly and cost-effectively.

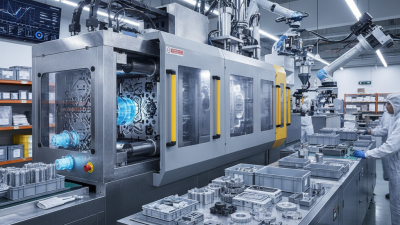

In the fast-paced world of manufacturing, efficiency and consistency are paramount. Plastic injection mold tooling not only reduces production times but also allows for the reproducibility of complex designs and details with minimal waste. As industries increasingly rely on automation and advanced technologies, the significance of sophisticated mold tooling has become even more pronounced. Leveraging the expertise of professionals like Dr. Carter emphasizes the necessity of investing in high-quality plastic injection mold tooling to stay competitive in the market.

Ultimately, the effectiveness of manufacturing processes significantly hinges on the standards of plastic injection mold tooling employed. By understanding its importance, manufacturers can better navigate challenges and seize opportunities for innovation, reaffirming plastic injection mold tooling as an essential element in the quest for excellence in production.

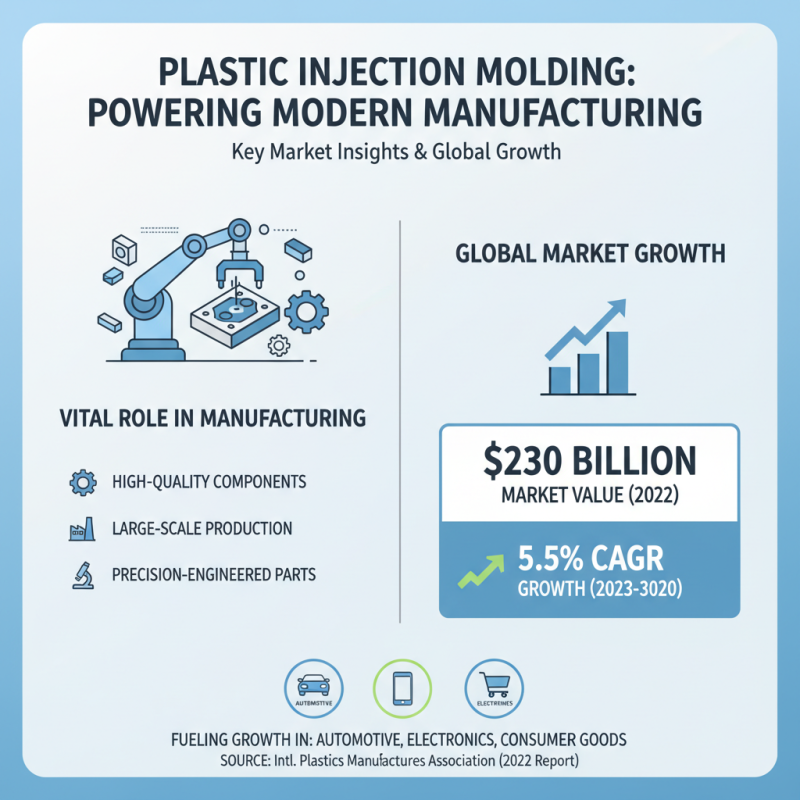

The Role of Plastic Injection Mold Tooling in Modern Manufacturing Practices

Plastic injection mold tooling plays a vital role in modern manufacturing practices, enabling companies to produce high-quality components at scale. According to a report by the International Plastics Manufacturers Association, the plastic injection molding market was valued at approximately $230 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.5% through 2030. This growth underscores the importance of advanced tooling technologies in meeting the increasing demand for precision-engineered plastic parts across various industries, including automotive, consumer goods, and electronics.

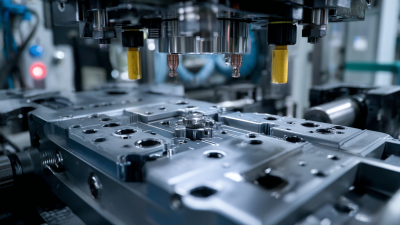

The efficiency of plastic injection mold tooling is further demonstrated by its ability to reduce production time and costs. By utilizing state-of-the-art technology, manufacturers can achieve cycle times as short as 15 seconds per part, drastically increasing throughput. This efficiency not only helps in optimizing resource utilization but also enhances overall productivity. In addition, the ability to create complex geometries with high repeatability makes injection molding a preferred choice for producing intricate components, which is essential in today’s competitive market where performance and quality standards are continuously rising. As outlined in a recent market analysis, organizations that invest in sophisticated injection mold tooling are positioned to capitalize on new opportunities, driving both innovation and profitability in their manufacturing processes.

