Why Is Plastic Injection Tooling Essential for Manufacturing?

In the manufacturing sector, the importance of plastic injection tooling is undeniable. According to John Smith, an expert in the field, "Plastic injection tooling is the backbone of efficient production." This process shapes raw plastic into products we use daily. Without it, many industries would struggle to create reliable goods.

Plastic injection tooling offers precision and speed. However, challenges exist. Many manufacturers face difficulties in tool design and maintenance. These issues can lead to delays and increased costs. In the fast-paced market, it's crucial for companies to adapt quickly. Yet, not all organizations invest in advanced tooling technologies. This can limit their competitiveness.

The future of manufacturing relies on efficient plastic injection tooling. Investing in quality tools is vital. A robust tool can enhance production efficiency significantly. Companies should constantly evaluate their tooling strategies. Only then can they meet the growing demands of consumers effectively.

The Definition and Overview of Plastic Injection Tooling

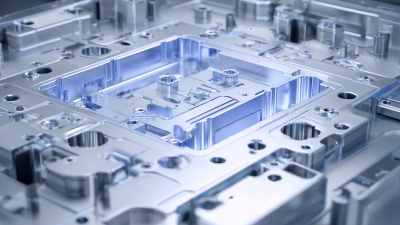

Plastic injection tooling is a critical component in the manufacturing process. It involves creating molds used for producing plastic parts. This method allows for high-volume production with precision and consistency. According to industry reports, about 29% of the plastic products manufactured globally utilize injection molding. This statistic underscores its significance in various sectors, including automotive, consumer goods, and medical devices.

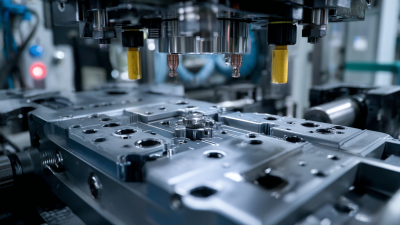

The process itself requires specialized knowledge and technology. Designers must consider factors like material type, part geometry, and production volume. Each mold must be crafted meticulously to ensure it can withstand the high pressure and temperature of injection processes. However, the initial investment in tooling can be substantial, leading to some hesitance among manufacturers.

Furthermore, maintaining molds is crucial for consistent production quality. Frequent checks and repairs are necessary to avoid defects. Some companies report downtime due to mold maintenance, which can be costly. Continuous improvement is essential, and innovations in tooling technologies are advancing rapidly. Manufacturers who adapt to these changes often gain a competitive edge, yet the constant evolution can be overwhelming. Balancing investment in new technologies and maintaining existing tools remains a challenge.

Importance of Plastic Injection Tooling in Manufacturing

The Role of Plastic Injection Tooling in the Manufacturing Process

Plastic injection tooling plays a critical role in the manufacturing process. This method allows companies to produce complex parts with precision. According to a report by the American Society for Quality, 60% of manufacturers rank consistency in part quality as a top priority. Injection molding helps achieve this by utilizing hardened steel molds to maintain shape and dimensions.

Molds can be costly, often ranging from $5,000 to $100,000 depending on complexity. Many companies struggle with initial investment decisions. A lack of quality tooling can lead to higher defect rates and increased waste. Reports indicate that poor tooling can result in up to 20% scrap rates in production. This not only affects profitability but also impacts sustainability efforts.

Moreover, the speed of production is vital. Injection molding can produce thousands of parts per hour. However, delays in tooling design can slow down the overall process. Teams must reflect on their tooling choices regularly. Striking the right balance between cost and output is essential. It's a challenging yet necessary aspect of manufacturing today, where efficiency is paramount.

Key Advantages of Using Plastic Injection Tooling

Plastic injection tooling plays a crucial role in manufacturing across various industries. One of its key advantages is efficiency. The process allows for rapid production of complex parts. Such efficiency translates to reduced lead times. Manufacturers can quickly meet market demands. This advantage often leads to cost savings over time.

Another benefit is the ability to create intricate designs. This tooling method enables high precision and detail. Features like fine textures and tight tolerances are easily achievable. However, achieving this level of detail requires skilled operators and careful planning. Mistakes in the design phase can lead to wasted materials and time.

Durability is also noteworthy. Parts created through injection molding are generally strong and long-lasting. They can withstand various environmental conditions. However, relying solely on this method might overlook other innovative solutions. Companies should reflect on the full range of manufacturing techniques available. It’s crucial to weigh the pros and cons as technology evolves.

Common Applications of Plastic Injection Tooling in Industries

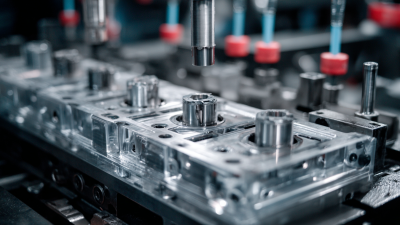

Plastic injection tooling plays a vital role across various industries. This method allows for the mass production of high-quality plastic parts. In automotive manufacturing, for instance, it creates essential components like dashboard panels and bumpers. Each piece is designed for durability and precision. However, achieving the perfect mold can be challenging. Minor deviations may lead to costly errors in production.

Consumer electronics also benefit from this technology. Companies use plastic injection tooling for producing housings and internal parts of devices. These need to fit perfectly, balancing aesthetics and function. Yet, there is a continuous need for improvement. Sometimes, the molds wear out quickly, resulting in changes in product quality. Regular maintenance and updates are crucial.

In medical devices, precision is paramount. Plastic parts must meet strict regulatory standards. Injection tooling enables the production of intricate designs. However, the risk of contamination during the process is a serious concern. Manufacturers must remain vigilant at all times.

Efficient plastic injection tooling serves as a backbone for efficient production across industries, yet it requires constant attention and refinement.

Future Trends and Innovations in Plastic Injection Tooling

Plastic injection tooling is witnessing exciting advancements in recent years. Industry reports suggest that this market is projected to grow at a compound annual growth rate (CAGR) of 4.9% through 2025. Companies are investing in automation and advanced materials to enhance efficiency and reduce costs.

Emerging trends include the integration of 3D printing with injection tooling. This method allows rapid prototyping of complex designs. It can shorten production cycles significantly. Additionally, the focus on sustainability is reshaping the industry. More manufacturers are opting for biodegradable materials. This shift aligns with global efforts to reduce plastic waste.

Tips: Consider adopting hybrid methods combining traditional tooling with modern technologies. This can enhance flexibility and innovation. Embracing a design-thinking approach may help address production challenges effectively. Remember, continuous learning is vital. Stay updated on material innovations and market needs.

Related Posts

-

How to Master Injection Mold Making Techniques for Cost Effective Production

-

Exploring Unique Product Features and Applications in Best Plastic Injection Mold Tooling

-

Innovative Injection Molding Design Examples to Inspire Your Next Project

-

The Future of Best Plastic Injection Mold Design: Innovations Driving Global Manufacturing Growth

-

China's Premier Plastic Injection Tooling Solutions for a Global Market

-

Unlocking Efficiency: Benefits of Injection Molding Die in Modern Manufacturing