Unwavering Quality from Trusted Chinese Manufacturers in Best Plastic Mold Solutions

In the ever-evolving landscape of manufacturing, the demand for high-quality plastic mold solutions continues to rise, driven by an estimated global plastic production of over 370 million metric tons in 2021, as reported by industry analysts. As industries across automotive, consumer goods, and electronics increasingly rely on precision-engineered components, trusted Chinese manufacturers have emerged as leaders in delivering unwavering quality in plastic mold fabrication. According to a recent market analysis from MarketsandMarkets, the plastic mold market is projected to grow from $25.4 billion in 2020 to $35.1 billion by 2025, underscoring the critical role well-engineered molds play in enhancing production efficiency and product quality. With an emphasis on innovation and efficiency, this blog will explore how the best practices from reputable Chinese manufacturers can provide tailored solutions that meet diverse industrial needs, establishing a benchmark for excellence in plastic mold technology.

The Importance of Selecting Reliable Chinese Manufacturers for Plastic Molds

When it comes to selecting plastic molds, the importance of partnering with reliable Chinese manufacturers cannot be overstated. China has established itself as a global leader in the plastic manufacturing sector, offering a vast array of mold solutions that meet industry standards. However, the key to success lies in choosing manufacturers who prioritize quality, precision, and transparency in their processes. This ensures that the end products not only meet specific requirements but also withstand time and usage.

Reliable Chinese manufacturers bring a wealth of experience and innovative technology to the table, making them invaluable partners in production. Their understanding of the latest market trends and manufacturing techniques allows them to create molds that are not only efficient but also cost-effective. Moreover, they often provide comprehensive support throughout the design and production phases, ensuring that clients receive tailored solutions that align with their needs.

By selecting trustworthy manufacturers, businesses can mitigate risks and enhance their supply chain efficiency, ultimately leading to better product outcomes and customer satisfaction.

Key Factors to Consider When Choosing Plastic Mold Solutions

When selecting plastic mold solutions, it’s essential to consider several key factors that can significantly impact the quality and efficiency of your manufacturing process. First and foremost, assess the manufacturer’s reputation. Trusted Chinese manufacturers often have a track record of delivering high-quality products. Researching their past projects and customer reviews can provide valuable insights into their reliability and craftsmanship.

