2025 Top 5 Innovations in Plastic Mold Design You Should Know

In the fast-evolving world of manufacturing, plastic mold design plays a critical role in ensuring efficiency, durability, and innovation in production processes. According to a recent report by Smithers Pira, the global market for plastic mold design is projected to reach $33 billion by 2025, driven by advancements in technology and increasing demand across industries. As companies strive for higher productivity and lower costs, understanding the latest innovations in plastic mold design becomes vital for maintaining a competitive edge.

Leading experts emphasize the importance of staying abreast of new developments in this field. Dr. Emily Harris, a renowned authority in plastic engineering, asserts, "The future of plastic mold design is not just about improving current processes but also about embracing smart technologies that can revolutionize how we design and manufacture." This sentiment reflects the industry’s shift towards incorporating automation, simulation software, and sustainable materials in mold design, which are expected to dominate trends in the coming years.

As we delve into the top five innovations shaping the trajectory of plastic mold design, it is essential to consider their potential impact on manufacturing efficiency and product quality. From enhanced cooling systems to advanced mold materials, these innovations are set to redefine the capabilities of plastic mold manufacturing, offering businesses new avenues for growth and enhanced performance.

Emerging Trends in 3D Printing for Enhanced Mold Design Efficiency

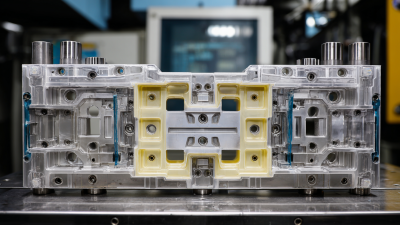

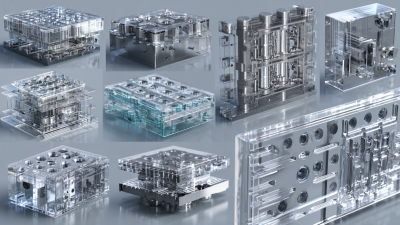

The landscape of plastic mold design is rapidly evolving, driven by innovations in 3D printing technology. One of the most significant emerging trends is the use of additive manufacturing techniques to produce molds more rapidly and with greater precision than traditional methods. By utilizing 3D printing, designers can create complex geometries and intricate designs that would be extremely difficult or impossible to achieve through conventional machining. This not only allows for greater creativity in design but also reduces lead times dramatically, enabling quicker prototyping and testing.

Another trend is the integration of smart technologies into mold design, such as sensors and IoT capabilities. These innovations allow for real-time monitoring and data collection during the molding process, leading to improved efficiency, reduced waste, and better quality control. By harnessing the power of 3D printing alongside smart technologies, manufacturers can create molds that are not only lightweight but also more effective in terms of thermal management and durability. This convergence of innovations is setting the stage for the next generation of mold design, making it essential for industry professionals to stay updated on these advancements.

Leveraging AI for Predictive Maintenance in Plastic Molding Processes

As the plastic molding industry evolves, leveraging artificial intelligence (AI) for predictive maintenance is becoming a pivotal innovation. In 2025, the global hot runner market is projected to reach approximately 4609.06 million, expanding to about 9822.22 million by 2033, showcasing a compound annual growth rate (CAGR) of 9.92%. This growth highlights the increasing need for efficiency and reliability in manufacturing processes.

By implementing AI-driven predictive maintenance, companies can analyze data in real-time to predict equipment failures before they occur. This proactive approach not only minimizes downtime but also extends the lifespan of machinery, resulting in significant cost savings. As the industry moves toward automation and smart technologies, the integration of AI will be critical for enhancing production outcomes and maintaining a competitive edge.

**Tips:** Regularly train your machines with AI algorithms to ensure accurate predictive analytics. Additionally, consider investing in IoT sensors that provide real-time data feedback, enabling swift adjustments to your molding processes. Embracing these innovations can position your business at the forefront of the plastic molding revolution.