Key Advantages of Plastic Injection Molding over Traditional Manufacturing Methods

Plastic injection molding has emerged as a preferred manufacturing method, offering several key advantages over traditional techniques. One of the most significant benefits is its efficiency. The process allows for rapid production, enabling manufacturers to create large quantities of parts with high repeatability. This scalability leads to reduced lead times, which is crucial in industries where speed to market is a competitive advantage. Furthermore, the ability to mold complex geometries in a single step can significantly decrease assembly requirements, streamlining production processes.

Another notable advantage of plastic injection molding is the consistency it provides in product quality. The precision of this method minimizes defects and variations in product dimensions, resulting in uniform outputs that meet stringent quality standards. This reliability is essential for industries such as automotive and medical, where even minor inconsistencies can lead to serious issues. Additionally, the use of advanced materials in plastic injection molding can enhance the durability and performance of the final products, making them suitable for a wide range of applications. Overall, these advantages highlight why plastic injection molding is a critical tool in modern manufacturing, driving efficiency and quality.

Industry Statistics: Impact of Effective Mold Tooling on Production Efficiency

Effective mold tooling is crucial in the plastic injection molding industry, as it directly influences production efficiency and quality. According to a report by the Society of the Plastics Industry (SPI), proper mold design and maintenance can enhance productivity by up to 30%. This statistic highlights the importance of investing in high-quality tooling processes, as inefficiencies in mold design can lead to increased cycle times, higher scrap rates, and ultimately, increased manufacturing costs.

Moreover, the American Injection Molding Institute (AIMI) states that properly executed mold tooling can reduce production downtime by 20% or more. This reduction is attributed to fewer mechanical failures and improved accuracy during the injection molding process. Additionally, accurate tooling ensures consistent part quality, leading to fewer reworks and customer complaints. Such improvements not only save time but also bolster the competitive edge of manufacturers in a fast-paced market, where persistent quality and efficiency are paramount for success.

Why is Plastic Injection Mold Tooling Essential for Effective Manufacturing - Industry Statistics

| Statistic | Value | Impact on Production Efficiency |

|---|---|---|

| Reduction in Cycle Time | 20% Faster | Higher output per hour |

| Improvement in Product Quality | 15% Defect Rate Reduction | Lower rework and scrap costs |

| Tooling Longevity | 50,000 Shots | Less frequent tool replacements |

| Initial Setup Cost Reduction | 30% Decrease | Lower barrier to entry for production |

| Energy Consumption | 25% Lower | Reduced operating costs |

Cost-Effectiveness of Plastic Injection Mold Tooling in Mass Production

Cost-effectiveness is one of the primary reasons why plastic injection mold tooling is indispensable in mass production. By utilizing this manufacturing technique, companies can achieve high output levels with minimal material waste. The precision of injection molding allows for the creation of complex shapes in a single shot, reducing the need for additional machining or assembly processes. This streamlined method not only saves labor costs but also shortens production cycles, enabling manufacturers to respond rapidly to market demands.

Moreover, the durability of injection molds contributes significantly to their cost-effectiveness. While the initial investment in high-quality molds may be substantial, their longevity results in lower per-piece costs over time. As molds are capable of producing thousands or even millions of parts, the amortization of the tooling expense becomes favorable as production scales up. This characteristic makes plastic injection mold tooling particularly appealing for industries requiring large volumes of consistent and high-quality parts, reaffirming its importance in modern manufacturing strategies.

Innovations in Mold Design: Enhancing Quality and Reducing Waste in Manufacturing

Innovations in mold design are transforming the landscape of plastic injection mold tooling, enhancing product quality while simultaneously driving down waste in manufacturing processes. Recent industry reports indicate that advancements such as conformal cooling and lightweight mold materials can significantly improve thermal management within the mold, thereby reducing cycle times by up to 30%. For instance, employing modern simulation techniques enables manufacturers to predict and resolve potential defects before production even begins, leading to improved precision and fewer rejected parts.

Moreover, the integration of sustainable practices in mold design, such as the use of biodegradable materials and energy-efficient processes, aligns with global trends towards sustainability in manufacturing. According to a recent study by the American Society of Mechanical Engineers (ASME), manufacturers adopting intelligent mold designs report a waste reduction of as much as 40%, which not only lowers costs but also minimizes environmental impact. By focusing on innovative mold design techniques, manufacturers can enjoy both enhanced operational efficiency and a stronger commitment to sustainability, setting the stage for future growth in the competitive landscape of plastic injection molding.

Plastic Injection Mold Tooling Efficiency Metrics

Related Posts

-

How to Choose the Best Injection Molding Die for Your Production Needs: Insights from Industry Experts

-

Why Injection Tooling is Essential for Efficient Manufacturing Processes

-

Exploring Unique Product Features and Applications in Best Plastic Injection Mold Tooling

-

Common Challenges in the Best Plastic Injection Moulding Process

-

The Future of Injection Molding Mold Technologies Driving Efficiency and Sustainability in Manufacturing

-

2025 How to Master Injection Mold Making for Efficient Production