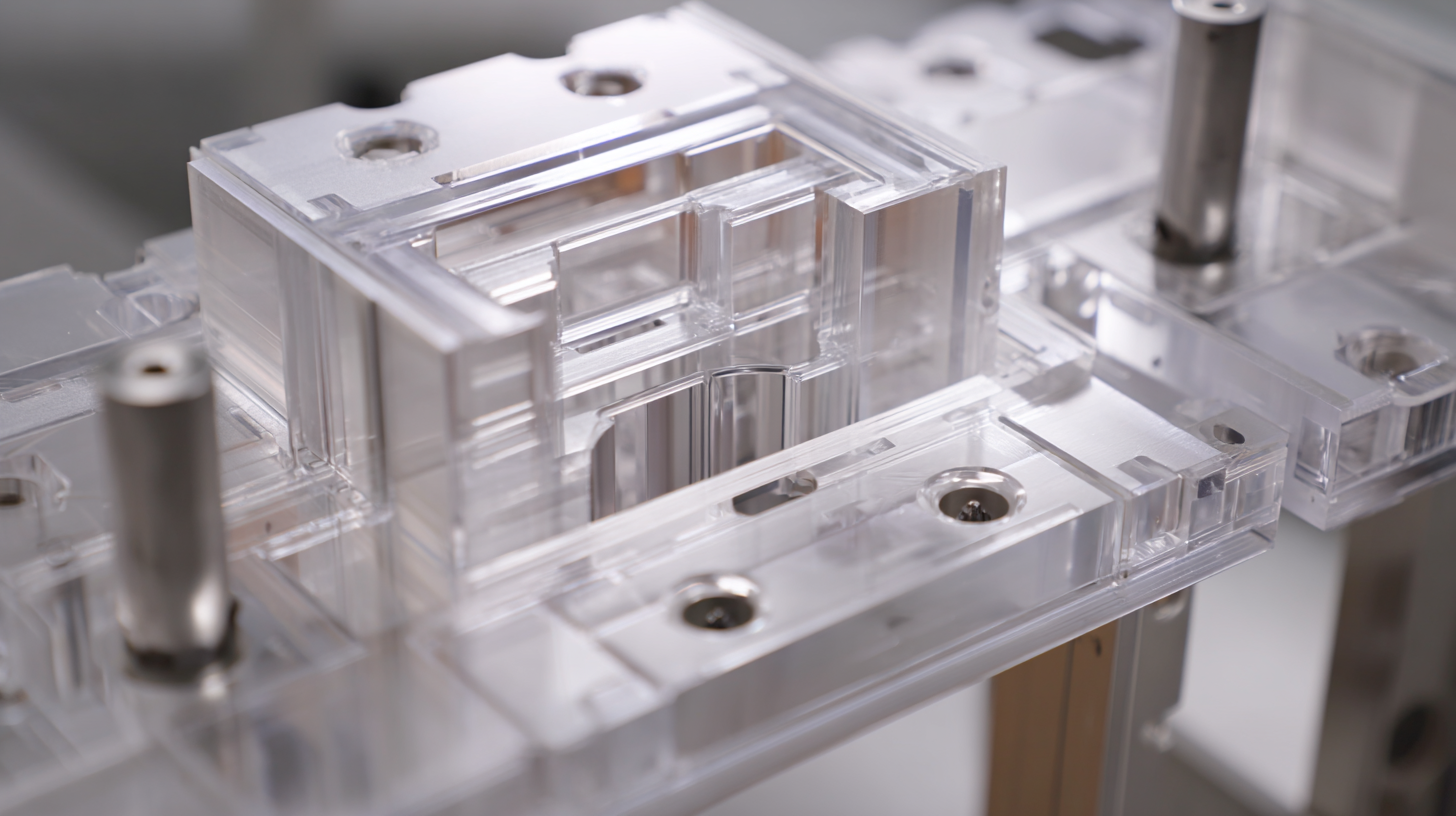

Additionally, you should focus on the technology and expertise employed by the manufacturer. State-of-the-art machinery and skilled technicians are crucial for producing precision molds. Invest time in understanding the materials used, as high-quality raw materials lead to durable and effective molds.

**Tip:** Always request samples or prototypes before making a large order. This will give you a firsthand look at the quality of the molds and help you gauge the manufacturer's capabilities.

Another factor to keep in mind is customer support. A manufacturer that offers solid after-sales service can guide you through any potential issues and ensure that your production runs smoothly. Clear communication and responsiveness are key indicators of a manufacturer that values their clients.

**Tip:** Establish a detailed communication plan from the outset, outlining expectations and timelines, to minimize misunderstandings and ensure a successful partnership.

Innovative Technologies in Chinese Manufacturing for Superior Mold Quality

In today's competitive landscape, the role of innovative technologies in enhancing manufacturing quality cannot be overstated.

