Top 10 Benefits of Polyethylene Injection Molding You Should Know?

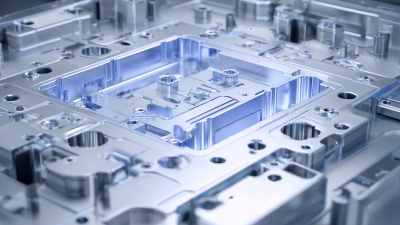

Polyethylene injection molding is a key process in manufacturing. This method offers numerous advantages that enhance efficiency and product quality. With a diverse range of applications, industries increasingly rely on polyethylene for its durability and versatility.

One significant benefit of polyethylene injection molding is cost-effectiveness. It allows for mass production with minimal wasted materials. The speed of this process increases output, saving both time and resources. Additionally, it enables manufacturers to create intricate designs with precision. Many businesses appreciate the reliability of molds created from polyethylene.

However, challenges can arise with this process. The setup costs may be high for small batches. There are also limitations on the types of finishes achievable with polyethylene. Still, the positive aspects often outweigh the negatives. Understanding these benefits can lead to better decision-making in production. Embracing polyethylene injection molding opens doors to innovation and efficiency in manufacturing.

Key Advantages of Polyethylene in Injection Molding Processes

Polyethylene is a popular choice for injection molding due to several key advantages. It is lightweight yet durable, making it suitable for various applications. Its resistance to chemicals and moisture is impressive. This property is especially beneficial in industries where exposure to harsh substances is common. Moreover, polyethylene can withstand temperature fluctuations without losing its integrity.

Tips: When selecting polyethylene for your project, consider the required thickness. Thinner materials can be more flexible but may lack strength. Additionally, test for compatibility with your specific application.

Another significant advantage is the ease of processing. Polyethylene can be molded into complex shapes with precision. This flexibility allows for innovative designs that meet specific requirements. The cost-effectiveness of polyethylene is also noteworthy. It is relatively inexpensive compared to many other materials.

Tips: Remember to evaluate your production volume. High volumes can lower the overall costs further. It’s also essential to review recycling options. Polyethylene is largely recyclable, which adds to its sustainability.

Cost-Effectiveness of Polyethylene Injection Molding for Manufacturing

Polyethylene injection molding offers significant cost-effectiveness in manufacturing. This technique utilizes raw materials efficiently, resulting in less waste. Manufacturers can produce high volumes of plastic parts at a lower per-unit cost. Labor costs are also reduced with automated processes. It’s a win-win scenario for production efficiency and budget management.

When considering polyethylene injection molding, keep an eye on the production cycle. Short cycle times can lead to increased output. However, ensure that quality is not compromised. Sometimes, a rush can result in defects, which can be costly in the long run. It’s important to balance speed and quality for optimal results.

Investing in the right machinery is critical. Quality machines enhance speed and precision, which ultimately cut costs. Yet, heavy upfront investments can be a concern. It’s wise to analyze long-term savings versus initial expenses. Consider growth plans; they can help justify these investments.

Top 10 Benefits of Polyethylene Injection Molding

Versatility of Polyethylene: Applications Across Various Industries

Polyethylene is widely recognized for its versatility in the manufacturing world. It is used in various industries, including packaging, automotive, and medical applications. The lightweight nature of polyethylene makes it ideal for creating containers that hold everything from chemicals to food items. Its chemical resistance ensures that products remain safe and intact.

In the automotive industry, polyethylene is found in various components, from fuel tanks to bumpers. Its durability under extreme conditions makes it a popular choice. However, there are concerns with its environmental impact. Recycling options exist, but not all polyethylene products are recycled effectively. This raises important questions about sustainability.

Medical applications also benefit from polyethylene. Items such as syringes and medical bags are frequently made from this material. Its ability to be sterilized adds to its appeal. Yet, the reliance on single-use plastics in healthcare poses challenges for reducing medical waste. Balancing utility and environmental responsibility remains a key issue in polyethylene injection molding.

Environmental Impact and Sustainability of Polyethylene Materials

Polyethylene materials play a significant role in modern manufacturing. Their lightweight and durable nature makes them an attractive option for various applications. However, the environmental impact of polyethylene is complex. Production and disposal can lead to pollution. This creates a pressing need for more sustainable methods.

Recycling polyethylene is one way to mitigate its environmental footprint. Many facilities now focus on reprocessing scrap material. This reduces waste and helps conserve resources. However, the recycling process itself is not perfect. Sometimes, contamination occurs, diminishing the material's quality. Not all polyethylene products are recyclable, leading to further challenges.

Alternatives to traditional polyethylene are emerging. Biodegradable materials are gaining traction. They offer potential solutions but come with their own set of issues, such as cost and performance concerns. Consumers and manufacturers alike must consider these factors. Sustainable practices are not just a trend; they are a necessity for the future.

Improved Product Performance Through Enhanced Design Flexibility

Polyethylene injection molding is gaining traction for its design flexibility. It allows manufacturers to create complex shapes and intricate features. This freedom leads to innovative product designs that were once challenging to achieve. The ability to mold thin walls or detailed textures opens doors for creativity. Designers can experiment with variations, adjusting sizes and features easily.

Moreover, the enhanced design capability improves product performance. Products can be engineered to meet specific functional requirements while maintaining an appealing aesthetic. With customization options, companies can cater to unique market demands. However, the complexity of the process may pose challenges. Balancing design intricacies with production efficiency requires careful planning. Mistakes in design could lead to increased costs and delays.

Despite potential pitfalls, the benefits are significant. Enhanced design flexibility can lead to superior product offerings. Manufacturers can innovate while addressing consumer needs. Embracing this technology can provide a competitive edge. Yet, it's essential to continually assess and refine processes to ensure sustained success.

Related Posts

-

The Ultimate Guide to Mastering Best Polyethylene Injection Molding Techniques

-

Unlocking Efficiency: Benefits of Injection Molding Die in Modern Manufacturing

-

Innovative Injection Molding Design Examples to Inspire Your Next Project

-

The Future of Injection Molding Mold Technologies Driving Efficiency and Sustainability in Manufacturing

-

Unlocking the Advantages of Best Injection Tooling in Modern Manufacturing Processes

-

2025 Top Injection Molding Die Innovations: Shaping the Future of Manufacturing