2025 Top 5 Innovations in Plastic Mold Design You Should Know

| Innovation | Description | Benefits | Implementation Status |

|---|---|---|---|

| AI-Driven Predictive Maintenance | Utilizing AI algorithms to predict equipment failures before they occur. | Reduced downtime, lower maintenance costs, increased productivity. | Ongoing trials in select manufacturing plants. |

| 3D Printing for Mold Prototyping | Rapid prototyping of molds using advanced 3D printing technology. | Faster design iterations, reduced material waste, lower costs. | Widely adopted across various sectors. |

| Smart Sensors Integration | Integration of smart sensors to monitor the molding process in real-time. | Improved quality control, real-time adjustments, data-driven decisions. | In production with several leading manufacturers. |

| Material Innovations | Development of new, eco-friendly materials for plastic molds. | Sustainability, enhanced performance properties, market differentiation. | Currently in R&D and pilot testing phases. |

| Augmented Reality for Design Validation | Using AR to visualize and validate mold designs before production. | Enhanced design accuracy, reduced errors, faster approval processes. | Being introduced in design teams for ongoing projects. |

Sustainable Materials: Innovations in Eco-Friendly Mold Design Solutions

The shift towards sustainability in plastic mold design is becoming increasingly critical as industries seek eco-friendly solutions. A recent report projects that the global in-mold labels market will grow from USD 2.57 billion in 2026, indicating a rising demand for sustainable packaging solutions. This aligns with the increasing consumer awareness about environmental issues, particularly in the cosmetic sector, where eco-friendly packaging is now a significant purchasing factor.

Innovations like low-pressure injection molding are leading the way in sustainable plastics manufacturing, offering companies a way to reduce waste and improve efficiency. Alongside advancements in material science, these practices are driving a more sustainable future for production processes. The call for a ban on single-use plastics underscores the importance of transitioning towards sustainable materials, with experts emphasizing the substantial promise the sustainable packaging sector holds for both industries and the environment. As the landscape continues to evolve, staying informed about these innovations in mold design will be crucial for companies aiming to meet new market demands.

2025 Innovations in Eco-Friendly Mold Design Solutions

This chart illustrates the adoption rates of innovative eco-friendly materials in plastic mold design. The data reflects advancements in sustainable practices and the increasing use of biodegradable and recycled materials in the industry.

Smart Simulation Tools Transforming Prototype Testing in Mold Creation

The landscape of mold design is undergoing a transformative shift, driven largely by advancements in smart simulation tools. As the global simulation software market is poised to grow significantly, from $15.00 billion in 2025 to $33.62 billion by 2032, manufacturers are increasingly adopting these innovative technologies. These tools enable in-depth prototype testing that enhances the design process, allowing for quicker iterations and more efficient production cycles.

One notable development in this field is the integration of digital prototyping software, which accelerates the design phase by allowing engineers to create detailed 2D and 3D models. This technology facilitates early detection of potential design flaws, thus reducing the time and resources spent on physical prototypes. Additionally, the rise of digital twin technology exemplifies how virtual models can mirror their physical counterparts, enabling real-time analysis and optimization during the mold creation process. This synergy of simulation and practical application embodies the future of manufacturing, where flexibility and precision are paramount.

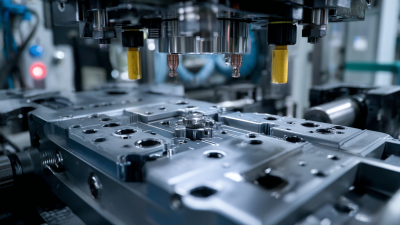

Integration of IoT Devices for Real-Time Monitoring of Mold Performance

The integration of IoT devices in plastic mold design is poised to revolutionize the manufacturing landscape by enabling real-time monitoring of mold performance. As the IoT in manufacturing market is projected to grow significantly, reaching a valuation of $141.18 billion in 2025, companies are increasingly leveraging these technologies to optimize their production processes. Real-time data sharing allows for proactive maintenance, reducing downtime and improving overall efficiency.

In this evolution, the application of IoT extends to various sectors, including agricultural machinery, where over 70% of new tractors now come equipped with IoT connectivity. This trend mirrors the wider manufacturing sector, showcasing how smart technology leads to enhanced diagnostics and operational efficiency. By adopting IoT solutions, manufacturers can attain unprecedented insights into their molds’ performance, facilitating a shift towards smarter, more connected factories. This transformation not only streamlines production but also paves the way for innovation in mold design and functionality.

Related Posts

-

Unwavering Quality from Trusted Chinese Manufacturers in Best Plastic Mold Solutions

-

Top 10 Essential Tips for Mastering Plastic Mold Design Techniques

-

China's Premier Plastic Injection Tooling Solutions for a Global Market

-

Exploring Unique Product Features and Applications in Best Plastic Injection Mold Tooling

-

How to Choose the Best Injection Molding Die for Your Production Needs: Insights from Industry Experts

-

Exploring the Future: How Plastic Injection Molding Shapes a $300 Billion Industry