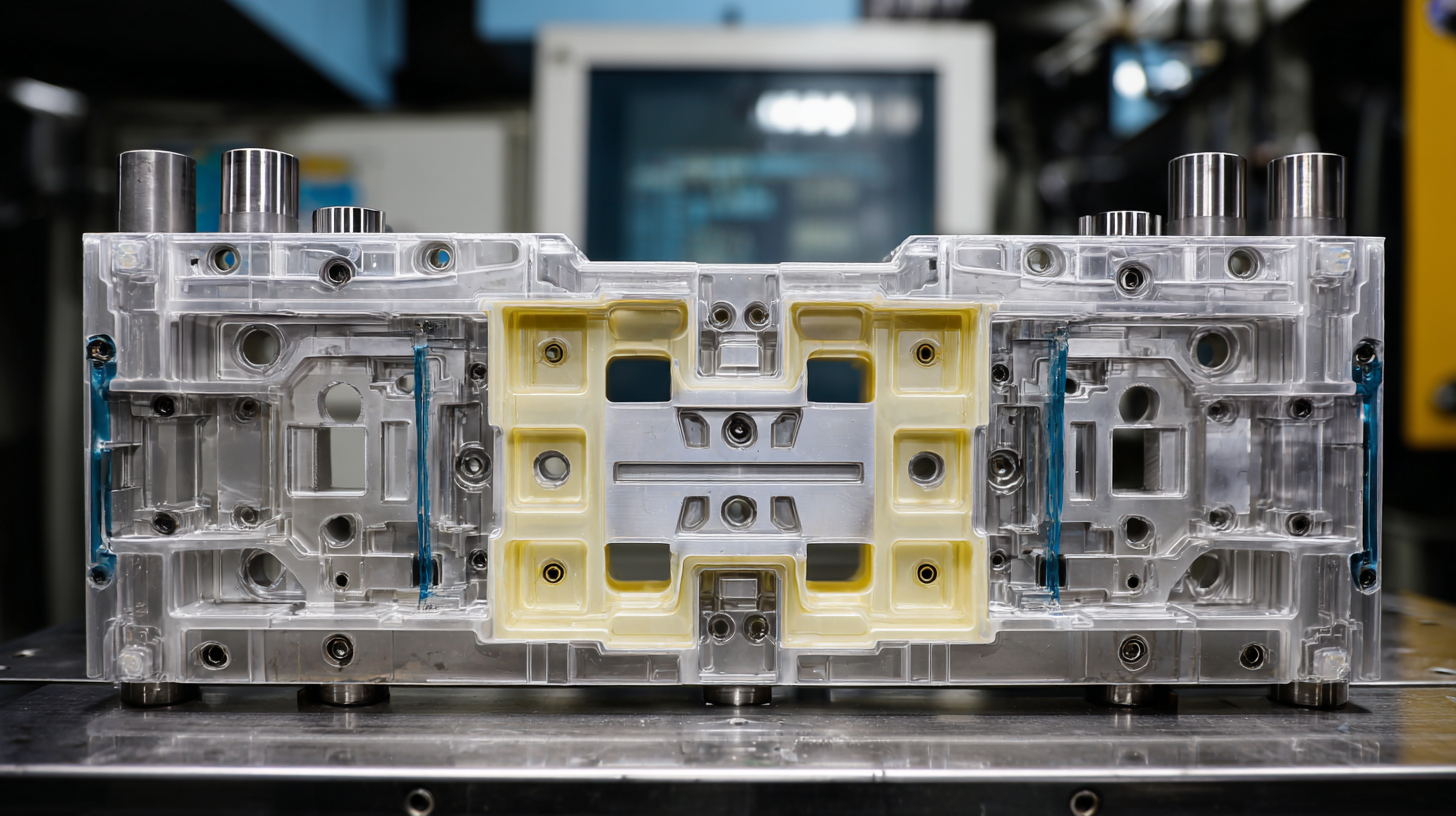

Chinese manufacturers have strategically integrated advanced technologies such as

automation,

3D printing, and

artificial intelligence

into their processes, revolutionizing the production of plastic molds.

These innovations enable manufacturers to streamline operations, reduce human errors, and maximize efficiency, leading to the creation of superior mold quality that meets global standards.

Moreover, the adoption of smart manufacturing techniques allows for precise customization and rapid prototyping, catering to the specific needs of diverse industries. Manufacturers can simulate mold designs in a virtual environment before actual production, significantly shortening lead times and minimizing material waste.

This commitment to incorporating cutting-edge technologies not only reinforces the reliability of Chinese manufacturers but also positions them as leaders in providing high-quality plastic mold solutions to markets worldwide.

As a result, businesses can trust that their production needs are met with unwavering quality and excellence.

Steps to Ensure Consistent Quality in Plastic Mold Production

In the competitive landscape of plastic mold production, maintaining consistent quality is paramount for success. Leading Chinese manufacturers leverage advanced technologies and stringent quality control measures to deliver reliable mold solutions. A study by MarketsandMarkets indicates that the global plastic mold market is projected to reach $37.5 billion by 2027, highlighting the growing demand for high-quality production. To meet this demand, manufacturers must adopt a systematic approach to quality assurance throughout the production process.

One vital step is the implementation of a robust quality management system (QMS), which ensures that every phase of production adheres to specific standards. Regular audits and inspections are crucial in identifying potential discrepancies early in the fabrication process. According to a report by Grand View Research, companies that prioritize quality management experience 20% fewer defects compared to their competitors.

**Tips:**

- Conduct regular training sessions for your workforce to keep them updated on the latest technologies and quality standards.

- Utilize real-time monitoring tools to track production processes and detect anomalies as they occur.

- Foster open communication channels for feedback, allowing teams to address quality concerns promptly.

By taking these steps, Chinese manufacturers can reinforce their commitment to quality, ensuring that they remain trusted partners in the plastic mold industry.

Unwavering Quality from Trusted Chinese Manufacturers in Best Plastic Mold Solutions - Steps to Ensure Consistent Quality in Plastic Mold Production

| Manufacturer Type | Quality Control Measures | Materials Used | Production Capacity (units/month) | Lead Time (weeks) |

|---|---|---|---|---|

| OEM Manufacturer | ISO 9001 Certified, In-Process Inspection | ABS, PC, PA | 50,000 | 6 |

| Tooling Specialist | SPC, FMEA, Final Inspection | PP, POM, PVC | 30,000 | 8 |

| Custom Mold Maker | CMM Measurement, Process Audits | PET, HIPS, LDPE | 20,000 | 10 |

| Plastic Injection Molder | 6 Sigma, Regular Training | PS, PETG, TPE | 80,000 | 5 |

Building Long-Term Partnerships with Trusted Chinese Mold Suppliers

Building long-term partnerships with trusted Chinese mold suppliers is essential for businesses seeking reliable and high-quality plastic mold solutions. Establishing these relationships allows companies to benefit from consistent production quality, reduced lead times, and competitive pricing. Trusted suppliers not only understand the intricacies of mold manufacturing but also prioritize communication and customer service, fostering a collaborative environment.

**Tips:** When selecting a mold supplier, consider their experience in the industry and seek testimonials from past clients. Ask for samples of their work to assess the precision and quality of their molds before making a commitment. Additionally, establish clear communication channels to ensure that both parties align on project goals and expectations.

Choosing the right partner can also lead to innovation in your products. Engaging with suppliers who are invested in your success will encourage them to contribute ideas that enhance both functionality and marketability. Regular feedback sessions can be instrumental in refining processes and exploring new technologies together.

**Tips:** Schedule periodic review meetings to discuss ongoing projects and address any concerns proactively. This not only builds trust but also ensures both parties remain dedicated to mutual growth and success in the competitive landscape of plastic mold solutions.